Aqueous printing ink for nonstick coat of cooking appliance

A technology for cooking utensils and non-stick coating, applied in inks, home utensils, applications, etc., can solve problems such as easy clogging of mesh holes, and achieve good steam resistance, health protection, and good interlayer adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

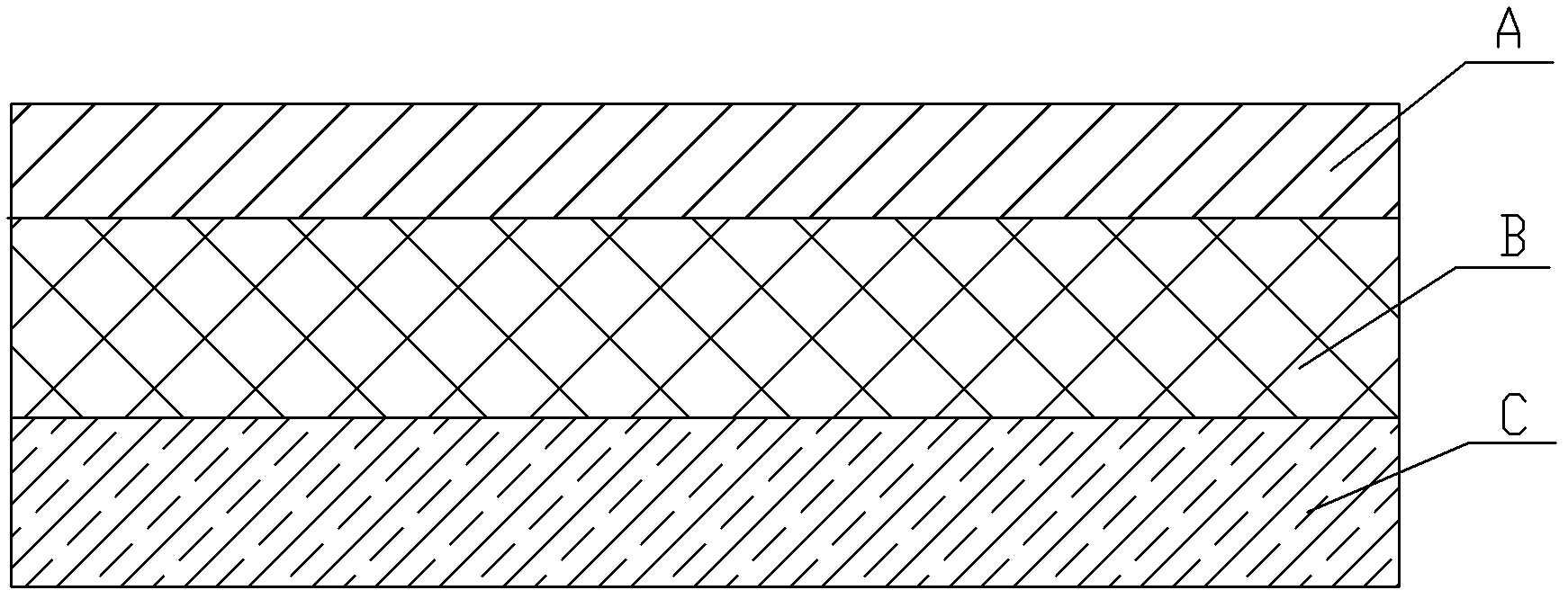

Image

Examples

Embodiment 1

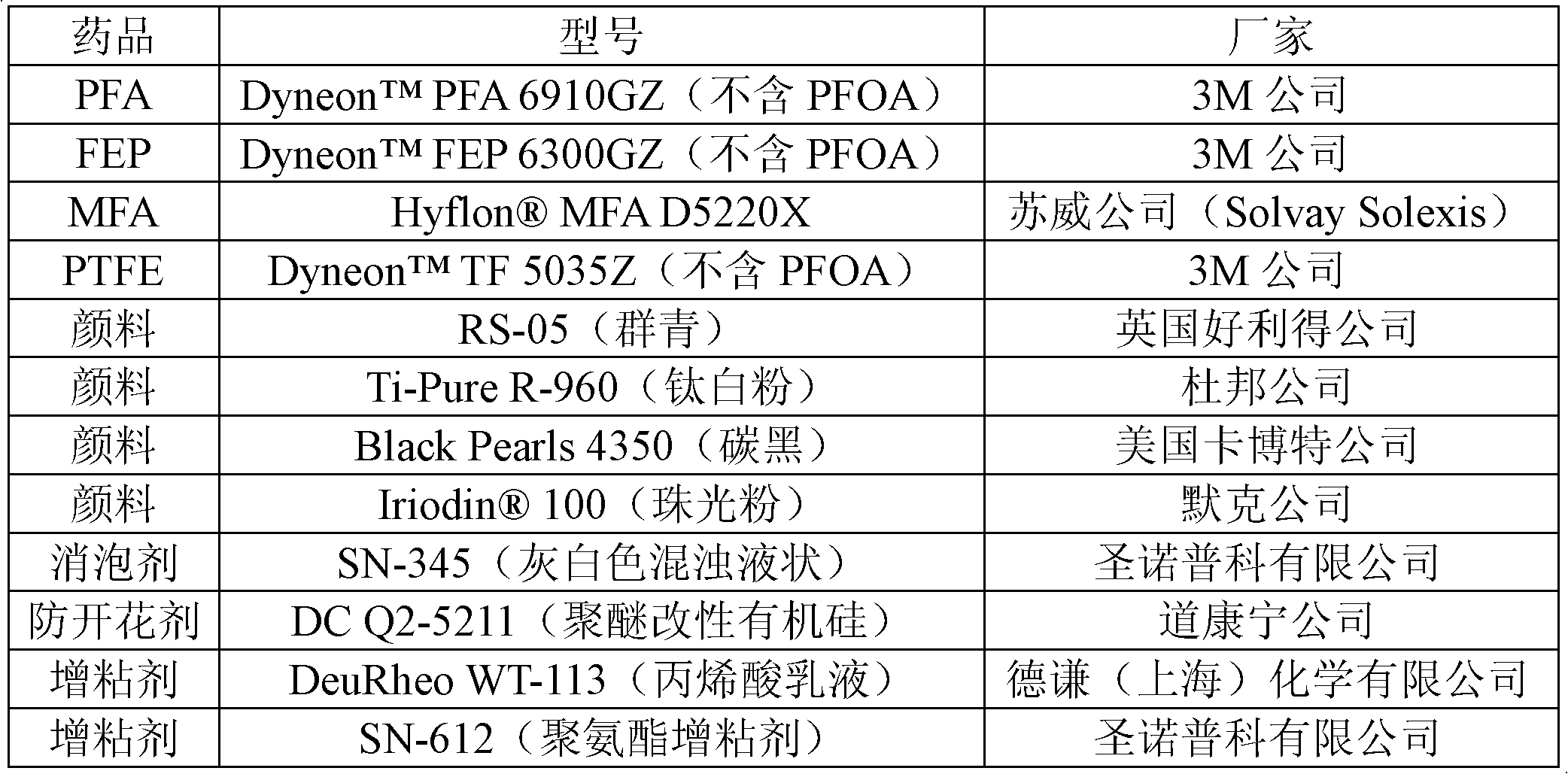

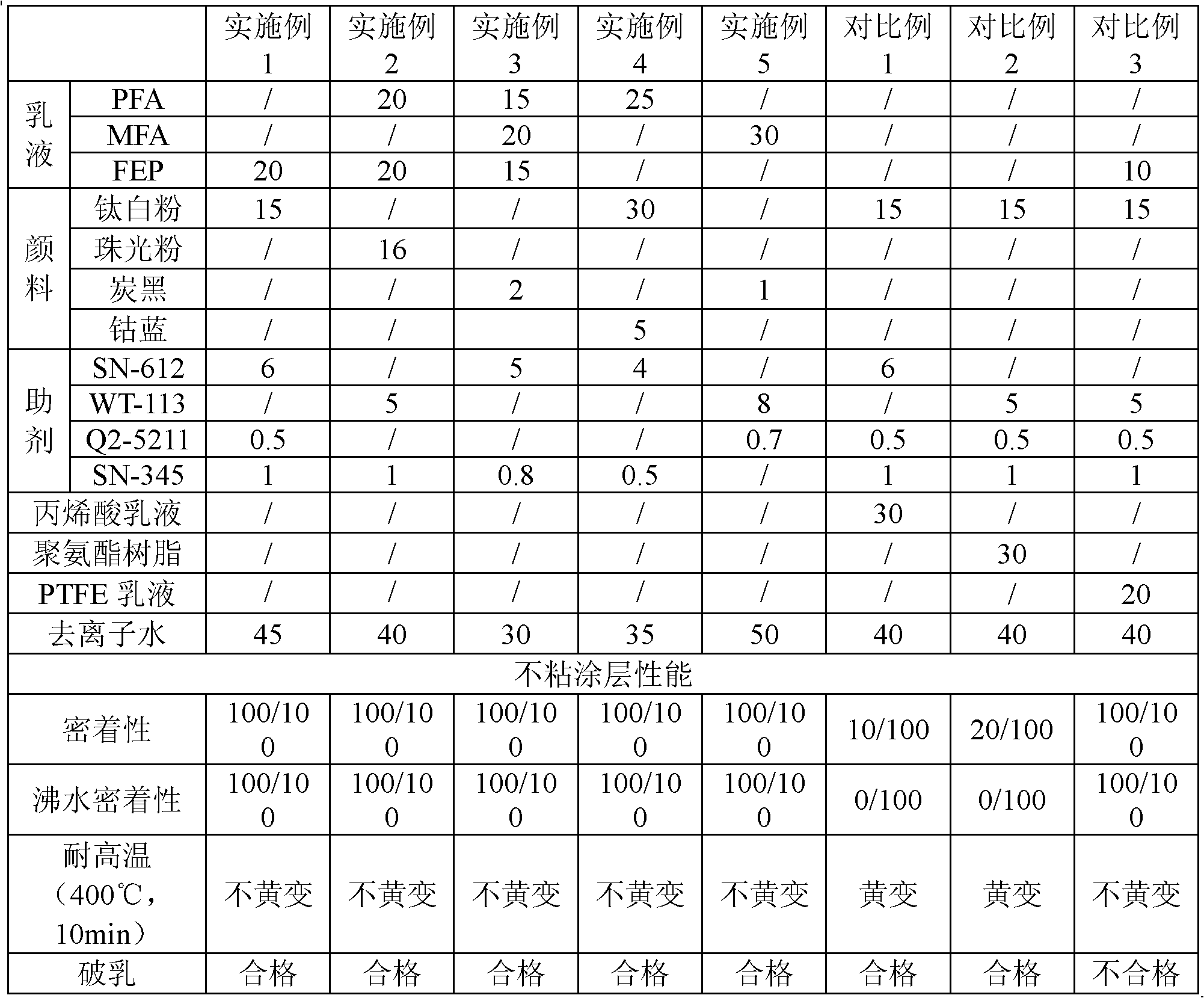

[0035]Embodiment one: a kind of water-based ink that is used for non-stick coating of cooking utensils, adopts following process preparation:

[0036] Mix 15g of titanium dioxide R-960 with 45g of deionized water and grind it with a three-roller mill, then add 20g of FEP 6300GZ emulsion, 1g of defoamer SN-345, and 0.5g of anti-flowering The thickening agent SN-612 of agent Q2-5211 and 6g, stirs evenly, promptly obtains described water-based ink.

Embodiment 2

[0037] Embodiment two: a kind of water-based ink that is used for non-stick coating of cooking utensils, adopts following process preparation:

[0038] 16g of pearl powder Mix 100 with 40g of deionized water evenly, add 20g of FEP 6300GZ emulsion, 20g of PFA 6910GZ emulsion, 1g of defoamer SN-345 and 5g of tackifier WT-113 under continuous stirring, and stir evenly, that is Obtain described water-based ink.

Embodiment 3

[0039] Embodiment three: a kind of water-based ink for non-stick coating of cooking utensils is prepared by the following process:

[0040] Mix 2g of carbon black Black Pearls 4350 with 30g of deionized water and grind it with a three-roll mill, then add 15g of PFA 6910GZ emulsion, 20g of MFA D5010X emulsion, 15g of FEP 6300GZ emulsion, 0.8g of The antifoaming agent SN-345 and the tackifier SN-612 of 5g, stir evenly, promptly obtain described water-based ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com