P-perfluorous nonene oxygen group benzene sulfonic acid polyethylene glycol ester and preparation method as well as application thereof

A technology of perfluorononenyloxybenzenesulfonyl chloride and nonenyloxybenzenesulfonic acid, which can be used in the preparation of sulfonic acid esters, chemical instruments and methods, transportation and packaging, etc., can solve the problems of low surface activity, etc. Application prospect, simple synthesis method, high surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

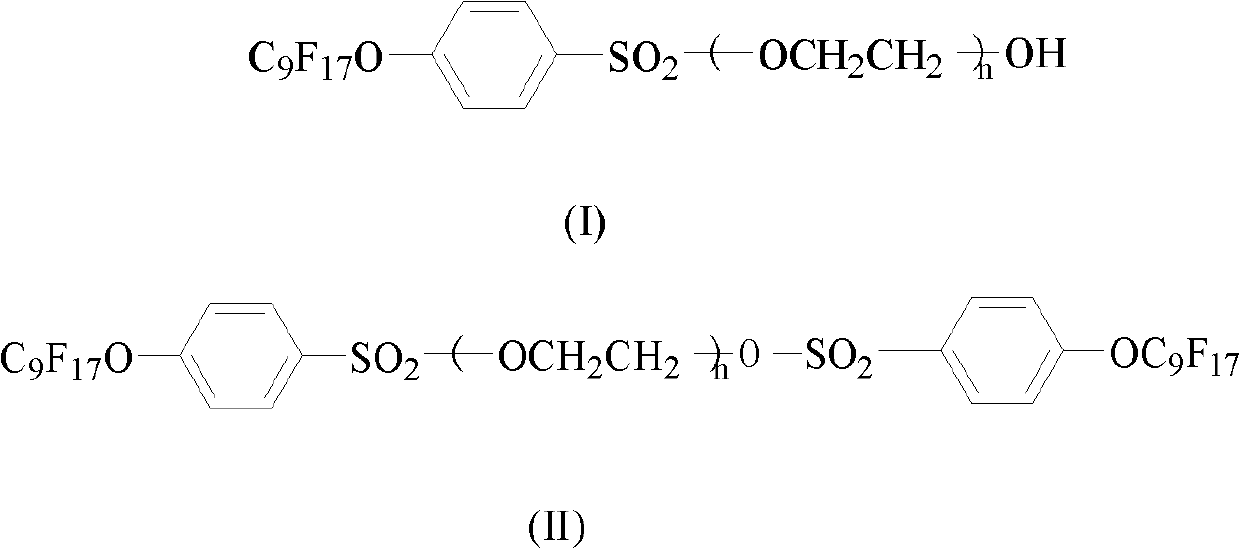

[0023] In a 250mL four-necked flask equipped with a stirrer, a thermometer, a dropping funnel and a reflux condenser, add 50mL (0.5mol) ethyl acetate, 30g (0.05mol) polyethylene glycol-600, 5.06g (0.05mol) Triethylamine, stirred, cooled to 10°C, slowly added dropwise 31.1g (0.05mol) p-perfluorononenyloxybenzenesulfonyl chloride in 50mL CCl 4 The solution was added dropwise for about 30 minutes, and the stirring reaction was continued at 10°C for 24 hours. Distilled under reduced pressure to remove the solvent to obtain a yellow viscous paste (a mixture of monoester and diester). The surface tension of the 0.5 g / L product aqueous solution measured at 20° C. was 22.6 mN / m.

[0024] Product structure characterization:

[0025] FT-IR (KBr, cm-1): 3424, 2873, 1663, 1488, 1282, 1180, 1092, 971, 838, 737.

[0026] 19 F NMR δ(CDCl 3 ): -169.8, -167.7, -72.8, -71.5, -56.3.

Embodiment 2

[0028] The reaction was carried out according to Example 1, but the solvent 50mL ethyl acetate was changed to 150mL N,N-dimethylformamide, and the amount of p-perfluorononenyloxybenzenesulfonyl chloride was changed to 155.67g (0.25mol), 5.06 The g of triethylamine was changed to 42.5 g of piperidine (0.50 mol), the reaction temperature was changed to 150° C., and the reaction time was changed to 1 h.

[0029] A yellow viscous paste (a mixture of monoester and diester) was obtained, and the surface tension of a 0.5 g / L product aqueous solution measured at 20° C. was 20.6 mN / m.

Embodiment 3

[0031] The reaction was carried out according to Example 1, but the solvent 50mL ethyl acetate was changed to 75mL N,N-dimethylformamide, and the amount of p-perfluorononenyloxybenzenesulfonyl chloride was changed to 34.2g (0.055mol), 5.06 The g of triethylamine was changed to 13.9 g of sodium bicarbonate (0.165 mol), the reaction temperature was changed to 50° C., and the reaction time was changed to 7 hours.

[0032] A yellow viscous paste (a mixture of monoester and diester) was obtained, and the surface tension of a 0.5 g / L product aqueous solution measured at 20° C. was 21.5 mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com