Stress-alleviating agent comprising plant-derived polyamine-containing extract as active ingredient

A plant-derived, amine extract technology, applied in the direction of organic active ingredients, medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, etc., can solve the problem of unknown anti-stress effects or stress relief of polyamines effect and other problems, to achieve the effect of excellent stress reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

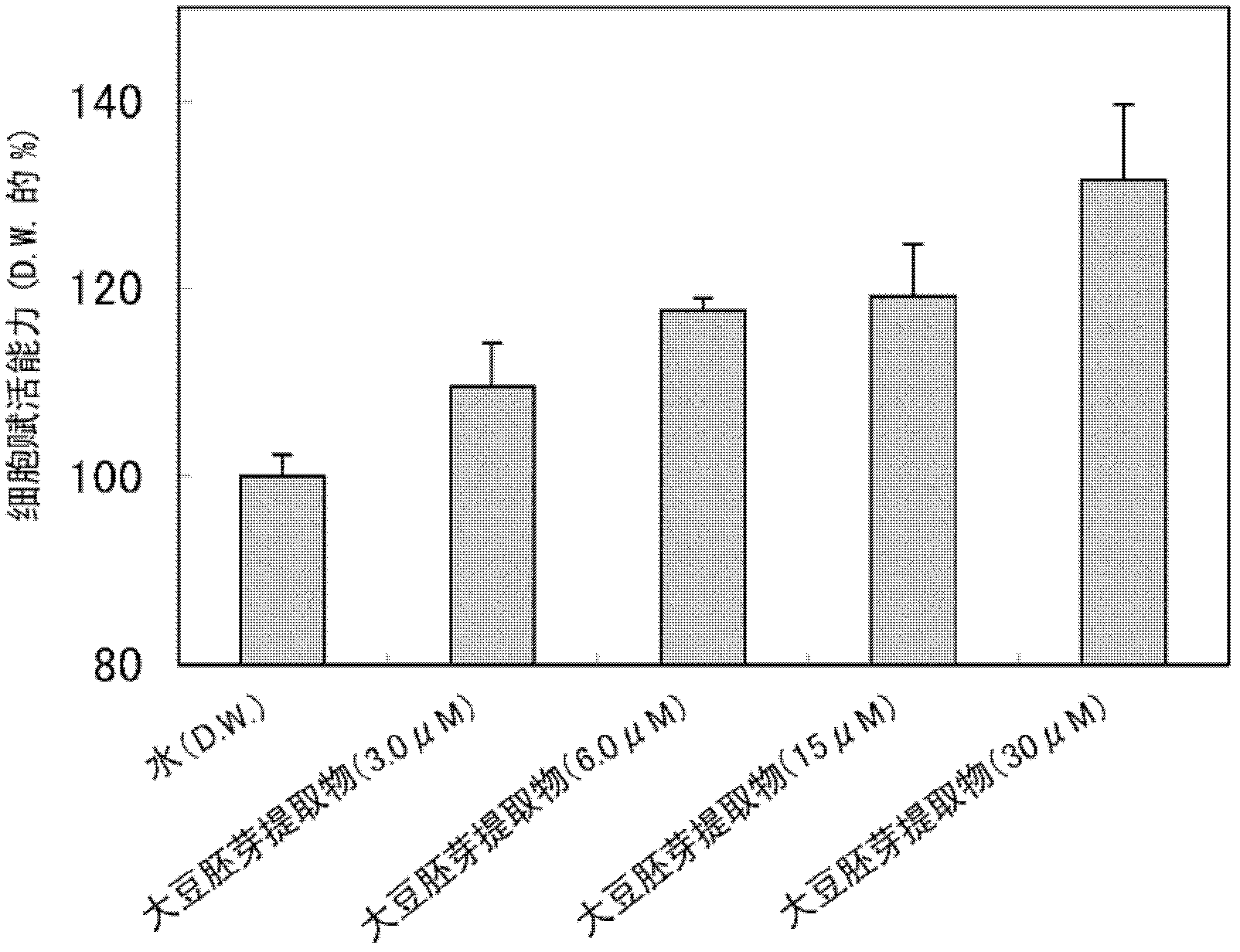

[0101] (Example 1A: Preparation of soybean-derived polyamine-containing extract)

[0102] Diluted internal standard solution (1,7-diaminoheptane; internal standard amount = 1200 nmol) and 500 mL of 5% perchloric acid aqueous solution were added to 100 g of soybean germ (manufactured by FOR YOU corporation) and left to stand at room temperature for 1 hour . The resulting solution was then mixed with 16 g of Polyclar VT (manufactured by ISP Inc.) as a polyphenol adsorbent. Soybean germ was thoroughly pulverized with a blender mixer, and then extracted under acidic conditions by standing at room temperature for 30 minutes. The pulverized material was subjected to centrifugation at 2°C and 22,000 xg for 20 minutes, and the liquid fraction was collected. The liquid fraction was neutralized with 30% sodium hydroxide solution. The resulting solution was defined as plant extract (soybean germ extract; LGS). The plant extract contained in total 57.1 mg of polyamines: 23.5 mg of put...

Embodiment 1B

[0103] (Example 1B: Preparation of soybean-derived polyamine-containing extract)

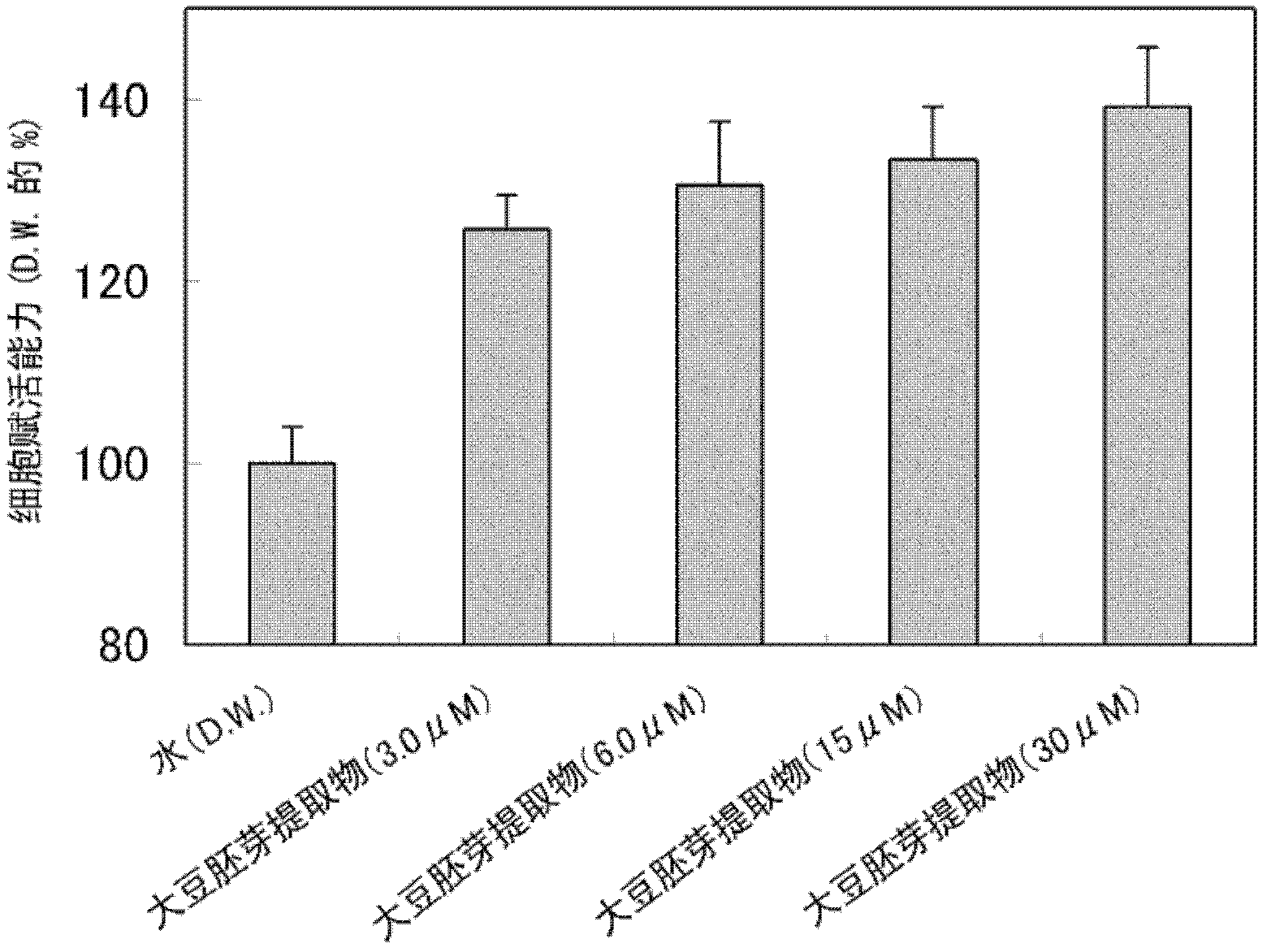

[0104] Soybean germ samples (1 kg each, soybean germ powder manufactured by FOR YOU corporation) were mixed with 0.1N, 0.5N and 1N hydrochloric acid solutions (6 L each). Each of the resulting solutions was then mixed with 80 g of Divergan F (manufactured by BASF) serving as a polyphenol adsorbent and extracted under acidic conditions by stirring at room temperature for 2 hours with a Three-one Motor. The stirred material was centrifuged at 4°C and 12,000 xg for 30 minutes and the liquid fraction was collected. The liquid fraction was neutralized with 30% sodium hydroxide solution. The resulting solution was then subjected to centrifugation at 4° C. and 12,000×g for 30 minutes and the liquid fraction was collected. This solution was defined as plant extract (soybean germ extract; LGS).

[0105] The plant extract according to 0.1 N hydrochloric acid contained in total 416.1 mg of polyamines: 2...

Embodiment 1C

[0107] (Example 1C: Preparation of soybean-derived polyamine-containing extract)

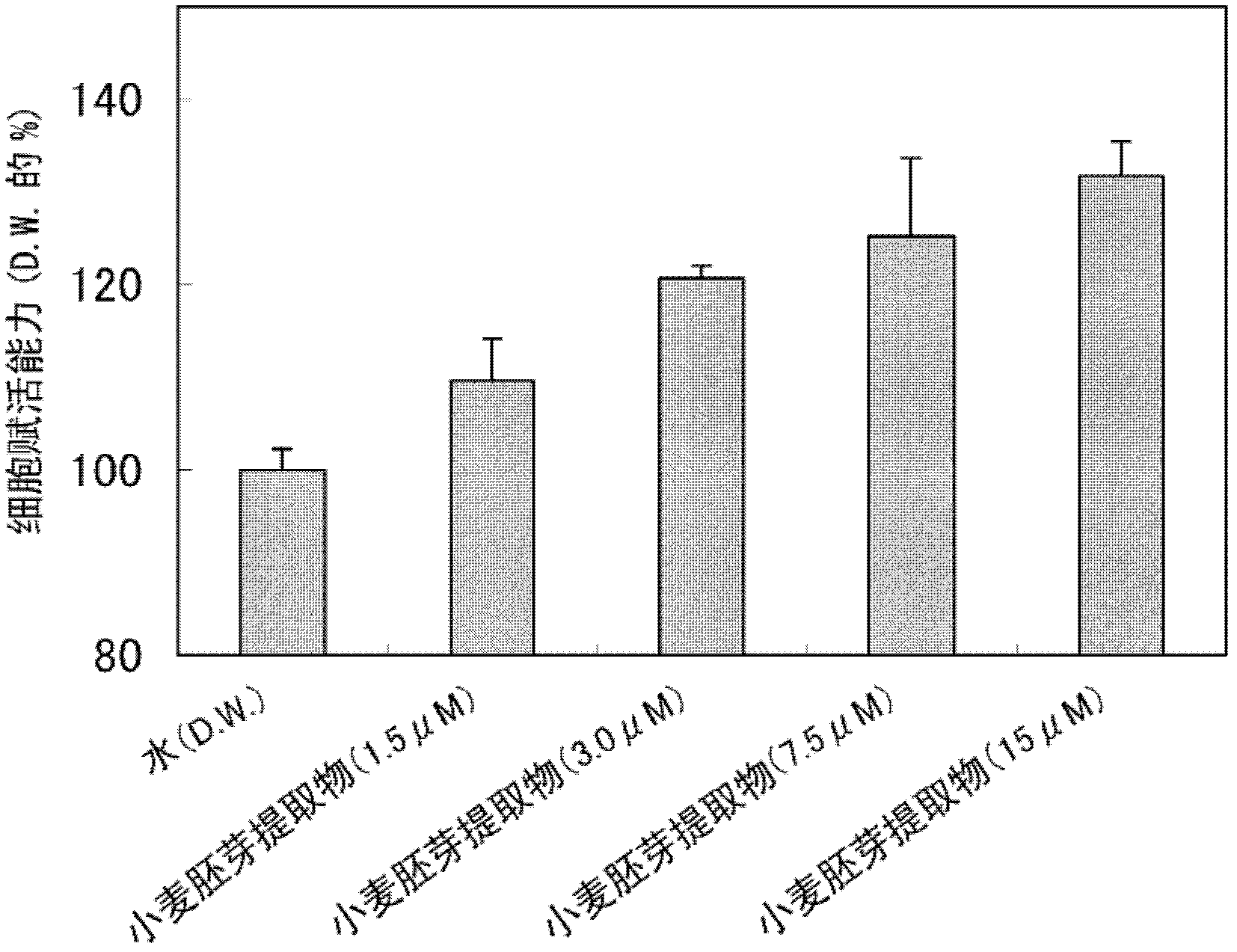

[0108] Soybean germ samples (1 kg each, soybean germ powder manufactured by FOR YOU corporation) were mixed with 0.1N, 0.5N and 1N sulfuric acid solutions (6 L each). Each of the resulting solutions was then mixed with 80 g of Divergan F (manufactured by BASF) serving as a polyphenol adsorbent and extracted under acidic conditions by stirring at room temperature for 2 hours with a Three-one Motor. The stirred material was centrifuged at 4°C and 12,000 xg for 30 minutes and the liquid fraction was collected. The liquid fraction was neutralized with 30% sodium hydroxide solution. The resulting solution was then subjected to centrifugation at 4° C. and 12,000×g for 30 minutes and the liquid fraction was collected. This solution was defined as plant extract (soybean germ extract; LGS).

[0109] The plant extract according to 0.1 N sulfuric acid contained in total 421.6 mg of polyamines: 220.8 mg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com