Polyester film for heddles and preparation method of polyester film

A technology of polyester film and polyester base film, applied in healds, chemical instruments and methods, textiles, etc., to achieve the effect of maintaining wear resistance, simple process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

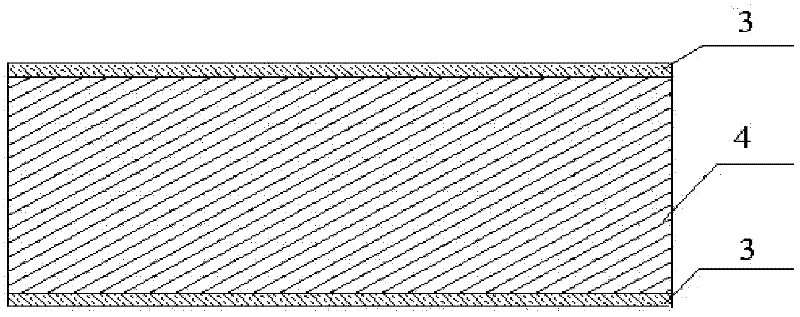

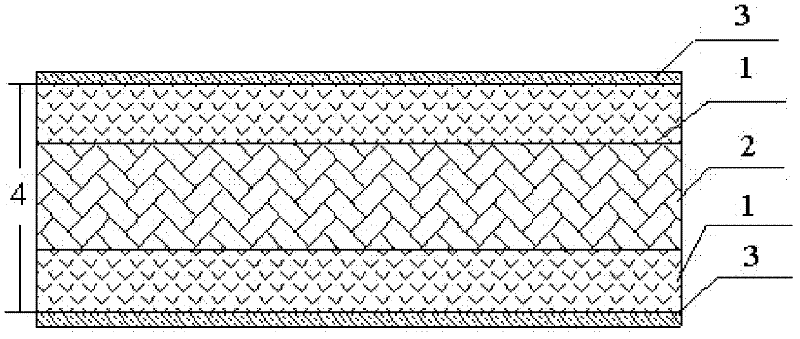

Image

Examples

preparation example Construction

[0040] The preparation method of the polyester film for healds provided by the invention comprises the following steps (except the thickness, the percentages are percentages by weight):

[0041] (1) Preparation of base film

[0042] After the polyester raw material is dried, it is melt-extruded through an extruder to form ABA three-layer co-extrusion. The resulting thick sheet is stretched 4 times in the longitudinal direction at 100°C, stretched 3.8 times in the transverse direction at 104°C, and heated at 225°C. Sizing treatment, winding after cooling to make the polyester base film; the polyester base film is an ABA three-layer structure, including A layer and B layer, B layer is a supporting layer, and a bright slice is selected, and A layer is Functional layer, including 46-70% polyester chips, 26-50% anti-blocking masterbatch and 2-8% antistatic masterbatch.

[0043] (2) Preparation of polyester film for heddles

[0044] Apply pigment to the surface of the base film ob...

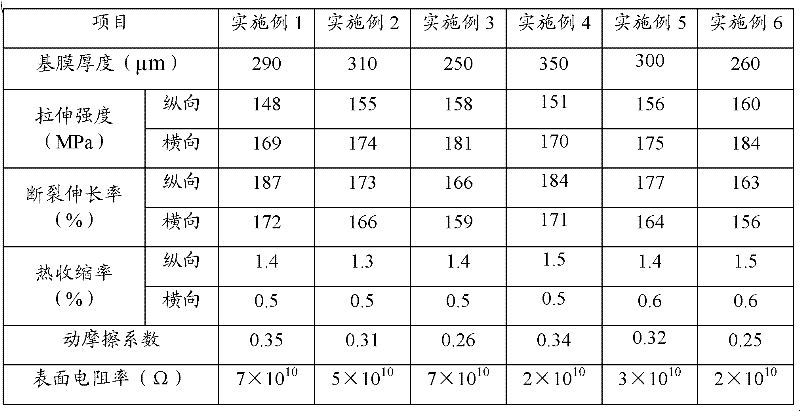

Embodiment 1

[0056] Prepare the polyester film for heald according to the above method, the two functional layers of the polyester base film contain 68% of semi-dull polyester chips, 30% of anti-blocking masterbatch, 2% of antistatic masterbatch; the obtained thickness is 290 μm Polyester base film.

[0057] Wherein, the content of silicon dioxide in the anti-blocking polyester masterbatch (anti-blocking masterbatch) is 0.4%, and the particle size of the silicon dioxide particles is 2-6 μm; the antistatic masterbatch contains 8% poly Ether antistatic agent; the coating solution includes 80% ethylene organosol and 20% fast red.

Embodiment 2

[0059] Prepare the polyester film for heald according to the above method, the two functional layers of the polyester base film contain 56% of semi-dull polyester chips, 42% of anti-blocking masterbatch, 2% of antistatic masterbatch; the obtained thickness is 310 μm Polyester base film.

[0060] Wherein, the content of silicon dioxide in the anti-blocking polyester masterbatch (anti-blocking masterbatch) is 0.5%, and the particle size of the silicon dioxide particles is 4-8 μm; the antistatic masterbatch contains 4% ion Type antistatic agent; the coating solution includes 85% ethylene organosol and 15% iron oxide yellow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap