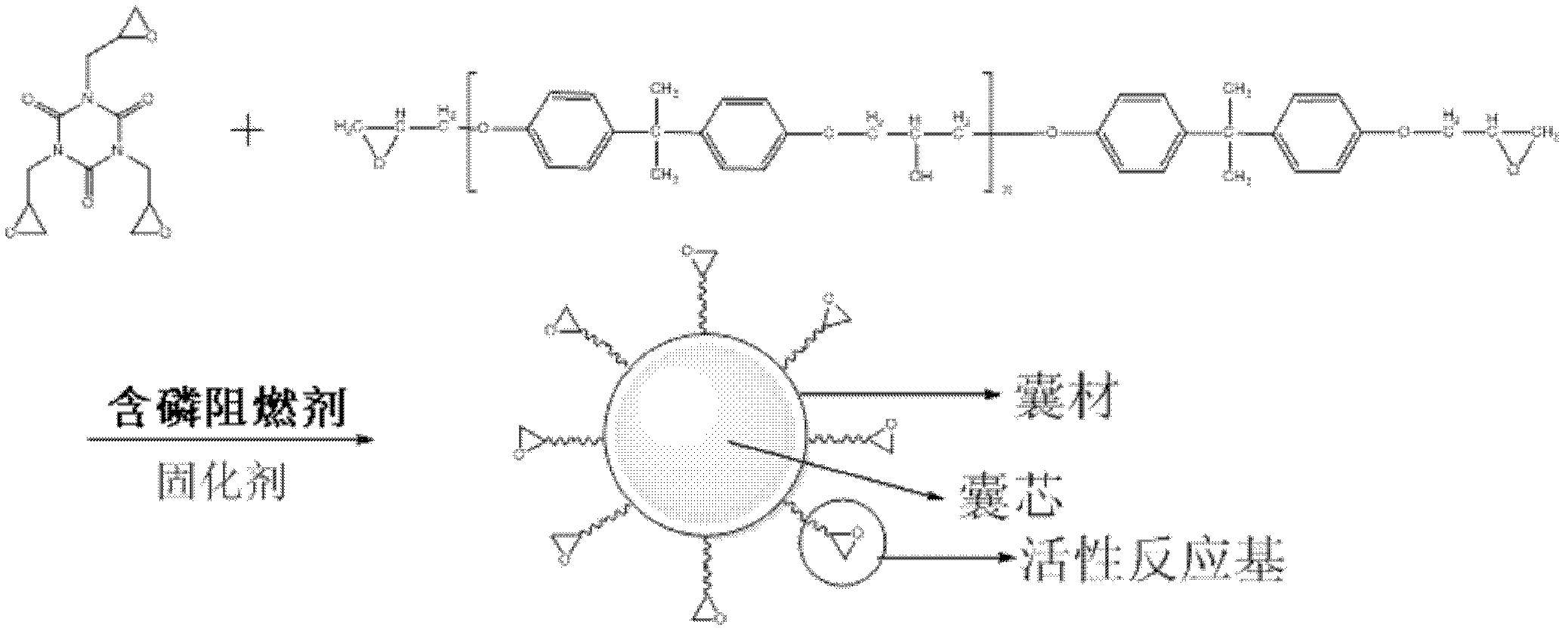

Epoxy resin reaction-type microcapsule fire retardant and preparation method thereof

A technology of epoxy resin and flame retardant, which is applied in the field of epoxy resin reactive microcapsule flame retardant and its preparation, which can solve the problems of adverse effects on physical and mechanical properties of materials, insignificant matrix compatibility, etc., and achieve improved stability Sexuality and physical and mechanical properties, improve performance and use stability, improve the effect of surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

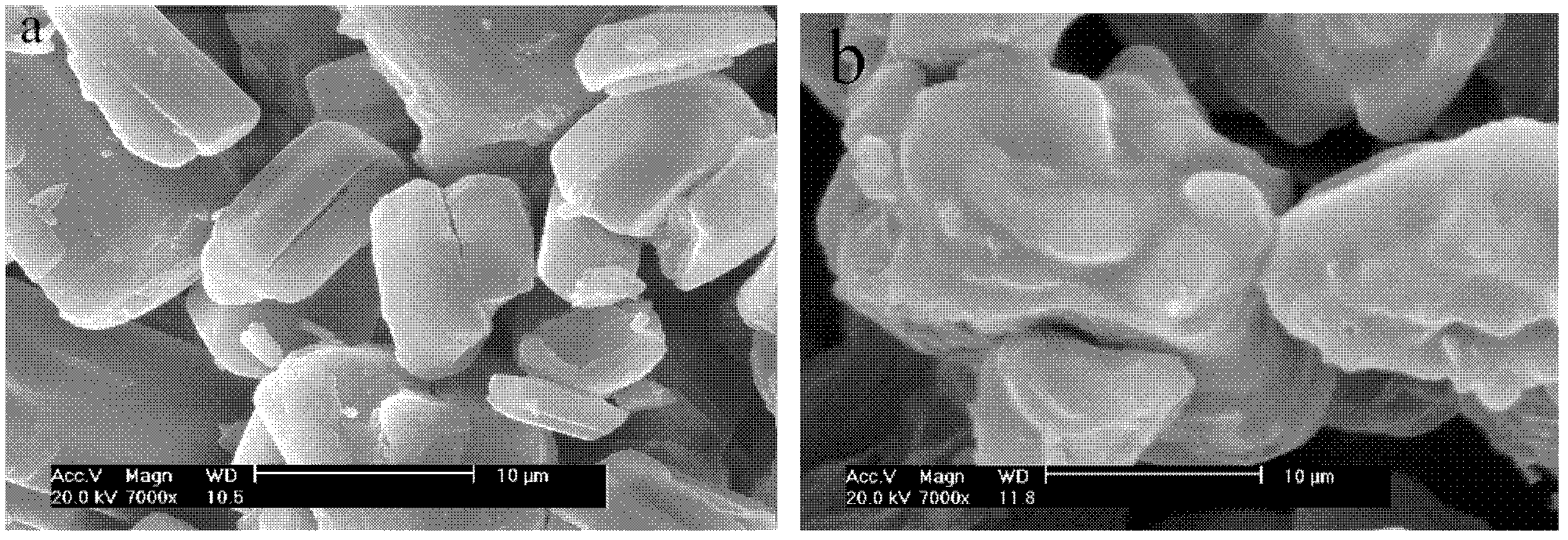

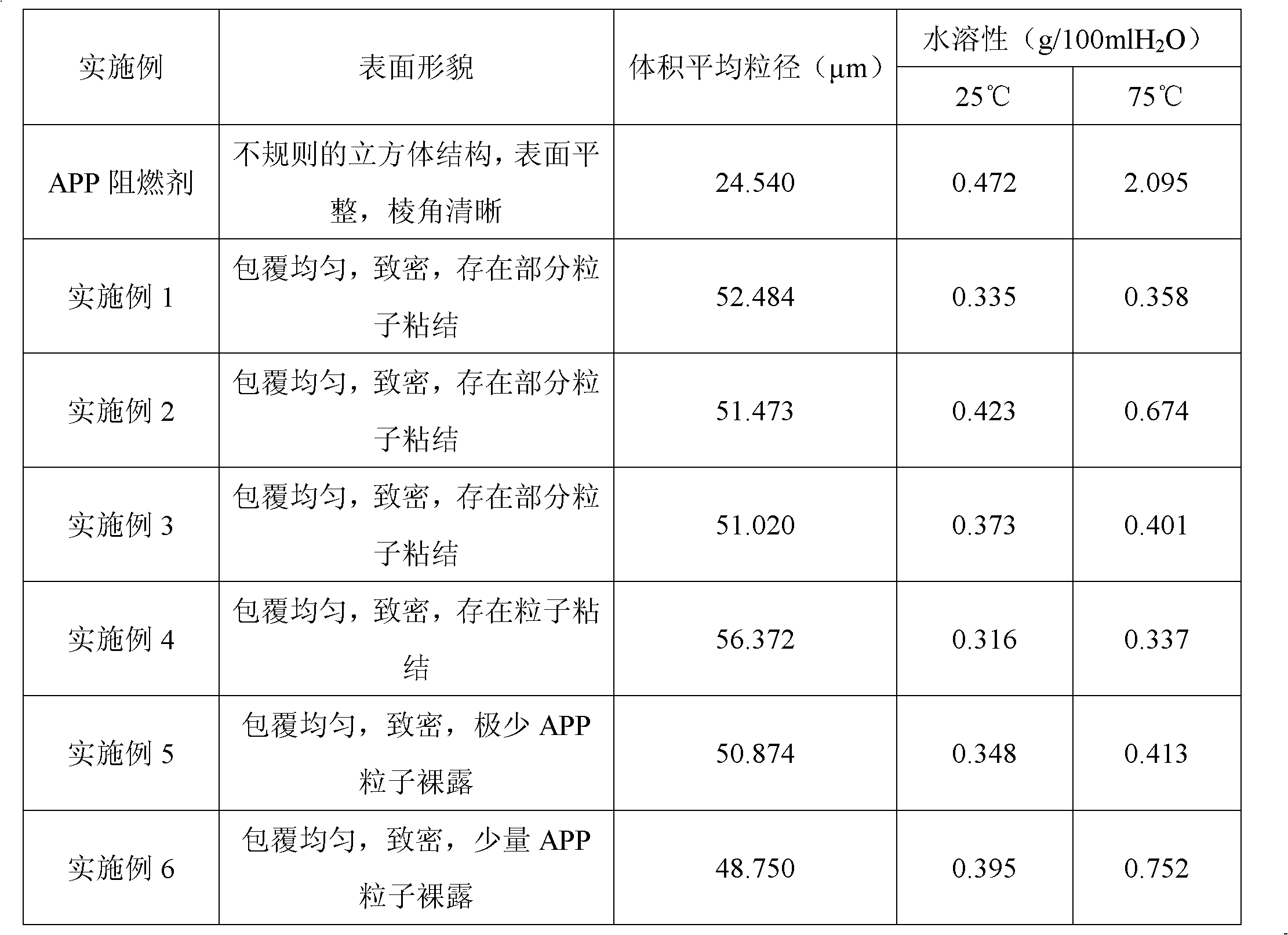

Embodiment 1

[0030] In a reactor equipped with a stirring and condensing device, disperse 20g of ammonium polyphosphate (Type II, Hangzhou Jieersi Flame Retardant Chemical Co., Ltd., the same below) in 80ml of absolute ethanol to obtain a mixed solution, and weigh 0.65g of iso Triglycidyl cyanurate (epoxy value 0.97, Shanghai Fangruida Chemical Co., Ltd., epoxy group content 6.31×10 -3 mol) was dissolved in 10ml chloroform to obtain triglycidyl isocyanurate solution, and 3.90g epoxy resin (E-44) (epoxy value 0.44, Jiangsu Wuxi Resin Factory, epoxy group content was 0.017mol) was dissolved The epoxy resin solution was obtained in 20ml of absolute ethanol, and when the mixture was heated to 50°C, these two solutions were added to the reaction kettle in turn, kept stirring at 50°C for 30min, and then heated to 65°C, at 2 drops / s Add the curing agent solution obtained by dissolving 2.37g of modified alicyclic amine curing agent 1618 (the equivalent of active hydrogen is 113, Guangdong Xiubo Ch...

Embodiment 2

[0032] In a reactor with a stirring and condensing device, disperse 20g ammonium polyphosphate in 40ml absolute ethanol to obtain a mixed solution, weigh 0.60g triglycidyl isocyanurate (manufacturer is the same as Example 1, epoxy group The content is 5.82×10 -3mol), it was dissolved in 5ml of chloroform to obtain a triglycidyl isocyanurate solution, when the mixture was heated to 30°C, the triglycidyl isocyanurate solution was added to the reaction kettle, and the mixture was stirred and reacted at 30°C for 10 minutes. Then be warming up to 40 DEG C, drop 0.41g modified alicyclic amine curing agent 1618 (manufacturer is the same as embodiment 1, active hydrogen content is 3.63 * 10 -3 mol) was dissolved in 10ml of absolute ethanol to obtain a solidifying agent solution, kept at 40°C for 2 hours, then heated to 78°C, kept for 12 hours, cooled to room temperature, filtered with suction, and washed with distilled water and absolute ethanol respectively. ℃ vacuum drying for 8 ho...

Embodiment 3

[0034] In a reactor with a stirring and condensing device, disperse 20g ammonium polyphosphate in 60ml dehydrated alcohol to obtain a mixed solution, weigh 0.62g triglycidyl isocyanurate (manufacturer is the same as Example 1, epoxy group The content is 6.01×10 -3 mol), it is dissolved in 10ml chloroform to obtain triglycidyl isocyanurate solution, and takes by weighing 3.72g epoxy resin (E-44) (manufacturer is the same as embodiment 1, epoxy group content is 0.016mol) dissolving Obtain an epoxy resin solution in 20ml of absolute ethanol, and when the mixed solution is heated to 40°C, these two solutions are added to the reaction kettle in turn, kept stirring at 40°C for 20min, and then heated to 50°C, with 2 drops / Add dropwise the curing agent solution obtained by dissolving 2.32g of modified alicyclic amine curing agent 1618 (the manufacturer is the same as in Example 1, with an active hydrogen content of 0.021mol) in 20ml of absolute ethanol at a speed of s, and keep the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com