Nanometer modified asphalt micro-emulsion and preparation method thereof

A technology of modified asphalt and microemulsion, applied in building components, building insulation materials, buildings, etc., can solve the problems of storage stability, poor temperature resistance stability, thermodynamic instability, delamination, etc., and achieve easy operation and good storage Stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

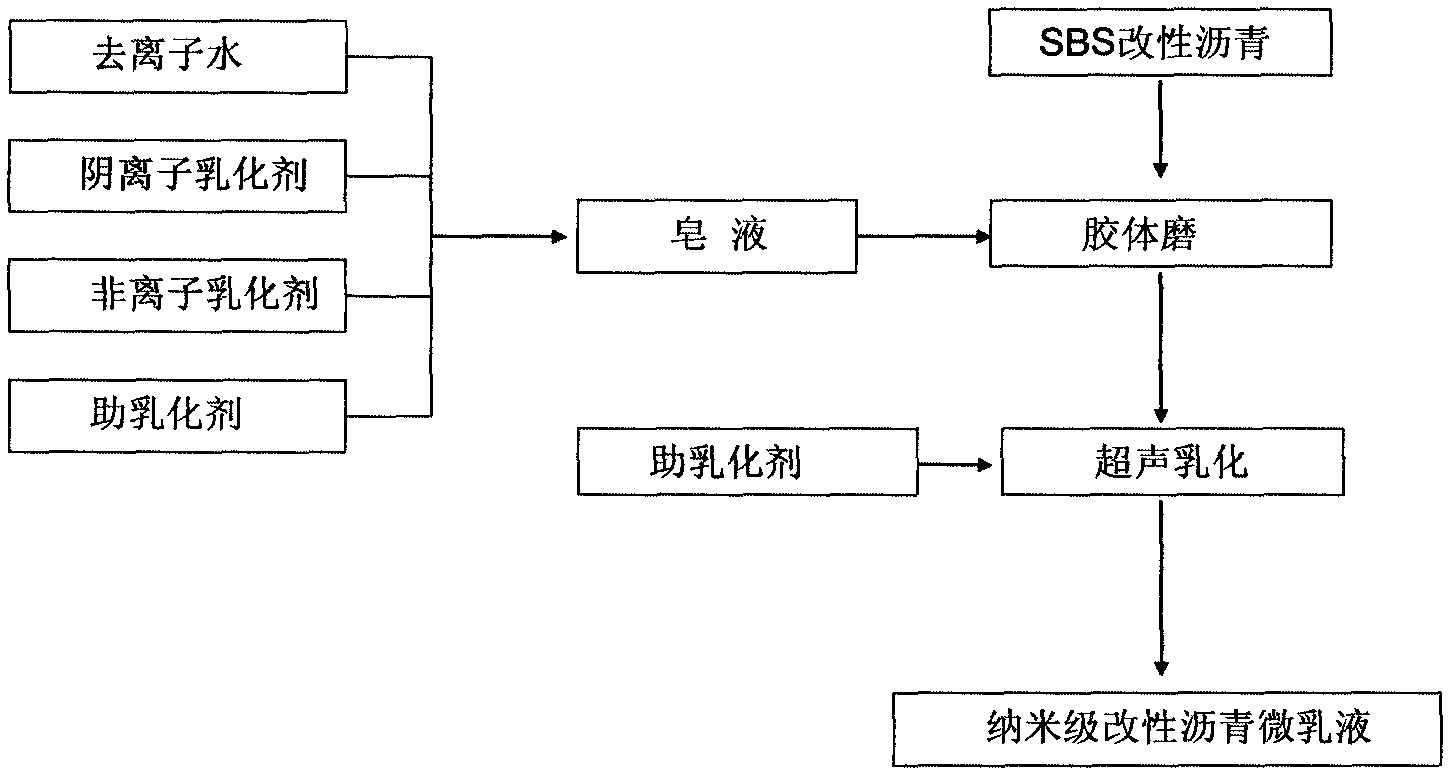

[0025] A preparation method of nano-scale modified asphalt microemulsion is carried out as follows,

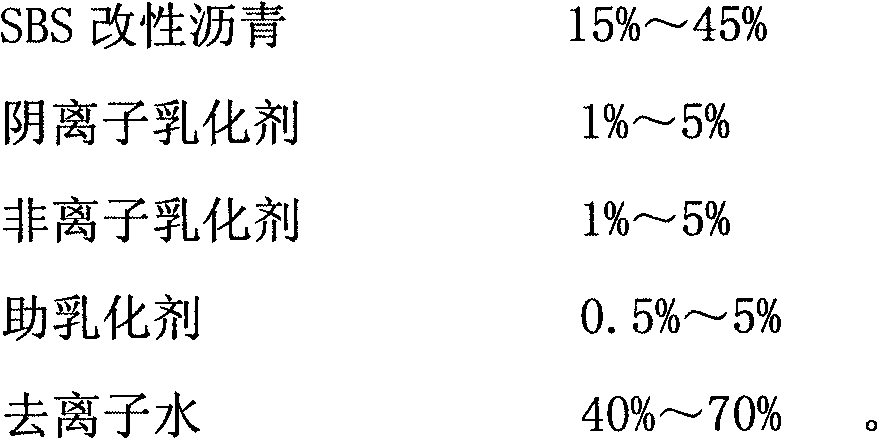

[0026] A. Mix 1%~5% anionic emulsifier and 1%~5% nonionic emulsifier to form a synergistic effect of emulsifier compounding. At the same time, add 40%~70% deionized water, and then add 0.25%~2.5% It has a co-emulsifier that can further reduce the interfacial tension, and is heated to 40-65 ° C, and prepared into a soap liquid under the action of stirring and shearing force. Wherein, when forming uniform transparent soap liquid, stirring and shearing stop, and stirring shear speed is advisable with soap liquid not splashing out;

[0027] B Heat 15%-45% SBS modified asphalt to 110-165°C;

[0028] C. Transport the soap solution prepared in step A and the SBS modified asphalt after heat treatment in step B to the colloid mill for pre-emulsification for 10-30 minutes to obtain a pre-emulsion with certain stability. The colloid mill speed is 8000r / min~ 11000r / min, the control pres...

Embodiment 1

[0032] Adopt 3g sodium dodecylsulfonate anionic emulsifier and 1g nonylphenol polyoxyethylene ether nonionic emulsifier compound, be dissolved in 70g deionized water together, then add 2g n-butanol, with stirring and shearing Method Prepare soap liquid and heat it to 65°C; heat 30g of SBS modified asphalt to 120°C; send the soap liquid and heated SBS modified asphalt to the colloid mill at the same time for pre-emulsification for 10min. The speed of the colloid mill is 10000r / min, and the control pressure of the colloid mill is 0.3MPa. When the temperature of the pre-emulsion drops below 70°C, the pre-emulsion is further emulsified by ultrasonic equipment for 10 minutes, wherein the ultrasonic power is adjusted to 500w, and the frequency is 9 ×10 4 Hz. At the same time, 2 g of n-butanol was added and ultrasonic emulsification was continued for 15 minutes to obtain a nanoscale modified asphalt microemulsion.

Embodiment 2

[0034] Adopt 5g sodium dodecylsulfonate anionic emulsifier and 2g nonylphenol polyoxyethylene ether nonionic emulsifier compound, be dissolved in 150g deionized water together, then add 4g n-butanol, with stirring and shearing Method Prepare soap liquid and heat it to 65°C; heat 50g of SBS modified asphalt to 120°C; send the soap liquid and heated SBS modified asphalt to the colloid mill for pre-emulsification for 10min at the same time. The speed of the colloid mill is 10000r / min, and the control pressure of the colloid mill is 0.3MPa. When the temperature of the pre-emulsion drops below 70°C, the pre-emulsion is further emulsified by ultrasonic equipment for 10 minutes, wherein the ultrasonic power is adjusted to 500w, and the frequency is 9 ×10 4 Hz. At the same time, 2 g of n-butanol was added and ultrasonic emulsification was continued for 15 minutes to obtain a nanoscale modified asphalt microemulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com