Polypropylene composition supporting laser marking and preparation method and application thereof

A polypropylene composition and laser marking technology, applied in the field of polypropylene composition, can solve the problems of high price, affect material properties, application limitations, etc., and achieve the effects of strong and durable marking, environmental friendliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

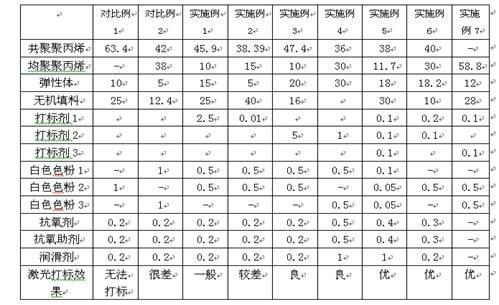

[0036] The laser markable polypropylene composition described in this embodiment has components and mass percentages as shown in Table 1:

[0037] Among them, the melt flow rate (MFR) of homopolypropylene is 10g / 10min, and the melt flow rate (MFR) of copolymerized polypropylene is 30g / 10min; the elastomer is a copolymer of ethylene-α-olefin, and its density is 0.870 g / cm 3 , the melt mass flow rate is 1.0g / 10min (2.16kg, 190°C), the carbon number of α-olefin is 4; the inorganic filler is talc powder, and the particle size is 4.7μm.

[0038] Its preparation process is as follows:

[0039]The above-mentioned components were mixed in a high-speed mixer in proportion, and the mixing and stirring time was 0.5min, and then fed through the main feeding port of the twin-screw extruder, and melted and kneaded at 200°C for 0.5min, and the length-to-diameter ratio of the screw was 32. Extruded, water-cooled, air-dried, and pelletized to 2 mm to obtain a laser-markable polypropylene com...

Embodiment 2

[0041] The composition and mass percentage of the laser-markable polypropylene composition described in this example are shown in Table 1: the melt flow rate (MFR) of the homopolypropylene is 40g / 10min, and the melt flow rate (MFR) of the copolymerized polypropylene is The melt flow rate (MFR) is 60g / 10min; the elastomer is a copolymer of ethylene-α-olefin, and its density is 0.850g / cm 3 , its melt mass flow rate is 0.5g / 10min (2.16kg, 190℃), the number of carbon atoms of α-olefin is 2; the inorganic filler is talcum powder, and the particle size is 20μm.

[0042] Its preparation process is as follows:

[0043] The above-mentioned components were mixed in a low-speed mixer in proportion, and the mixing and stirring time was 60 minutes, and then fed through the main feeding port of the reciprocating single-screw extruder, melted and mixed at 170 ° C for 5 minutes, and the screw length-to-diameter ratio was 33 , extruded, water-cooled, air-dried, and cut into 1mm pellets to obt...

Embodiment 3

[0045] The composition and mass percentage of the laser-markable polypropylene composition described in this example are shown in Table 1: the melt flow rate (MFR) of the homopolypropylene is 60g / 10min, and the melt flow rate (MFR) of the copolymerized polypropylene is The melt flow rate (MFR) is 10g / 10min; the elastomer is a copolymer of ethylene-α-olefin, and its density is 0.930g / cm 3 , the melt mass flow rate is 0.2g / 10min (2.16kg, 190°C), the carbon number of α-olefin is 10; the inorganic filler is talcum powder, and the particle size is 10μm.

[0046] Its preparation process is as follows:

[0047] The above-mentioned components were mixed in an internal mixer in proportion, and the mixing and stirring time was 15 minutes, and then fed through the main feeding port of the reciprocating single-screw extruder, and melted and mixed for 1 minute at 240 ° C. The length-to-diameter ratio of the screw was 33. Extruded, water-cooled, air-dried, and pelletized to 3mm to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com