Method for removing heavy metal from sludge

A heavy metal and sludge technology, applied in the field of environmental treatment, can solve the problems of high acid consumption, high cost and long time, and achieve the effect of less acid consumption, low cost and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

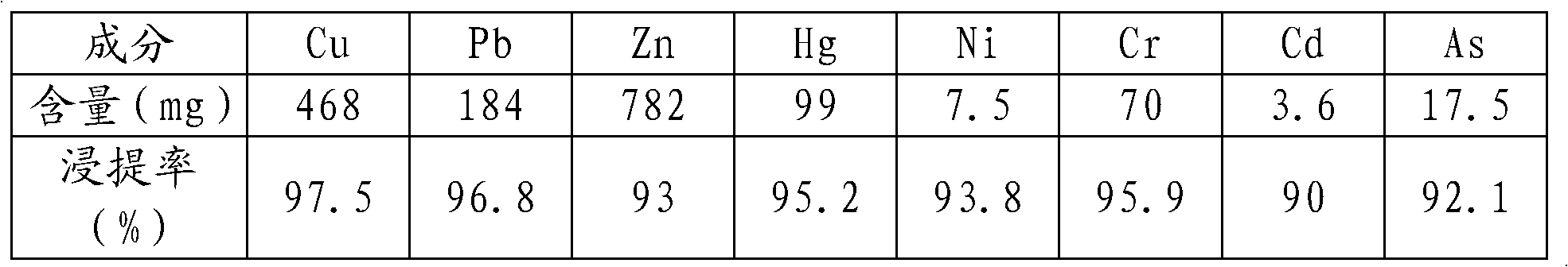

[0024] The sludge was taken from a sewage treatment plant in Xingsha, Hunan. After the wet sludge was dried, the heavy metal components of the dried sludge samples were analyzed, as shown in Table 1.

[0025] Table 1 Heavy metal composition analysis (mg / Kg) of sludge samples from a sewage treatment plant in Wuhan, Hubei

[0026] Element

Cu

Pb

Zn

Hg

Ni

Cr

CD

As

content

480

190

841

104

8

73

4

19

[0027] Take 1 kilogram of the original sludge and place it in a beaker, add 2L of 2mol / L citric acid solution, stir while adding the liquid, then adjust the pH to 5 with nitric acid and sodium hydroxide, and then add 0.5L of 27.5% citric acid Hydrogen peroxide, similarly, stir while adding liquid, and continue to stir for 20 minutes after adding liquid.

[0028] The above-mentioned sludge solid-liquid mixture is heated by microwave, and after being heated to 50°C, it is kept for 1...

Embodiment 2

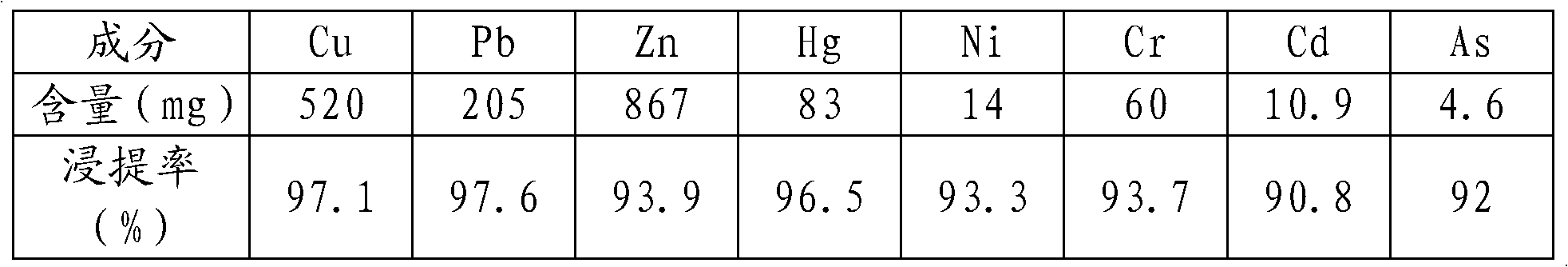

[0034] The sludge was taken from the wastewater treatment plant of a printing and dyeing enterprise in Zhijiang, Hubei. After the wet sludge was dried, the heavy metal components of the dried sludge samples were analyzed, as shown in Table 3.

[0035] Table 3 Heavy metal composition analysis (mg / Kg) of sludge samples from a wastewater treatment plant of a printing and dyeing enterprise in Zhijiang, Hubei

[0036] Element

Cu

Pb

Zn

Hg

Ni

Cr

CD

As

content

535

210

923

86

15

64

12

5

[0037] Take 1 kg of the original sludge and place it in a beaker, add 2L of 3mol / L citric acid solution, stir while adding the liquid, then adjust the pH to 5 with nitric acid and sodium hydroxide, and then add 0.5L of 33% citric acid solution Hydrogen peroxide, similarly, stir while adding liquid, and continue to stir for 20 minutes after adding liquid.

[0038] The above-mentioned sludge solid-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com