A flexible sensing module, manufacturing process and application thereof for dynamic monitoring of human body inductance

A technology for sensing modules and dynamic monitoring, applied in the field of sensing modules, can solve problems such as unfavorable installation and use of complex electronic equipment, poor bonding force between conductive materials and their substrates, and unstable product performance, and achieve controllable functions. , Improve the accuracy and stability, the effect of good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

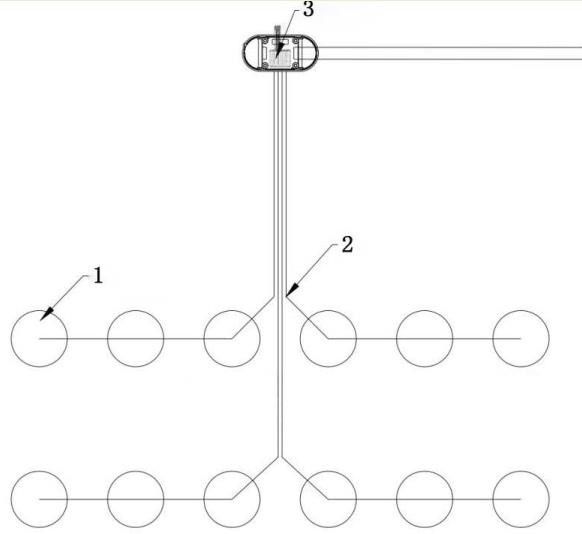

Image

Examples

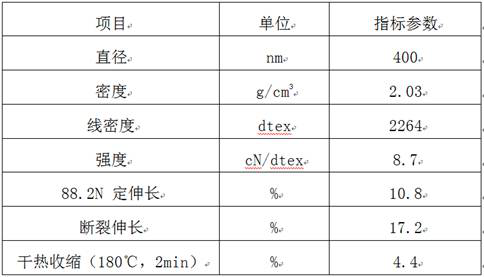

Embodiment 1

[0051] A flexible sensing module for dynamic monitoring of human body inductance and its manufacturing process. The flexible sensing module for dynamic monitoring of human body inductance is made of the following raw materials in weight percentage: 10% nano-platinum powder, 50% Fiber-grade PET chips, 8% nano-graphene, 8% epoxy resin, 2% epoxy resin reactive diluent, 2% high-efficiency dispersant and stabilizer, 10% deionized water, 10% Far-infrared fiber cloth base material.

[0052] The high-efficiency dispersant: the weight ratio of the stabilizer is 5:2.

[0053] The high-efficiency dispersant is dimethyl ethanolamine acrylate.

[0054] The stabilizer is triphenyl phosphate.

[0055] The epoxy resin is bisphenol A type epoxy resin.

[0056] The epoxy resin reactive diluent is 1,6-hexanediol diglycidyl ether.

[0057] The manufacturing process of the flexible sensing module used for dynamic monitoring of human body inductance includes:

[0058] (1) Dispersion step of fi...

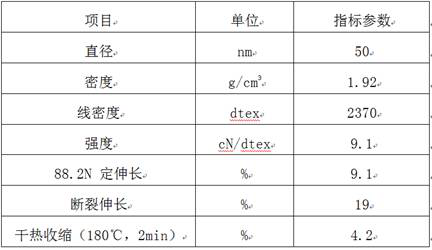

Embodiment 2

[0074] A flexible sensing module for dynamic monitoring of human body inductance and its manufacturing process. The flexible sensing module for dynamic monitoring of human body inductance is made of the following raw materials in weight percentage: 20% nano-platinum powder, 40% Fiber-grade PET chips, 8% nano-graphene, 8% epoxy resin, 2% epoxy resin reactive diluent, 2% high-efficiency dispersant and stabilizer, 10% deionized water, 10% Far-infrared fiber cloth base material.

[0075] The high-efficiency dispersant: the weight ratio of the stabilizer is 5:2.

[0076] The high-efficiency dispersant is isopropanol.

[0077] The stabilizer is triphenyl phosphate.

[0078] The epoxy resin is bisphenol A type epoxy resin.

[0079] The epoxy resin reactive diluent is 1,6-hexanediol diglycidyl ether.

[0080] The manufacturing process of the flexible sensing module used for dynamic monitoring of human body inductance includes:

[0081] (1) Dispersion step of fiber-grade PET slice...

Embodiment 3

[0097]A flexible sensing module for dynamic monitoring of human body inductance and its manufacturing process. The flexible sensing module for dynamic monitoring of human body inductance is made of the following raw materials in weight percentage: 15% nano-platinum powder, 45% Fiber-grade PET chips, 10% nano-graphene, 10% epoxy resin, 3% epoxy resin reactive diluent, 3% high-efficiency dispersant and stabilizer, 6% deionized water, 8% Far-infrared fiber cloth base material.

[0098] The high-efficiency dispersant: the weight ratio of the stabilizer is 5:2.

[0099] The high-efficiency dispersant is dimethyl ethanolamine acrylate.

[0100] The stabilizer is triphenyl phosphate.

[0101] The epoxy resin is bisphenol A type epoxy resin.

[0102] The epoxy resin reactive diluent is 1,6-hexanediol diglycidyl ether.

[0103] The manufacturing process of the flexible sensing module used for dynamic monitoring of human body inductance includes:

[0104] (1) Dispersion step of fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com