Method for immobilizing mannase by taking macroporous resin as carrier and application of immobilized mannase

A technology of mannanase and macroporous resin, applied in the direction of immobilization on/in organic carrier, fermentation, etc., can solve difficult industrial production and practical application, low efficiency of mannanase immobilization, processing technology Complicated problems, to achieve significant degradation effect, stable properties, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: AB-8 macroporous adsorption resin is used as carrier

[0029] (1) Soak the AB-8 macroporous adsorption resin with 95% ethanol for 12 hours, and stir it from time to time to make it fully swell, rinse the resin with 95% ethanol until the ethanol solution is mixed with water in a ratio of 1:5 and does not appear Until the white turbidity, finally rinse with deionized water repeatedly until the washing liquid has no ethanol smell;

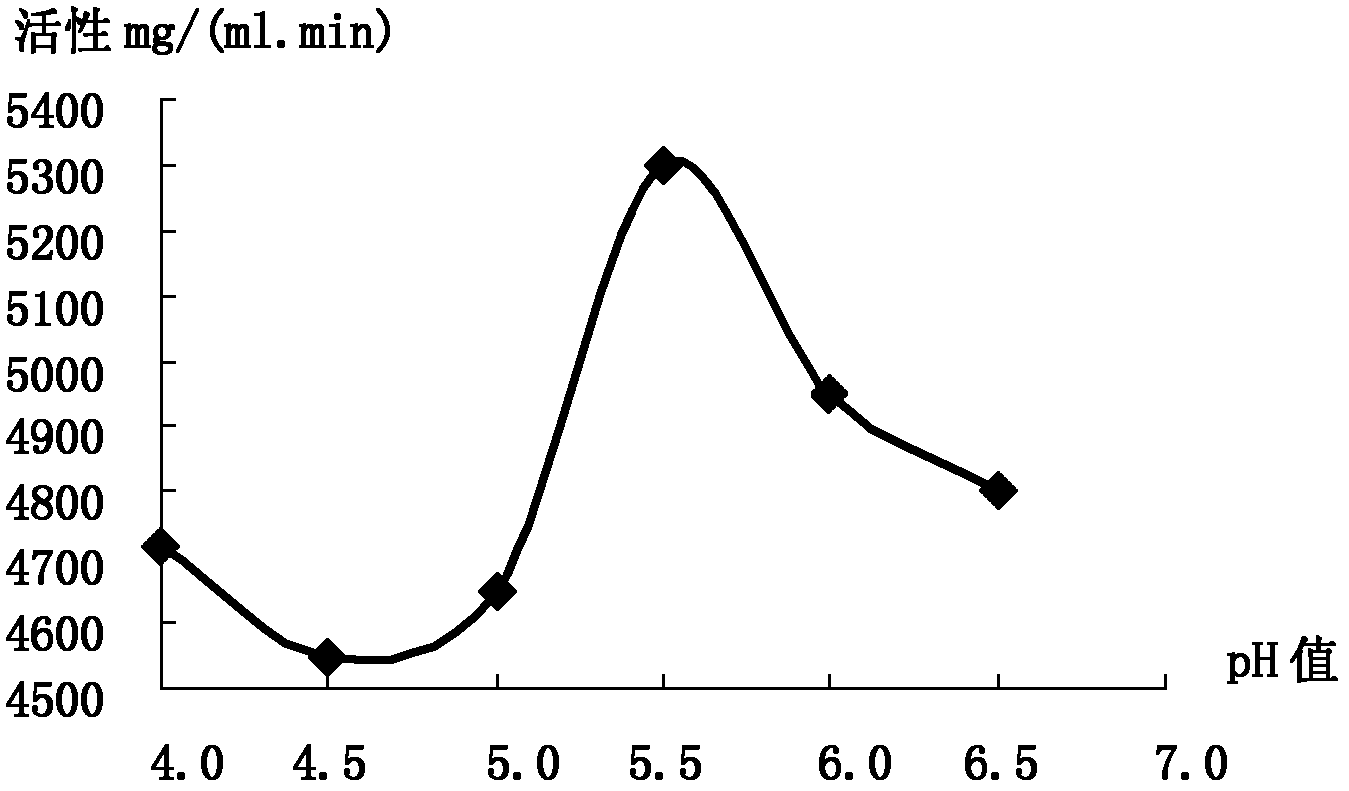

[0030] (2) Put the treated resin into 500 mL of acetic acid-sodium acetate buffer solution containing 3000 U of mannanase, the pH value of the buffer solution is 5.5, and keep the temperature at 45° C. for 8 hours for oscillating adsorption.

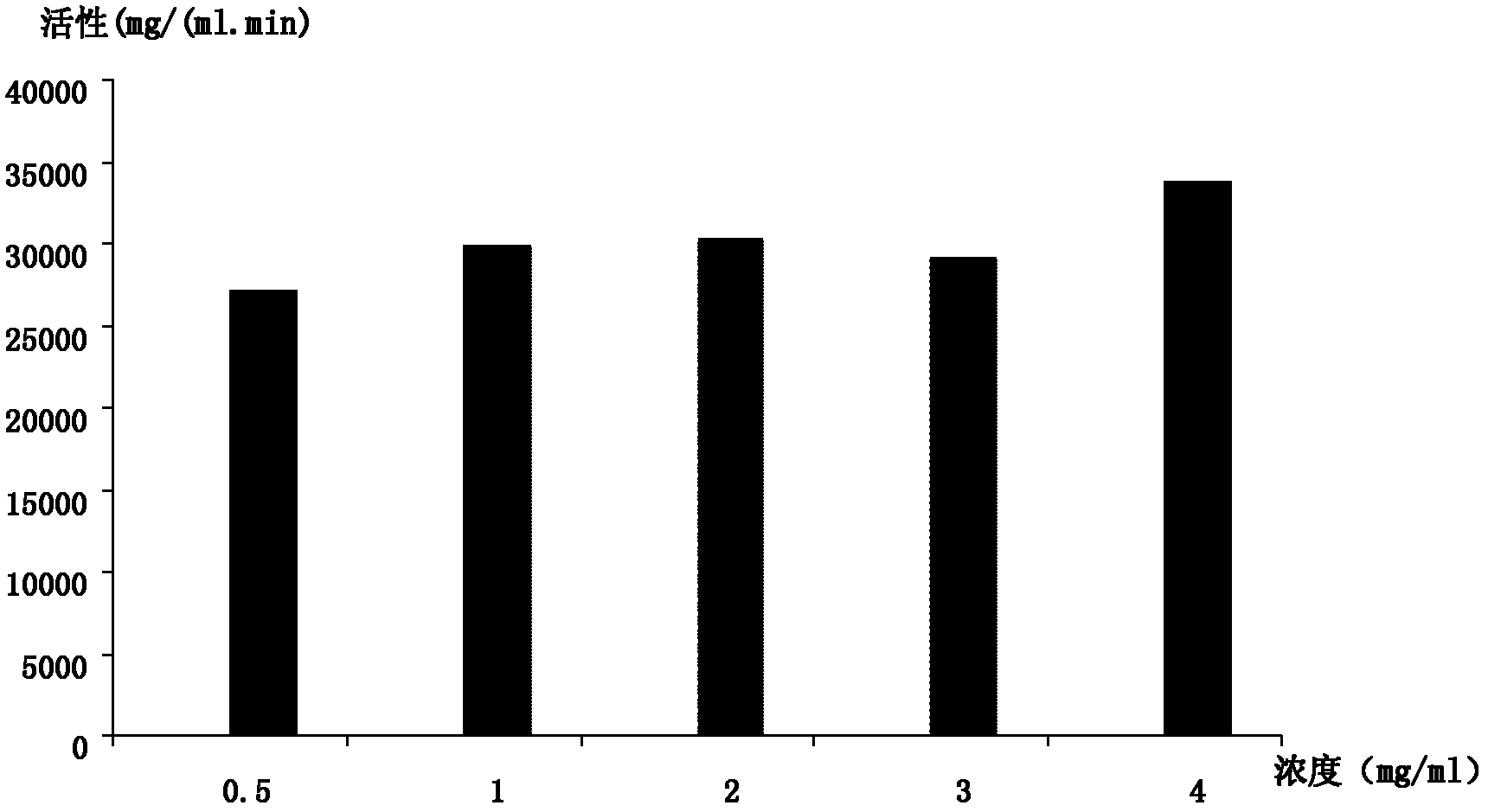

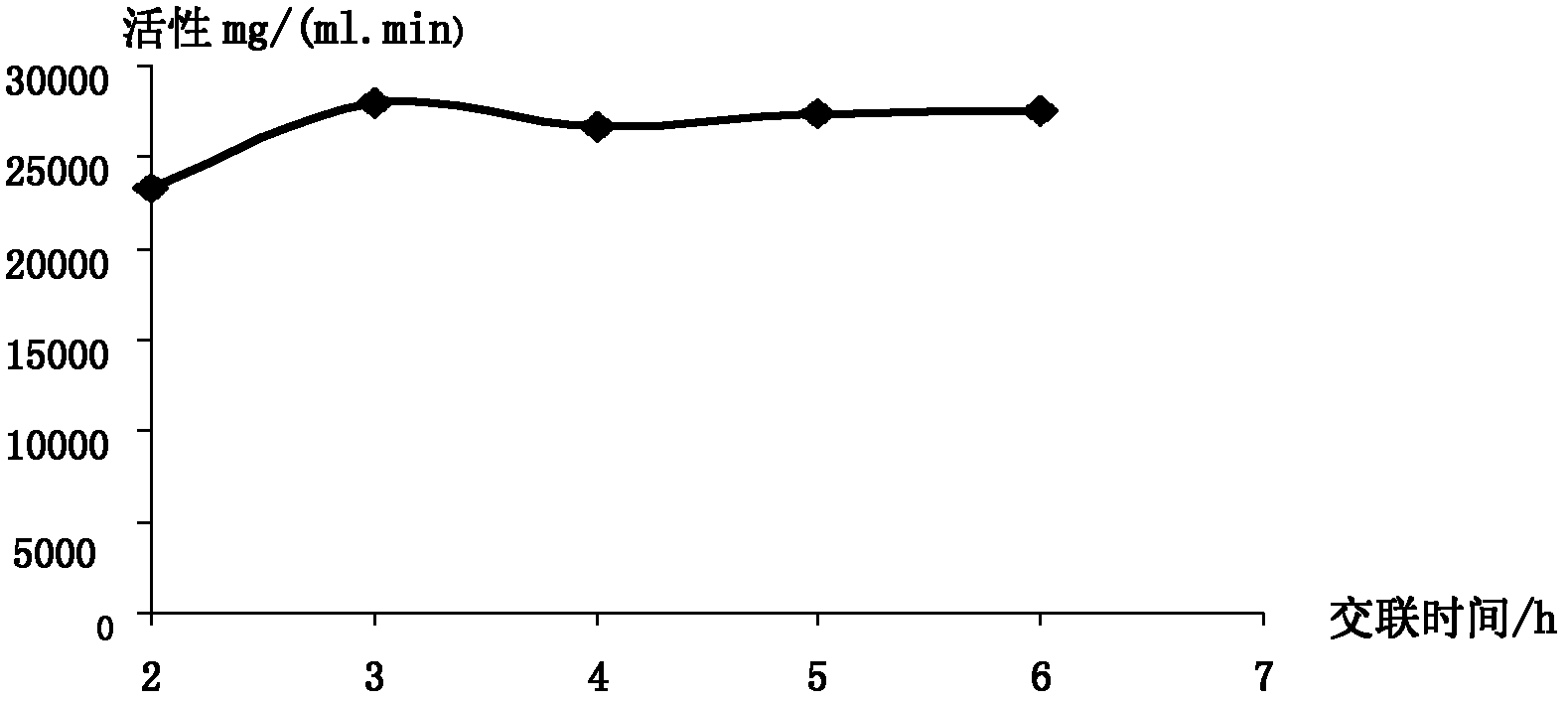

[0031] (3) Using glutaraldehyde with a mass concentration of 4%, oscillating and cross-linking for 3 hours, vacuum filtration to obtain immobilized mannanase, and storing in a refrigerator at 4°C for later use.

Embodiment 2

[0032] Embodiment 2: X-5 macroporous adsorption resin is made carrier

[0033] (1) Soak X-5 macroporous adsorption resin with ethanol overnight, wash with distilled water for several times, then soak in distilled water for several times until neutral, soak in distilled water for several times until neutral, soak more than double the volume of distilled water and place in a 4°C refrigerator spare.

[0034] (2) Put the treated resin into 500 mL of acetic acid-sodium acetate buffer solution containing 3000 U of mannanase, the pH value of the buffer solution is 5.5, and keep the temperature at 45° C. for 8 hours for oscillating adsorption.

[0035] (3) Using glutaraldehyde with a mass concentration of 4%, oscillating and crosslinking for 3 hours, collecting the filter cake by vacuum filtration, obtaining immobilized mannanase by vacuum filtration, and storing it in a refrigerator at 4°C for later use.

Embodiment 3

[0036] Embodiment 3: D-151, D-152 cation exchange resin carrier

[0037] (1) Take a certain amount of D-151 and D-152 cation exchange resins and soak them in distilled water to swell and remove impurities, then treat them with 0.1mol / L HCl for 1 hour, wash them with distilled water until they are neutral, and then treat them with 0.1mol / L NaOH After 1 hour, wash with distilled water until neutral, blot dry, and store in a 4°C refrigerator for later use.

[0038] (2) Put the treated resin into 500 mL of acetic acid-sodium acetate buffer solution containing 3000 U of mannanase, the pH value of the buffer solution is 5.5, and keep the temperature at 45° C. for 8 hours for oscillating adsorption.

[0039] (3) Using glutaraldehyde with a mass concentration of 4%, oscillating and crosslinking for 3 hours, collecting the filter cake by vacuum filtration, obtaining immobilized mannanase by vacuum filtration, and storing it in a refrigerator at 4°C for later use.

[0040] The immobili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com