Method for preparing monodisperse high-crystallinity silver powder

A high crystallinity, monodisperse technology, applied in the field of metal powder material preparation, can solve the problems of difficulty in meeting the market demand, low crystallinity of liquid phase powder, and low quality of silver powder products, and achieve rich product types, narrow particle size distribution, Use the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

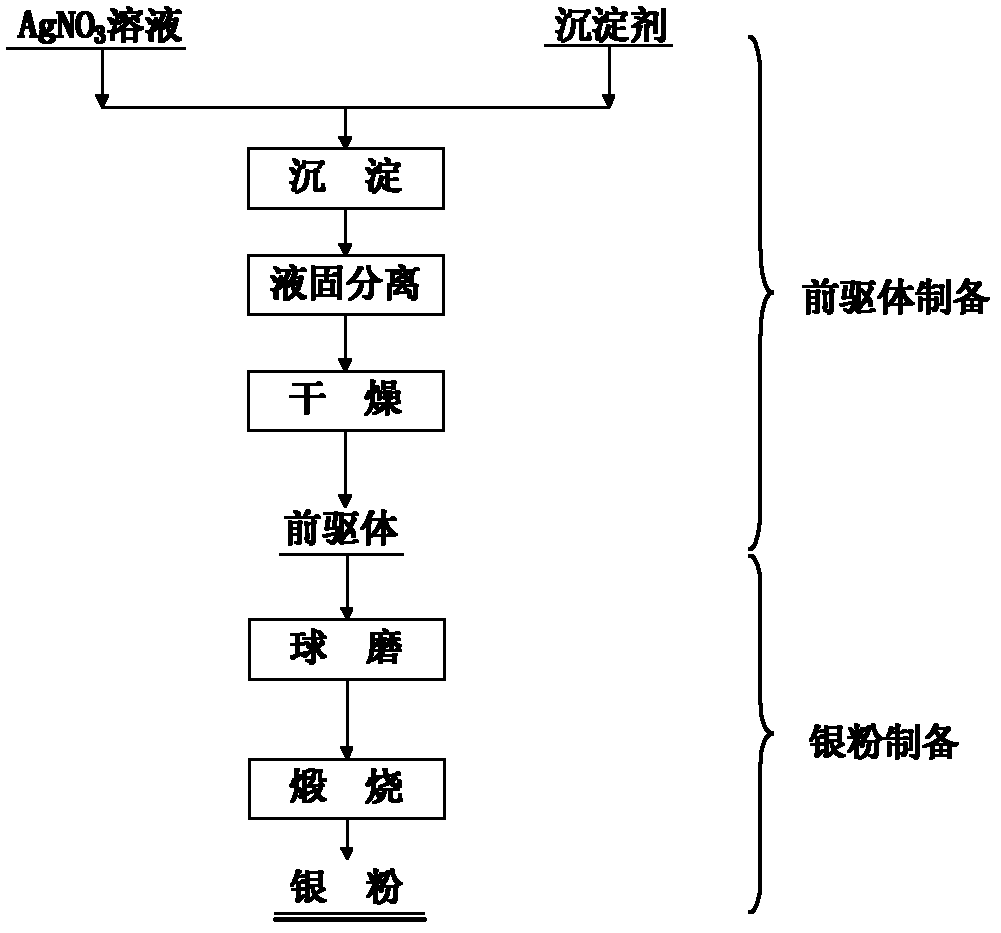

Method used

Image

Examples

Embodiment 1

[0036] (1) Precursor preparation

[0037] First prepare 100ml of silver nitrate solution A with a concentration of 1mol / L, and then prepare 100ml of 1.2mol / L NaOH mixed solution B, then control the reaction temperature at 80°C and the stirring speed at 200r / min, and feed solution B at a feeding speed of 5ml / min Added to solution A, after the addition was completed, aged for 1h. The precipitated product was washed 3 times with pure water, and vacuum-dried at 50°C to constant weight to obtain a precursor;

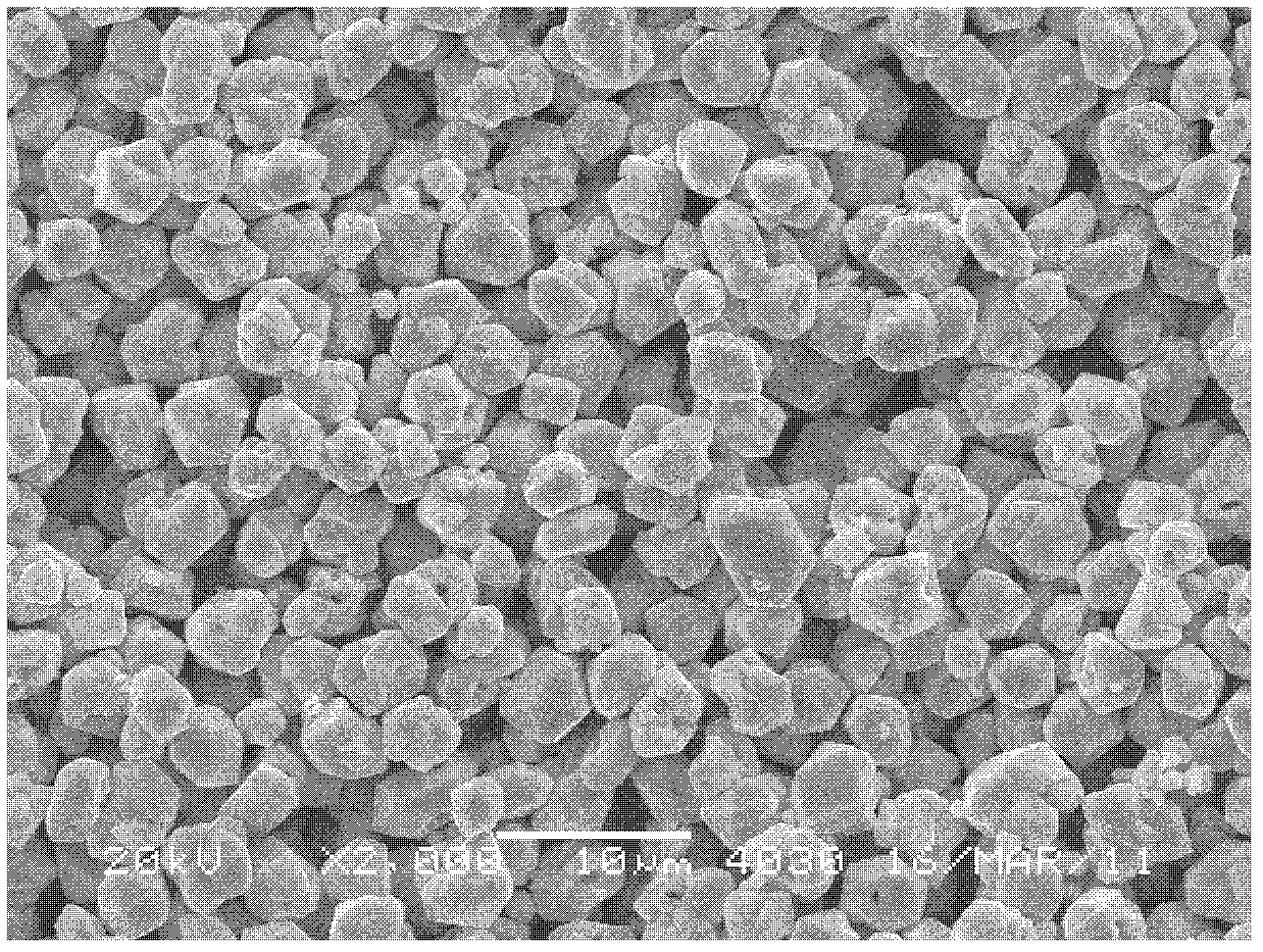

[0038] (2) Precursor reduction

[0039] First, the obtained precursor was dispersed by ball milling for 3 hours, the ball-to-material ratio was 10:1; the rotation speed was 400r / min, and then the precursor was added to the burning boat, put into the muffle furnace and calcined at 400°C for 2 hours to obtain the silver powder product. The resulting silver powder scanning electron microscope picture is as follows figure 2 As shown, the particle morphology is spherical or sp...

Embodiment 2

[0041] (1) Precursor preparation

[0042] First prepare 100ml of silver nitrate solution A with a concentration of 1.2mol / L, and then prepare 0.8mol / L Na 2 CO 3 Solution B 80ml, then control the reaction temperature at 60°C and the stirring speed at 200r / min, add solution B to solution A at a feeding speed of 30ml / min, and age for 1.5h after the addition. The precipitate was washed 3 times with pure water, and dried in vacuum at 50°C to constant weight to obtain the precursor;

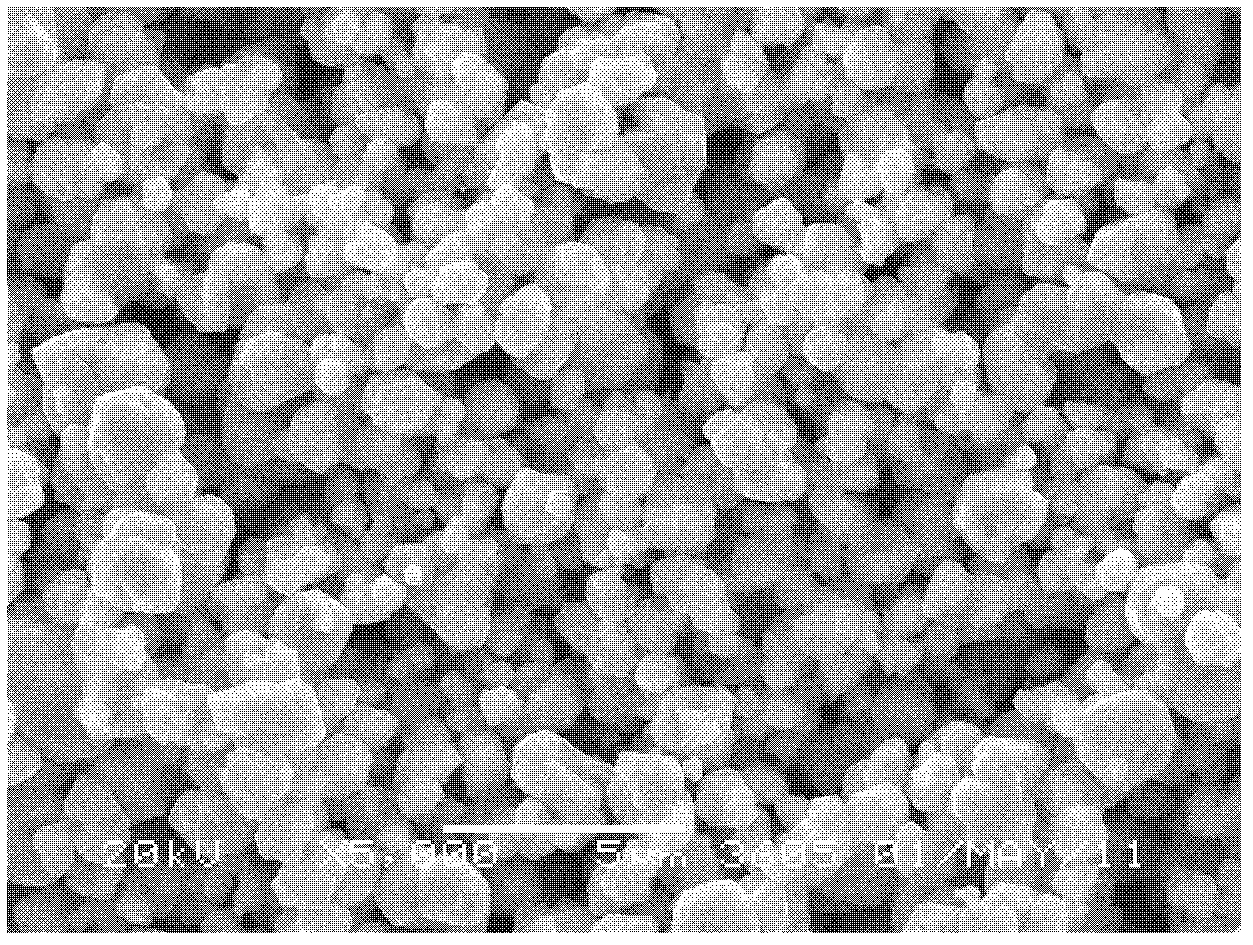

[0043] (2) Precursor reduction

[0044] First, the obtained precursor was dispersed by ball milling for 4 hours, the ball-to-material ratio was 30:1; the rotation speed was 300r / min, and then the precursor was added to a burning boat, placed in a muffle furnace and calcined at 350°C for 4 hours to obtain a silver powder product. The resulting silver powder scanning electron microscope picture is as follows image 3 As shown, the particle morphology is spherical or spherical, and the average particl...

Embodiment 3

[0046] (1) Precursor preparation

[0047] First prepare 100ml of silver nitrate solution A with a concentration of 2mol / L, and then prepare 1mol / L Na 2 C 2 o 4 Solution B 120ml, then control the reaction temperature at 55°C and the stirring speed at 300r / min, add solution B to solution A at a feeding speed of 50ml / min, and age for 2h after the feeding is completed. The precipitate was washed three times with pure water, and vacuum-dried at 50° C. to constant weight to obtain the precursor.

[0048] (2) Precursor reduction

[0049] First, the obtained precursor was dispersed by ball milling for 5 hours, the ball-to-material ratio was 50:1; the rotation speed was 500r / min, and then the precursor was added to a burning boat, placed in a muffle furnace and calcined at 450°C for 2 hours to obtain a silver powder product. The resulting silver powder scanning electron microscope picture is as follows Figure 4 As shown, the particle morphology is spherical or spherical, and the av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com