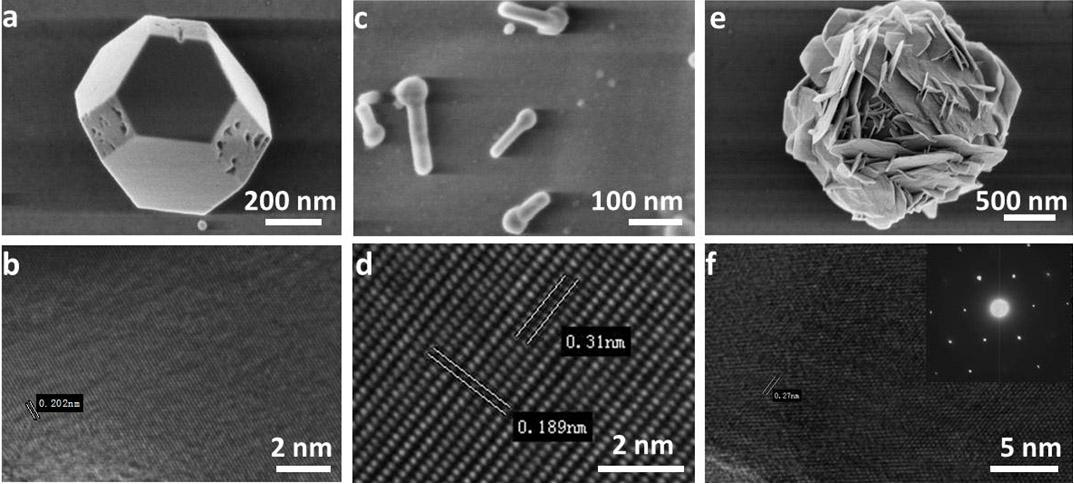

Method for preparing nanometer copper-sulfur compounds with controllable morphologies based on chemical vapor deposition method

A chemical vapor deposition, copper-sulfur compound technology, applied in copper sulfide, nanotechnology and other directions to achieve the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

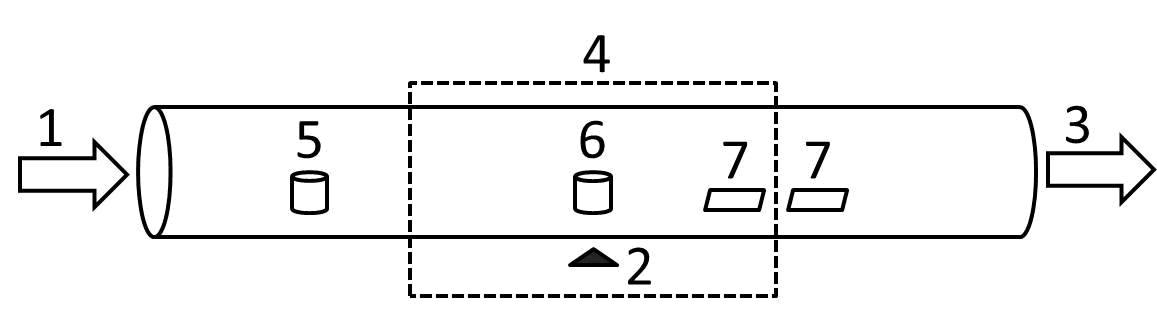

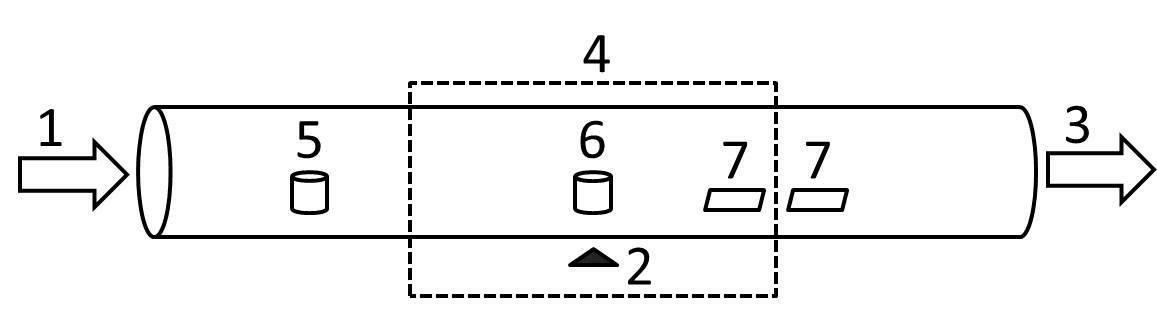

[0018] The invention discloses a method for preparing a copper-sulfur compound with controllable morphology based on a chemical vapor deposition method, which includes three parts: a reaction precursor sampling method, system pressure control, and system temperature regulation.

[0019] ①Injection of reaction precursors: solid or liquid reaction precursors are placed in a quartz boat, and the position of the quartz boat in the reaction zone can be adjusted arbitrarily; The inlet of the gas, the airflow velocity and the inlet time, etc.

[0020] ②System pressure control: The system pressure can be controlled between low pressure and high pressure. The low pressure is conducive to the cleaning of the reaction system and the timely extraction of the reactants, and the regulation of medium and high pressure is conducive to the regulation of product morphology.

[0021] ③System temperature control: The temperature of the reaction zone and the reaction product can be precisely cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com