Preparation method and application of ractopamine molecularly-imprinted materials

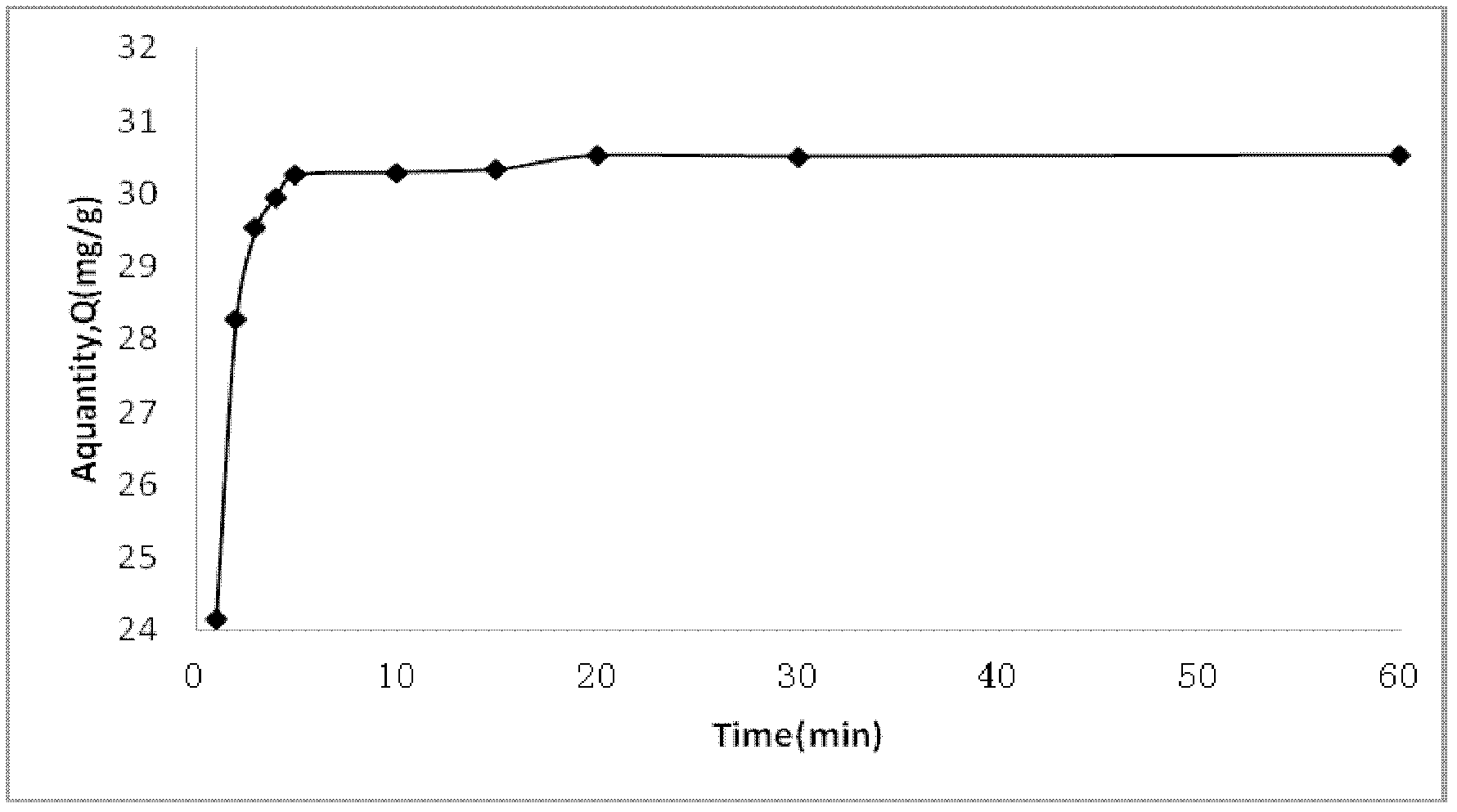

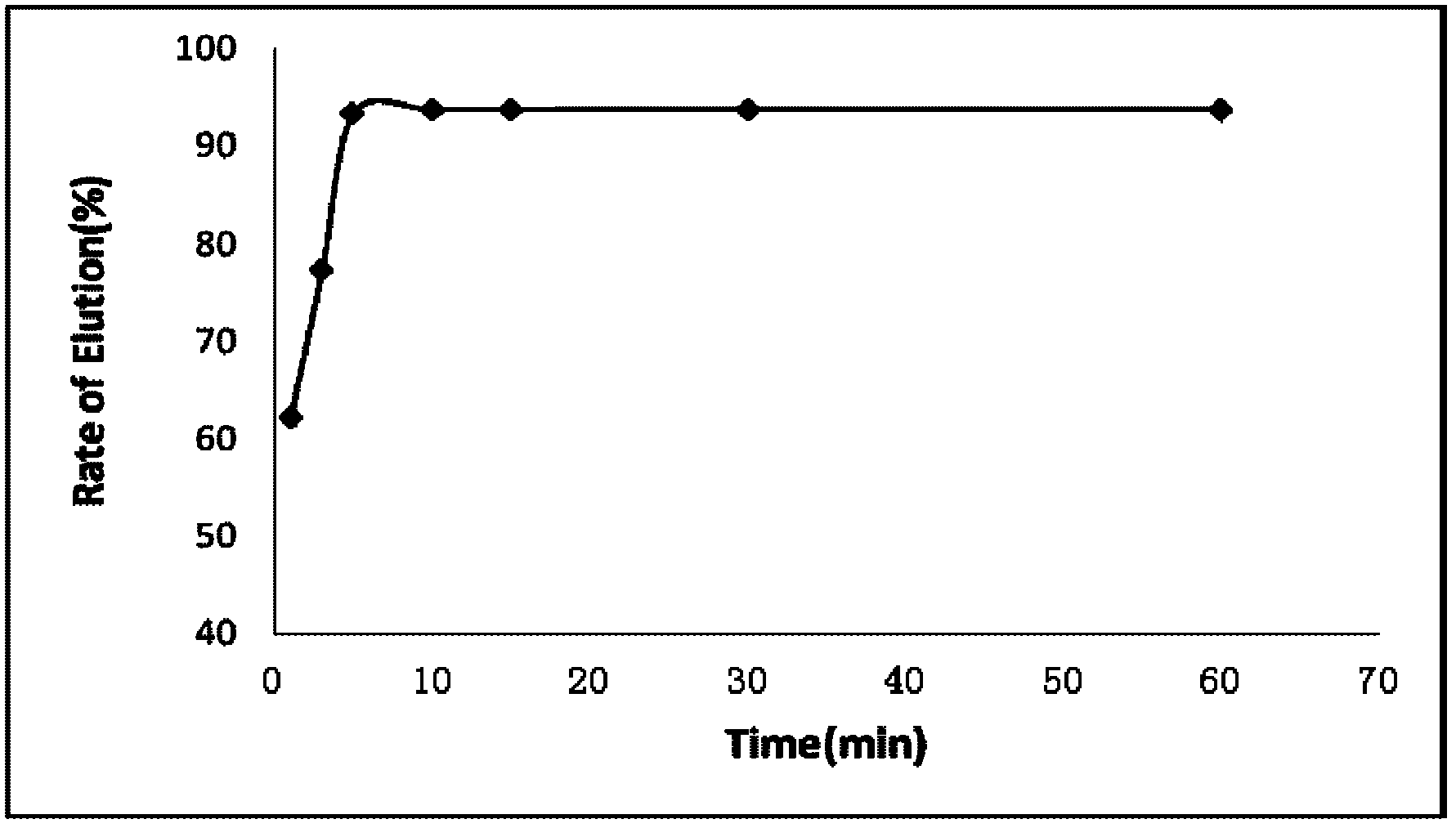

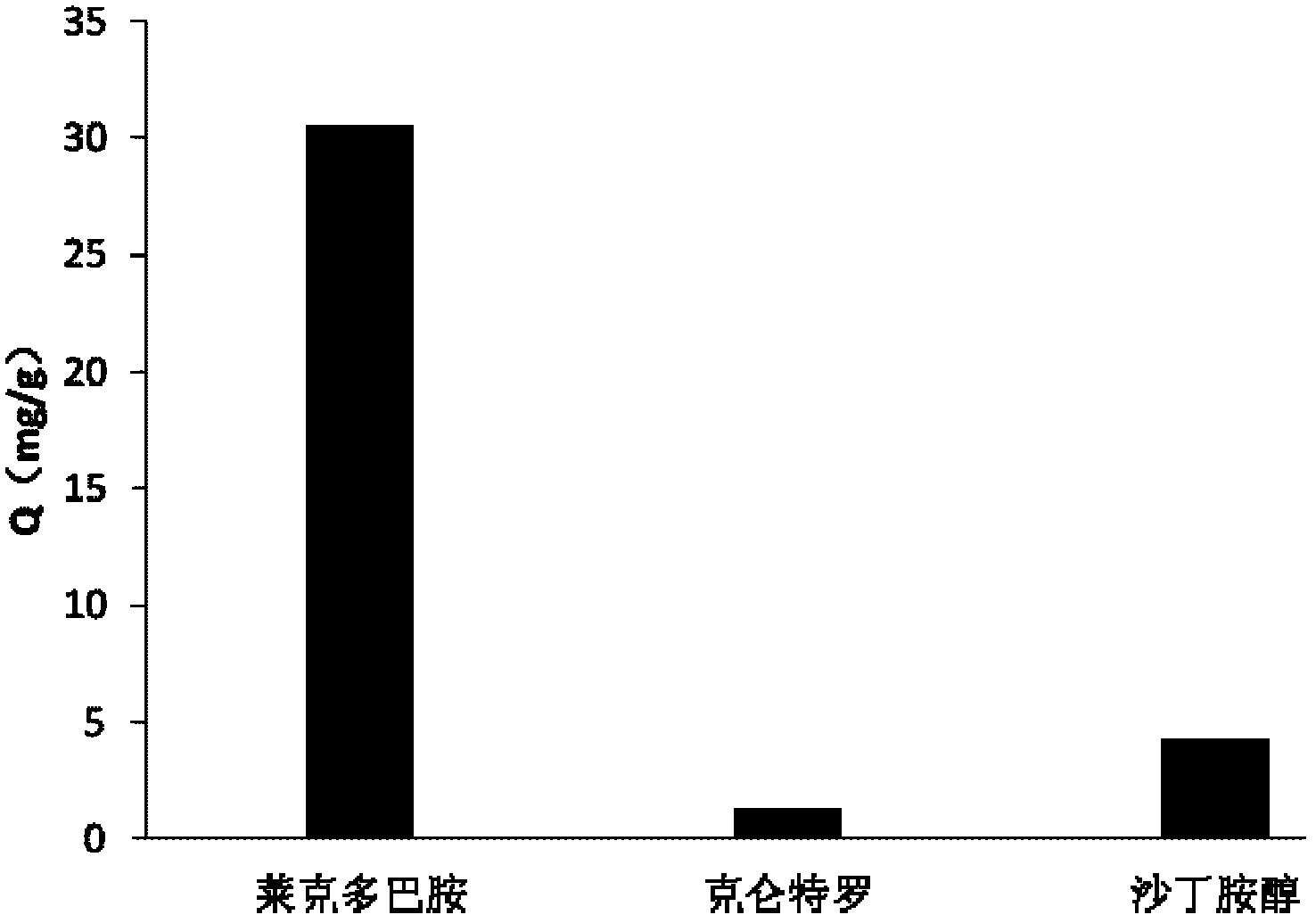

A ractopamine and molecular imprinting technology, applied in analytical materials, material separation, chemical instruments and methods, etc., can solve the problems of too deep embedding of template molecules, irregular shapes, low mechanical properties, etc., and achieve adsorption equilibrium in a short time. The effect of high binding affinity and short elution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 30 g of silica gel (particle size 5 μm), add 150 mL of 10% (v / v) methanesulfonic acid aqueous solution, stir at reflux temperature for 8 h, wash with distilled water until neutral, and dry at 65 ° C for 12 h to obtain activated silica gel. Add 5g of activated silica gel to 50mL of xylene and 2mL of water, add 7mL of γ-chloropropyltrimethoxysilane, stir and react at 80°C for 8h, wash the product with water, and dry at 65°C for 12h to obtain double-bonded silica gel . Add 50mL of 50% by weight polyethyleneimine aqueous solution with a molecular weight of 10000, 3g of CP-SiO 2 , stirred at 80°C for reaction, and the adsorption material was obtained after 8 hours. After washing with water, dry at 65°C for 12 hours before use. Take 50mL concentration as 500mg·L -1 ractopamine aqueous solution, add 1g of adsorbent material, stir for 1h, so that the adsorption of ractopamine by the adsorbent material reaches saturation, adjust the pH value of the system to make pH = 8...

Embodiment 2

[0037]Weigh 30 g of silica gel (particle size 40 μm), add 150 mL of 20% (v / v) hydrochloric acid aqueous solution, stir at reflux temperature for 8 hours, wash with distilled water until neutral, and dry at 65°C for 12 hours to obtain activated silica gel. Add 5g of activated silica gel to 50mL of xylene and 2mL of water, add 7mL of γ-bromopropyltrimethoxysilane, stir and react at 90°C for 8h, wash the product with water, and dry at 65°C for 12h to obtain a double-bonded silica gel . Add 50mL 50% polyethyleneimine aqueous solution with a molecular weight of 20000, 3g CP-SiO 2 , Stir at 80°C to react, and get the adsorption material after 8h. After washing with water, dry at 65°C for 12 hours before use. Take 50mL concentration to be 800mg·L -1 ractopamine aqueous solution, add 1g of adsorbent material, stir for 1h, so that the adsorption of ractopamine by the adsorbent material reaches saturation, adjust the pH value of the system to make pH = 9.0, add 0.2mL of ethylene glyc...

Embodiment 3

[0039] Weigh 30 g of silica gel (particle size 120 μm), add 150 mL of 10% (v / v) methanesulfonic acid aqueous solution, stir at reflux temperature for 8 h, wash with distilled water until neutral, and dry at 65 ° C for 12 h to obtain activated silica gel. Add 5g of activated silica gel to 50mL of xylene and 2mL of water, add 7mL of γ-chloropropyltrimethoxysilane, stir and react at 80°C for 8h, wash the product with water, and dry at 65°C for 12h to obtain double-bonded silica gel . Add 50mL50% polyethyleneimine aqueous solution with a molecular weight of 50000, 3g CP-SiO2 to the flask 2 , stirred at 90°C for reaction, and the adsorption material was obtained after 8 hours. After washing with water, dry at 65°C for 12 hours before use. Take 50mL concentration as 1000mg·L -1 ractopamine aqueous solution, add 1g of adsorbent material, stir for 1h, make the adsorption of ractopamine by the adsorbent material reach saturation, adjust the pH value of the system to make pH = 10.0, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com