Film bulk acoustic resonator structure based on all metal Bragg reflection layer

A Bragg reflector, thin-film bulk acoustic wave technology, applied in impedance networks, electrical components, sustainable buildings, etc., can solve the problems of large differences in thermal expansion coefficients of aluminum and tungsten, device failure, large differences in thermal expansion coefficients, etc., to reduce thermal shock. Inconsistent with the coefficient of thermal expansion, improving power capacity and excellent heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

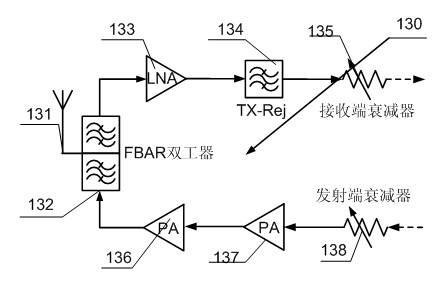

[0024] Such as figure 1 Shown is the radio frequency module block diagram of the wireless communication base station based on the FBAR technology of the present invention, the wireless communication base station 130 includes an antenna 131, an FBAR array duplexer 132, a low noise amplifier 133, a transmit signal suppression filter 134, and a receiving end attenuation A device 135, and a transmitter attenuator 138, a power amplifier 1 137, and a power amplifier 2 136 are connected in sequence.

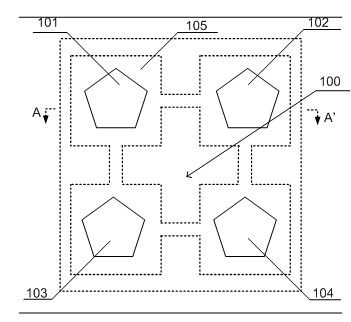

[0025] Wherein, the FBAR array duplexer 132 is as figure 2 As shown, the FBAR array duplexer 132 is composed of a transmitting link (Tx) and a receiving link (Rx), including an antenna terminal 121, a receiving terminal 122, a transmitting terminal 123, a receiving link series FBAR group 124, a receiving link A parallel FBAR group 125 , a transmission chain parallel FBAR group 126 , a transmission chain series FBAR group 127 , and a quarter transmission line 128 are formed.

[0026] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com