Bio-trickling filtration device and method for treating organic waste gases

A technology of organic waste gas and biological trickling filtration, which is applied in separation methods, chemical instruments and methods, and air quality improvement, etc., can solve problems such as hindering treatment efficiency, long waste gas treatment time, and unsatisfactory organic waste gas removal rate, and achieves convenient operation. , Stable treatment of organic waste gas, high removal load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

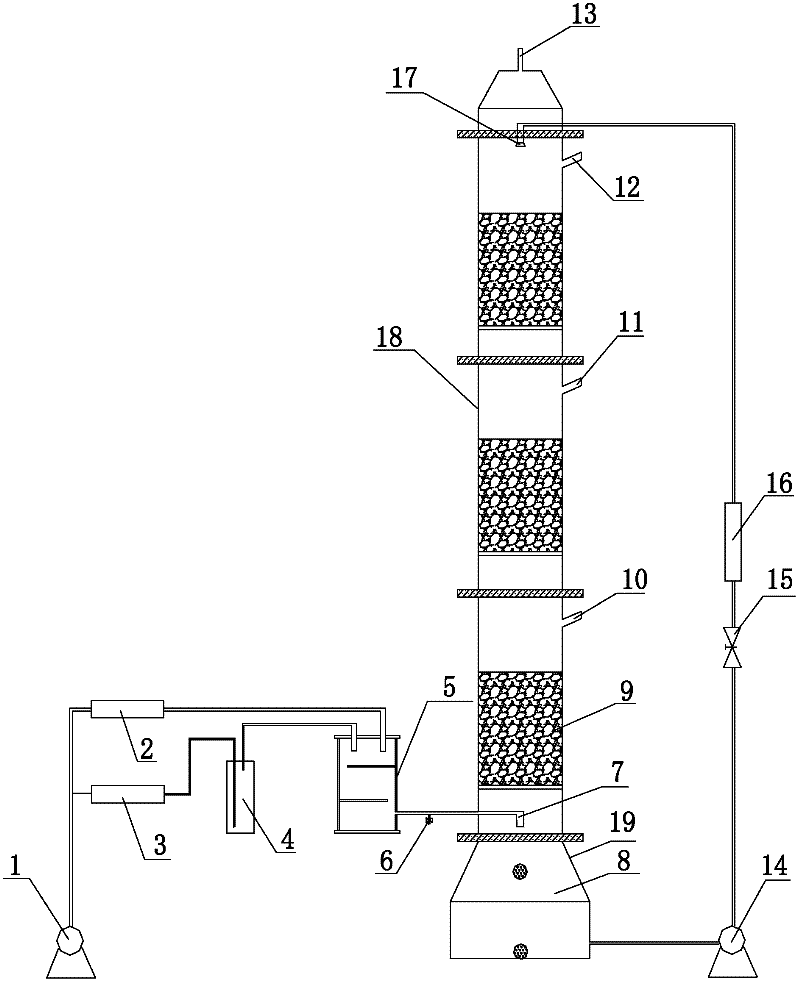

[0046] Such as figure 1 As shown, the bio-trickling filter device for treating organic waste gas of the present invention includes a bio-trickling filter tower 18 with an air outlet 13 at the top and an air inlet 7 at the bottom, and a bio-trickling filter tower 18 equipped with a biological filler 9. The bottom of 18 is used to support and fix the base 19, the liquid circulation device and the gas distribution system of the biological trickling filter tower 18, and the liquid circulation device is connected to the top and the bottom of the biological trickling filter tower 18 respectively. The base 19 is provided with a liquid storage tank 8, and the liquid storage tank 8 is provided with a corresponding water inlet and a water discharge port, and the base 19 and the liquid storage tank 8 can adopt an integral design.

[0047] The air inlet 7 of the bio-trickling filter tower 18 is connected with a gas distribution system, and the gas distribution system includes an electroma...

Embodiment 2

[0060] (1) After the bio-trickling filter device for treating organic waste gas of embodiment 1 is stabilized, the ortho-xylene waste gas is processed:

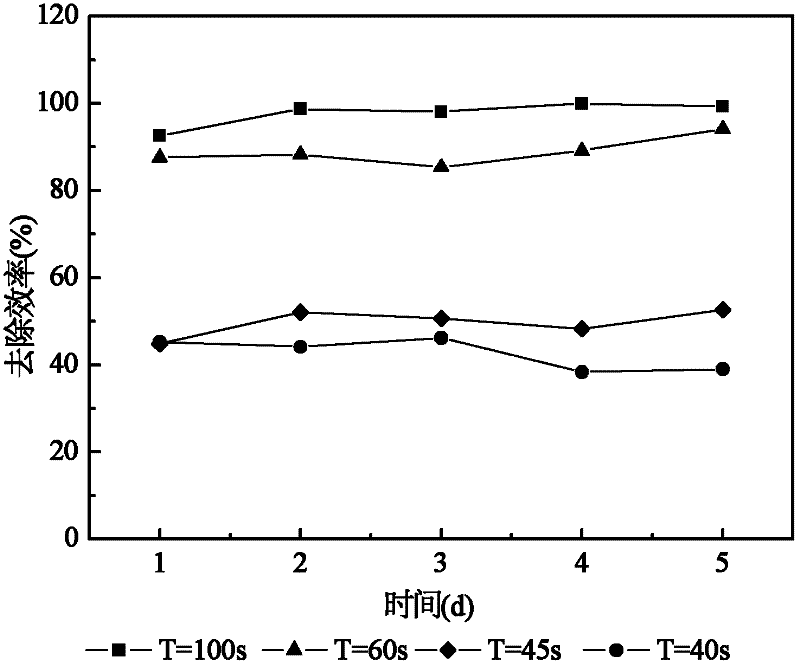

[0061] At room temperature 25°C, without adding Tween60, the waste gas of o-xylene composed of air and o-xylene gas is introduced through the gas distribution system; the residence time of the gas in the empty tower is 100s, 60s, 45s, and 40s respectively; The concentration of o-xylene in the exhaust gas is 550-600mg / m 3 , the concentration is collected through the first gas sampling port 6, and the organic waste gas is collected and measured by a gas chromatographic hydrogen ion flame detector (FID); the spraying rate of the circulating fluid is 20L / h, and the circulating fluid is a carbon-free nutrient solution, and other parameters are implemented in the same way example 1.

[0062] (2) Under different empty tower gas residence times, each treatment of organic waste gas conditions was run for 5 days, and the concentration...

Embodiment 3

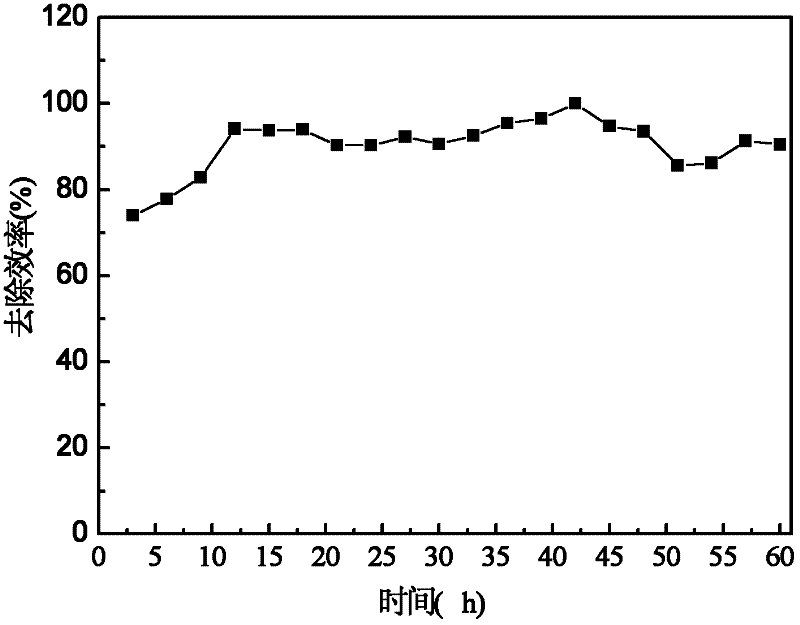

[0064] (1) After the bio-trickling filter device for treating organic waste gas of embodiment 1 is stabilized, the ortho-xylene waste gas is processed:

[0065] At room temperature of 25°C, without adding Tween60, the exhaust gas of o-xylene composed of air and o-xylene gas is introduced through the gas distribution system; the concentration of the exhaust gas of o-xylene at the 7 inlets is 550-600 mg / m 3, the concentration is collected through the first gas sampling port 6 for organic waste gas, and measured by a gas chromatographic hydrogen ion flame detector (FID). Parameter is the same as embodiment 1.

[0066] (2) Investigate the variation relationship of o-xylene degradation efficiency with time, measure the concentration of o-xylene in the tail gas at 13 places of the gas outlet of biological trickling filter tower 18 every 3 hours, obtain the degradation efficiency of o-xylene waste gas by calculation, specifically The result is as image 3 shown. Such as image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com