Corrosion inhibitor and preparation and application thereof

A technology of corrosion inhibitors and corrosion inhibitors, which is applied in the field of adding corrosion inhibitors, can solve the problems of unstable film-forming performance, poor solubility, good film-forming performance of corrosion inhibitors, etc., and achieve good dispersibility and solubility, Simple synthesis process and high corrosion inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0040] Embodiment 1~3 prepares component (A)

Embodiment 12

[0041] Example 1

Embodiment 1~3

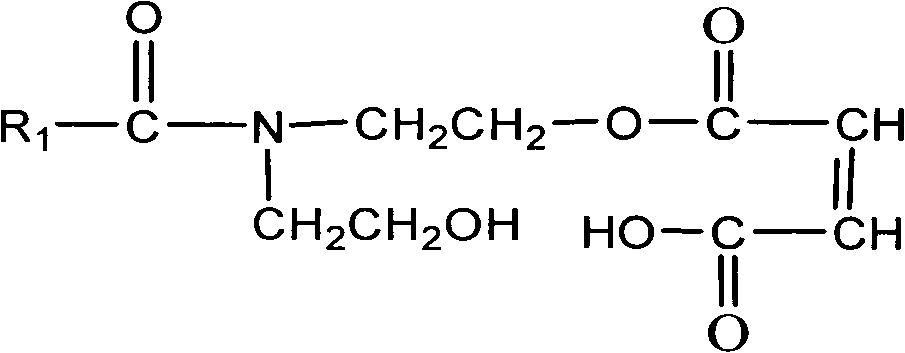

[0042] Put oleic acid and diethanolamine into the reactor at a molar ratio of 1:2, raise the temperature to 140-220°C under constant stirring, and feed in N 2 Gas, reflux for 3-6 hours, reduce the reaction temperature to 70-120 °C, and add 1:2 diethanolamine, and add 0.5% NaOH, control the reaction progress with the acid value, obtain the fatty acid amide intermediate, and continue the reaction After the reaction is completed, cool the intermediate to below 50°C for 3 to 6 hours, slowly add maleic anhydride in batches according to the molar ratio of 1:1.1, and react at 70 to 110°C for 3 to 8 hours after the addition, and obtain Oleamide maleate (A) 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com