Method for producing sodium alginate lyase by utilizing vibrio vulnificus

A technology for producing algin and marine vibrio by Vibrio, which can be applied in the field of bioengineering and can solve problems such as low enzyme production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

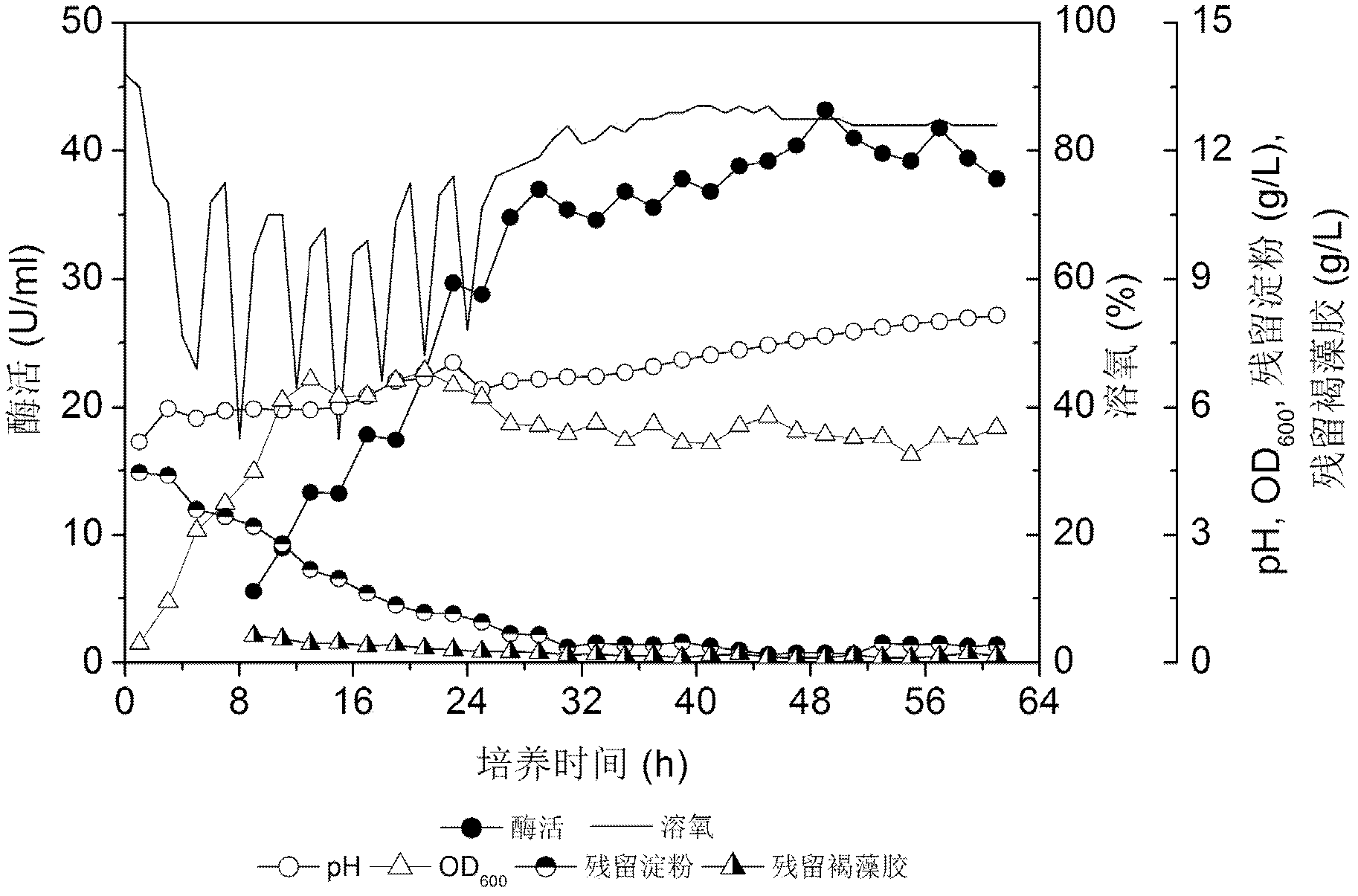

[0059] Embodiment 1, the fed-batch fermentation of adding 3g of solid alginate every 3h during the fermentation process

[0060] 1. Bioreactor

[0061] The fermenter used in the following examples is the FMG-5L fermenter produced by Shanghai Guoqiang Biochemical Engineering Equipment Co., Ltd.

[0062] 2. Culture medium preparation

[0063] Weigh 15g of soluble starch, gelatinize with part of deionized water; weigh 14.1g of peptone, 6g of yeast extract, 5.1g of potassium dihydrogen phosphate, 0.3g of magnesium sulfate heptahydrate, 126g of sodium chloride, and use part of deionized water Dissolve; mix the two to 3L; adjust the pH of the fermentation broth to 5.0 with hydrochloric acid after filling the tank.

[0064] Weigh 18g of solid alginate and divide it into 6 portions, put 3g in each portion into a 50ml centrifuge tube; sterilize.

[0065] 3. Fermentation culture

[0066] Marine Vibrio sp.QY102 was provided by Ocean University of China.

[0067] Pick a single colony...

Embodiment 2

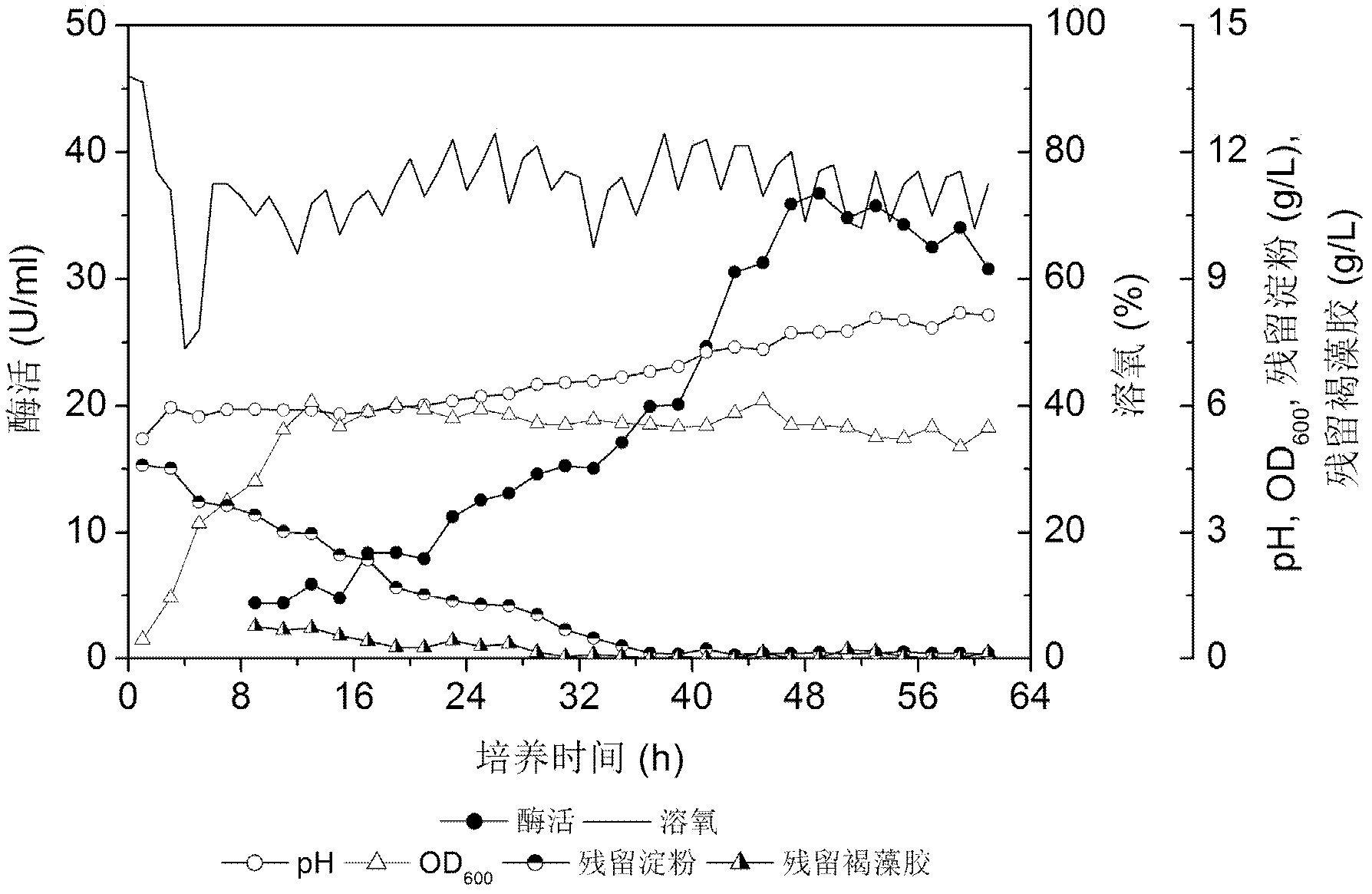

[0069] Example 2, fed-batch fermentation in which 1 g of solid alginate is added every 3 hours during the fermentation process

[0070] 1. Bioreactor

[0071] Same as "1" in Example 1.

[0072] 2. Culture medium preparation

[0073] The medium preparation is the same as "2" in Example 1.

[0074] Weigh 18g of solid alginate and divide it into 18 portions, put 1g of each portion into a 50ml centrifuge tube; sterilize.

[0075] 3. Fermentation culture

[0076] Same as "3" in Example 1. The difference is that: starting from the first addition of solid alginate, add it every 3 hours, add 1g each time, and add 18 times of 18g alginate in total.

[0077] Under this process, the fermentation ended in 61 hours, and the highest enzyme activity was 36.74U / ml in 49 hours during the fermentation process. For the fermentation process curve, see figure 2 .

Embodiment 3

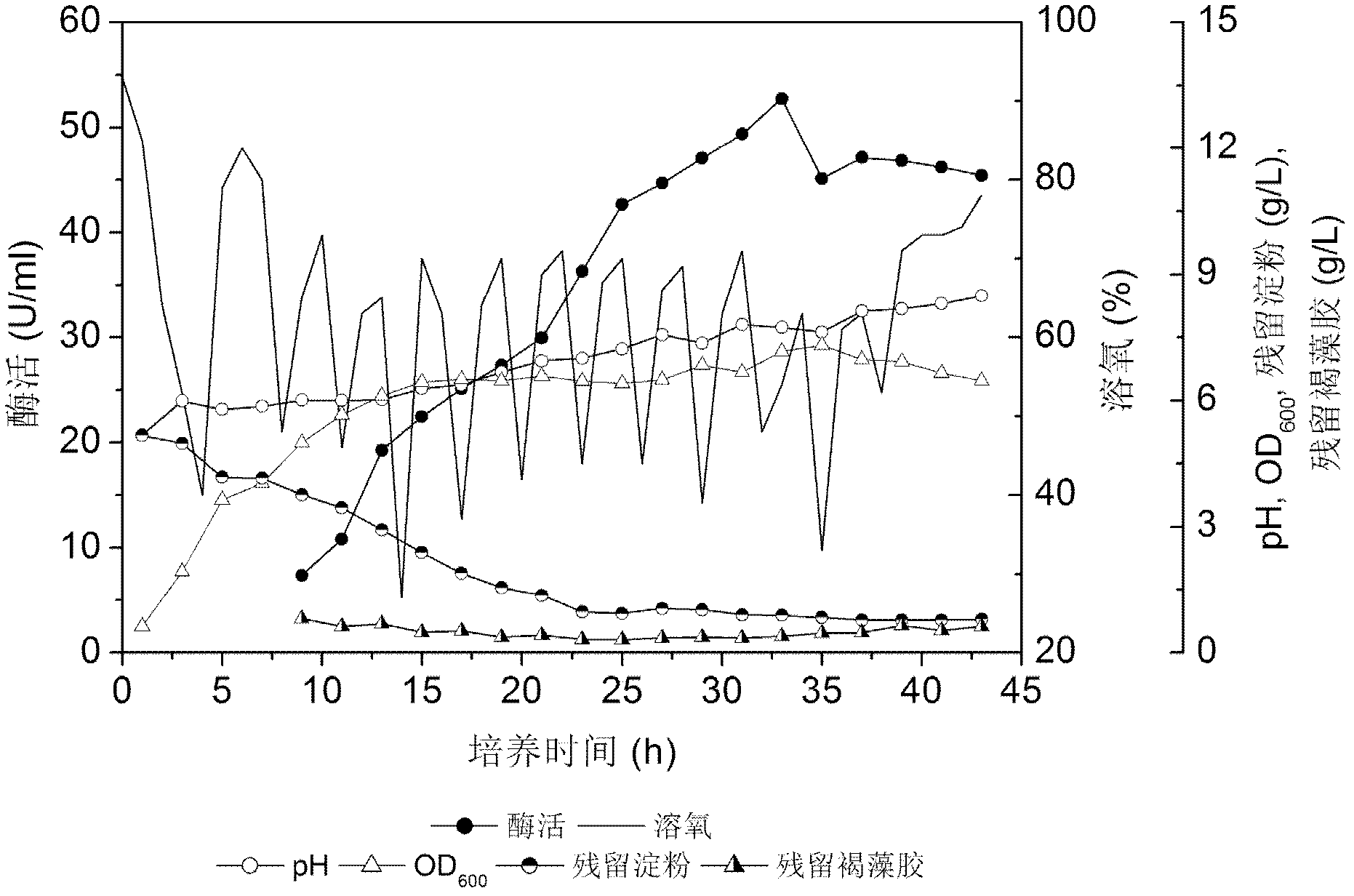

[0078] Example 3, fed-batch fermentation in which 3 g of solid alginate is added every 3 hours to the end of fermentation during the fermentation process

[0079] 1. Bioreactor

[0080] Same as "1" in Example 1.

[0081] 2. Culture medium preparation

[0082] The medium preparation is the same as "2" in Example 1.

[0083] Weigh several parts of solid alginate, put each part of 3g into a centrifuge tube; sterilize.

[0084] 3. Fermentation culture

[0085] Same as "3" in Example 1.

[0086] From the first addition of solid alginate, add 3g every 3h until the end of fermentation. Under this process, the fermentation ended in 61 hours, and the highest enzyme activity was 52.76U / ml in 33 hours during the fermentation process. For the fermentation process curve, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com