Suede-making additive for low-reflectivity monocrystalline silicon

A monocrystalline silicon texturing and low reflectivity technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high power generation cost and lack of competitiveness, so as to reduce surface reflectivity and improve photoelectricity. The effect of conversion efficiency and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

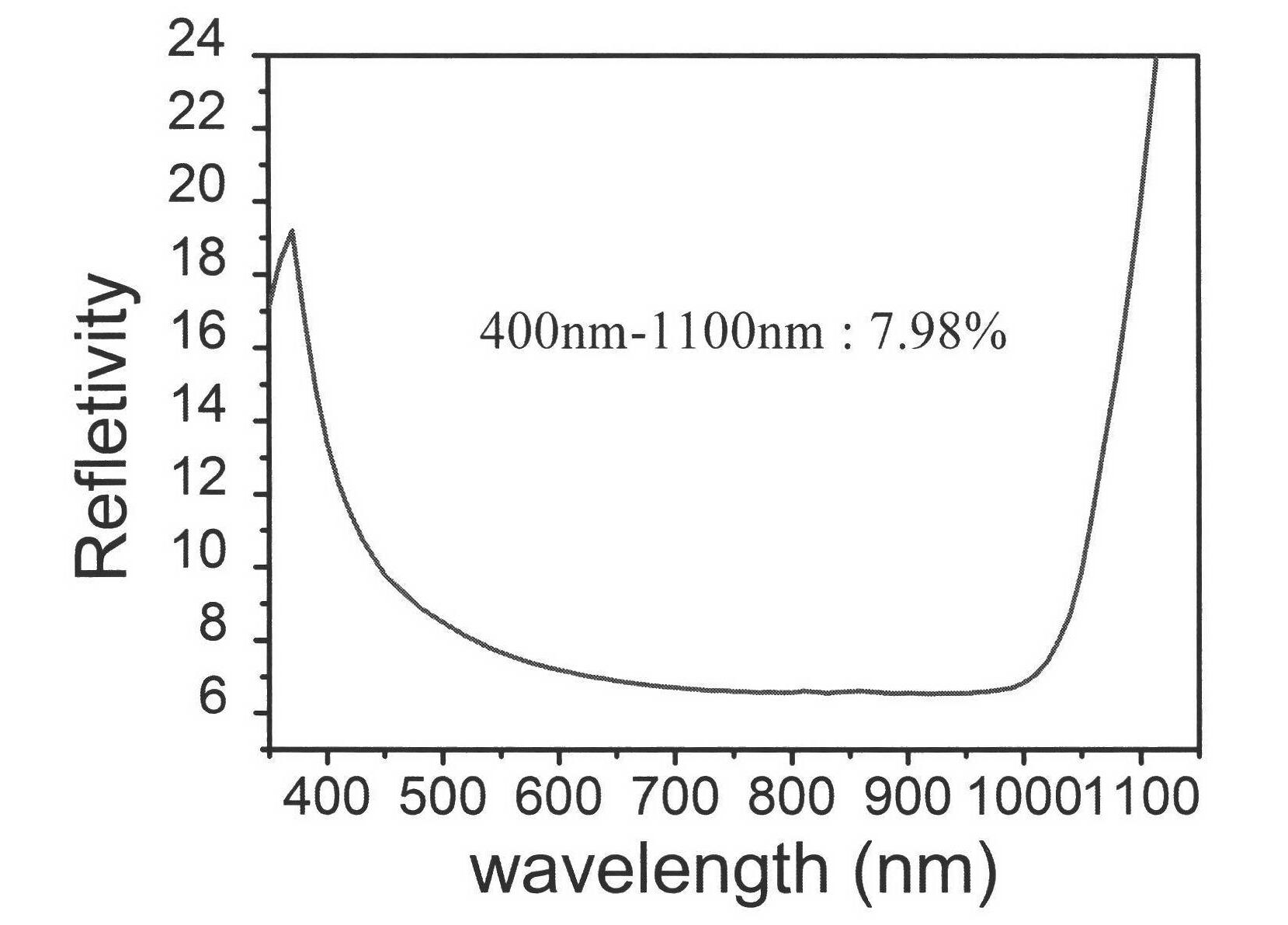

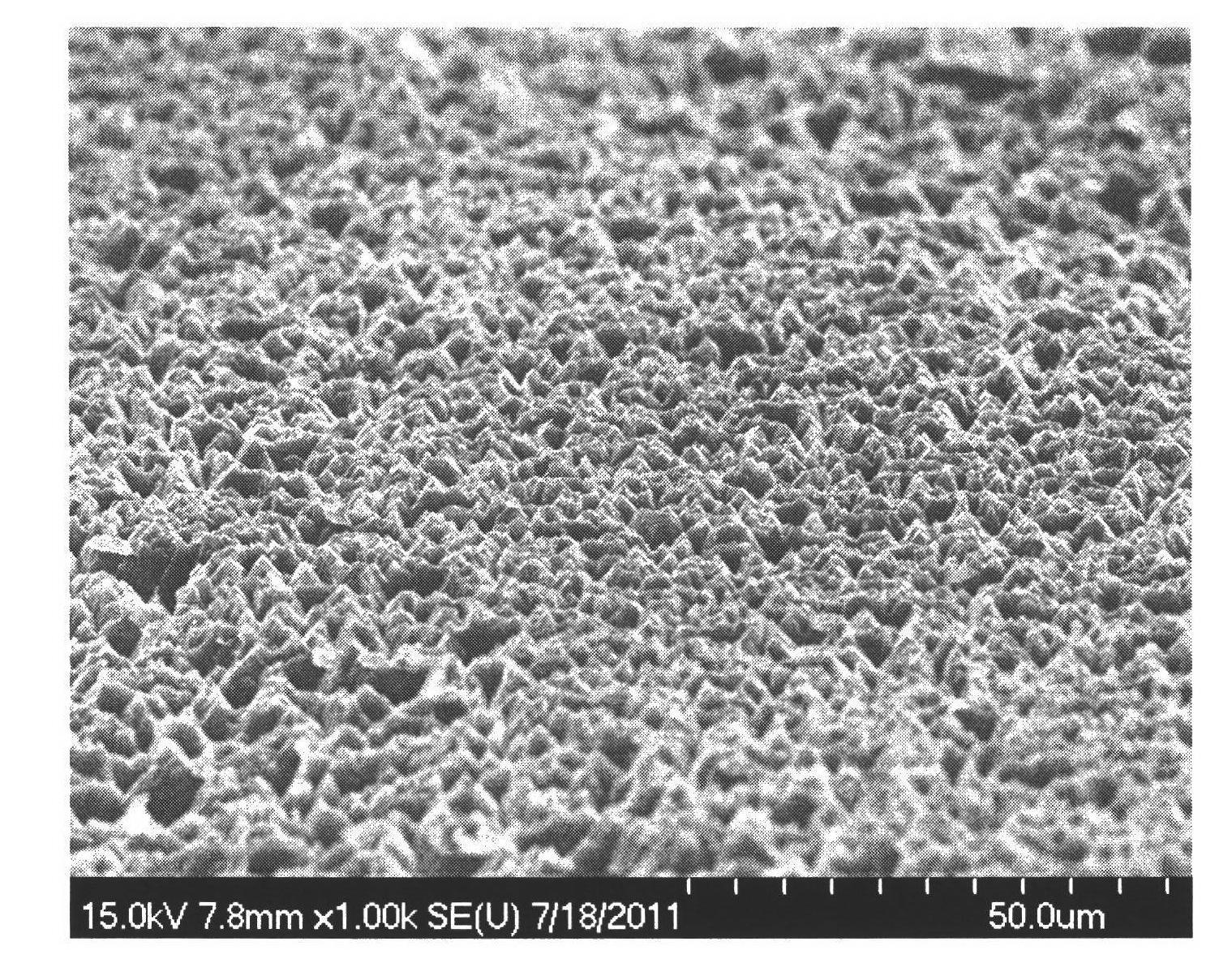

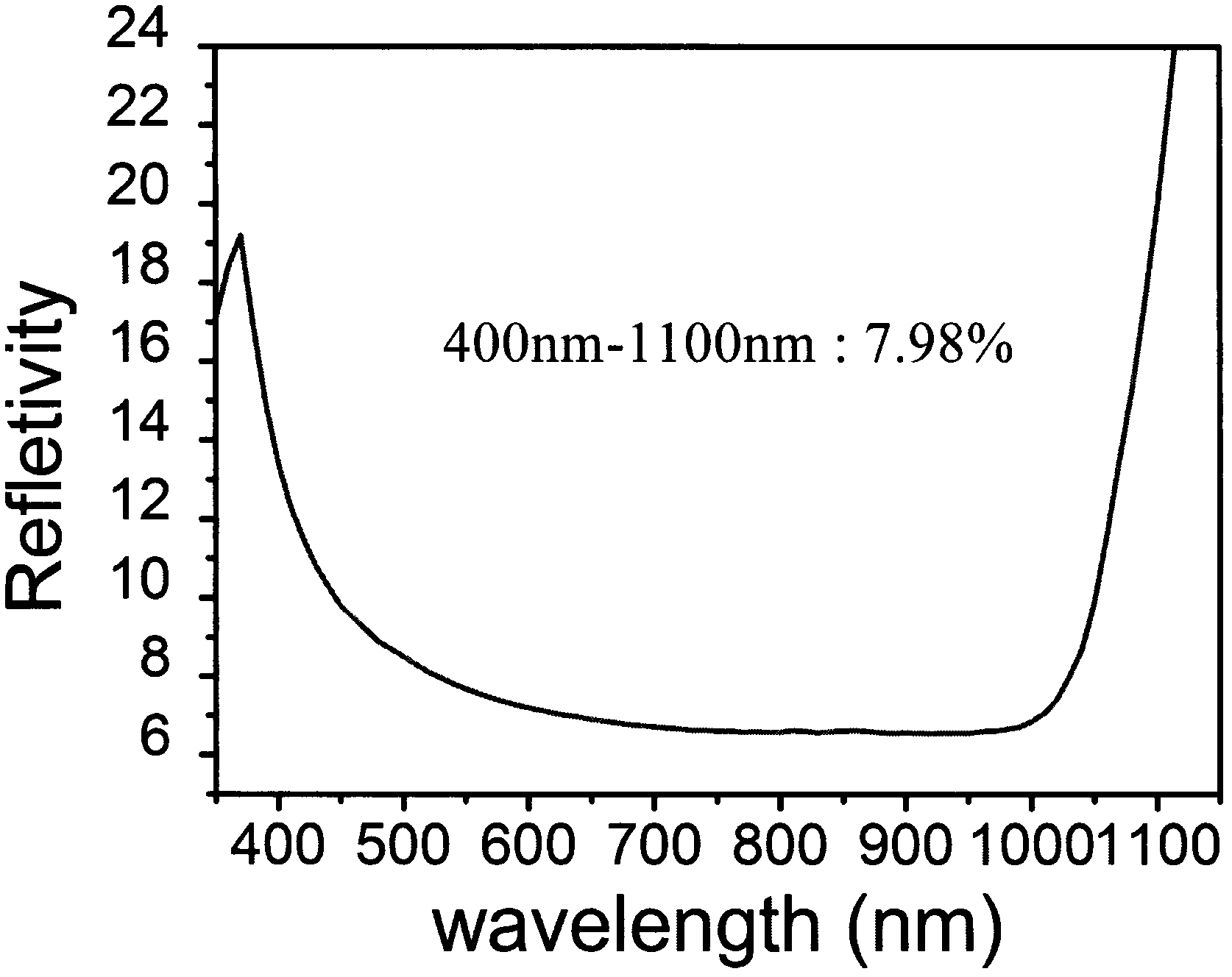

[0018] This specific embodiment adopts the following technical scheme: the formula component of low reflectivity monocrystalline silicon texturing additive is sodium tripolyphosphate, sodium butylnaphthalene sulfonate and deionized water, and it is applied to the suede surface of monocrystalline silicon wafer During fabrication, the average value of the surface reflectance of the single crystal silicon wafer within the wavelength range of 400nm-1100nm can be reduced from about 10% at present to less than 8%.

[0019] The concrete example of this embodiment is as follows:

[0020] Example 1. Sodium tripolyphosphate, sodium butylnaphthalene sulfonate and deionized water are mixed with low-reflectivity monocrystalline silicon texturing additives. The concentration of sodium tripolyphosphate is 8wt%, and the concentration of sodium butylnaphthalenesulfonate is 2wt%. . Then the monocrystalline silicon texturing additive with low reflectivity is added to the aqueous solution of sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com