Method for preparing graphite by compressing CO2 fluid under ultrasonic assistance

An ultrasonic and graphene technology, which is applied in the field of graphene prepared by compressing CO2 fluid assisted by ultrasonic waves, can solve the problems of reduced electrical performance, increased product area, and high cost, and achieves simple and easy post-processing, simple process, and easy operation. The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

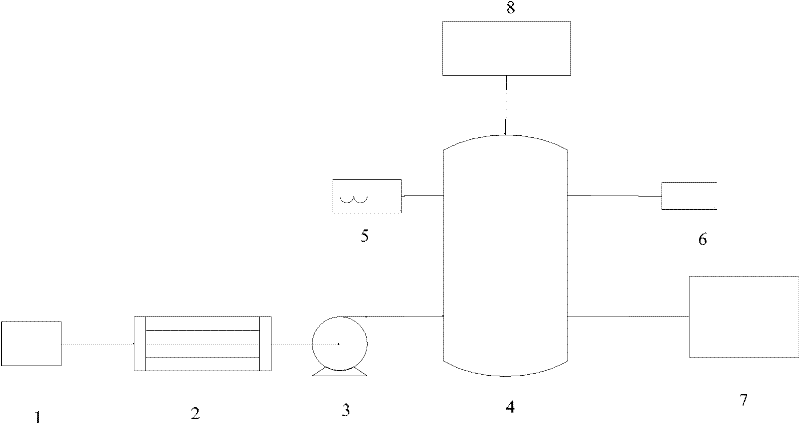

[0022] Add a certain amount of graphite powder and sodium lauryl sulfate to the reaction kettle 4, and pass into the compressed CO with a temperature of 35°C and a pressure of 9.0MPa from the side. 2 Fluid, hold pressure for 50min. And simultaneously turn on the ultrasonic instrument 8, the power is controlled at 100W, and the time is 45min. After the reaction is over, take out the material from the kettle, put it into a solution of sodium dodecyl sulfate with a certain concentration, obtain the primary product, and cool it down. Through testing and characterization, the obtained graphene accounts for about 70%, with excellent properties, most of which have a diameter of 0.5 to 2 microns, and the number of layers is about 5 to 9 layers. The transmission electron microscope photos of prepared graphene are as follows figure 1 shown.

Embodiment 2

[0024] Weigh a certain amount of graphite powder and sodium dodecylbenzenesulfonate and add them to the reaction kettle 4, and then feed into the compressed CO with a temperature of 35°C and a pressure of 10.0MPa from the side. 2 Fluid, hold pressure for 45min. And simultaneously turn on the ultrasonic instrument 8, the power is controlled at 250W, and the time is 30min. After the reaction, the materials are taken out and put into a solution of sodium dodecylbenzenesulfonate with a certain concentration to obtain primary products, which are then cooled. Through testing and characterization, the obtained graphene accounts for about 85% and has excellent properties. Most of the graphene has a diameter of 50-500 nanometers, the number of layers is about 3-8 layers, and the single-layer graphene accounts for about 25%.

Embodiment 3

[0026] A certain amount of graphite powder and sodium lauryl sulfate are added to the reaction kettle 4, and supercritical CO with a temperature of 40 ° C and a pressure of 11.0 MPa is introduced from the side. 2 Fluid, hold pressure for 30min. And at the same time turn on the ultrasonic instrument, the power is controlled at 600W, and the time is 20min. After the reaction is finished, the material is taken out and put into a solution of sodium dodecyl sulfate with a certain concentration to obtain the primary product, which is then cooled. Through testing and characterization, the obtained graphene has excellent properties, most of which have a diameter of 20-100 nanometers, and the number of layers is about 2-4, of which single-layer graphene accounts for about 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com