Waste oil regeneration system

A technology of waste oil regeneration and settling tank, which is applied in the direction of filtration and separation, only multi-stage series refining process treatment, filtration circuit, etc., and can solve the problems such as great influence on flocculation and adsorption effect, frequent replacement of filter plates, and influence on adsorption effect, etc. Achieve the effects of improving regeneration and purification efficiency, ensuring standardized operation, and restoring color and indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

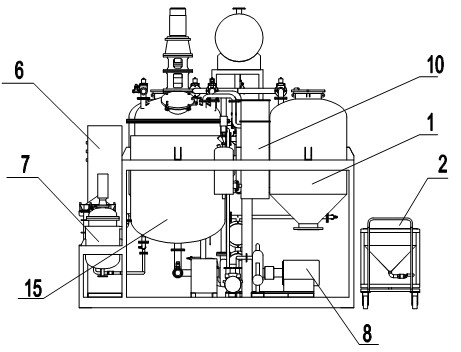

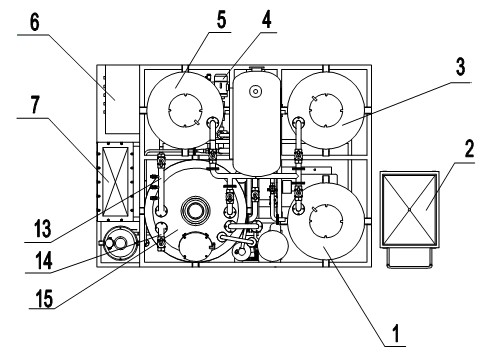

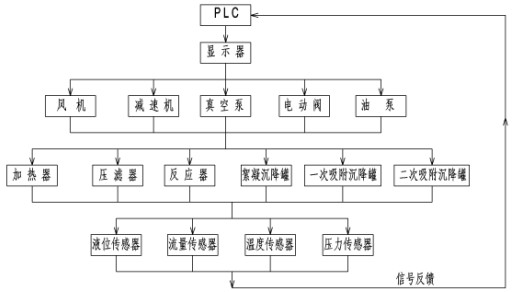

[0026] like figure 1 , figure 2 As shown, a waste oil regeneration system of the present invention includes a reactor 15 and a filter press 4. The upper end of the reactor 15 is provided with a coagulant and waste oil common inlet 13, an adsorbent powder feed port 14, and a flocculation settling tank 1. The first adsorption settling tank 3, the second adsorption settling tank 5, the flocculation settling tank 1, the first adsorption settling tank 3, and the second adsorption settling tank 5 are respectively connected to the reactor 15 through the processing pipeline, and the processing pipeline There is a valve in the middle; the bottom of the reactor 15 is provided with a mortar pump 8, and the mortar pump 8 can pump the material in the reactor 15 out to the flocculation settling tank 1 and the first adsorption settling tank 3 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com