Comprehensive test system for automobile instruments

A technology for automotive instrumentation and comprehensive testing, applied in the direction of instruments, etc., can solve the problems of low signal accuracy, low versatility of equipment and testing process, unsatisfactory results, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

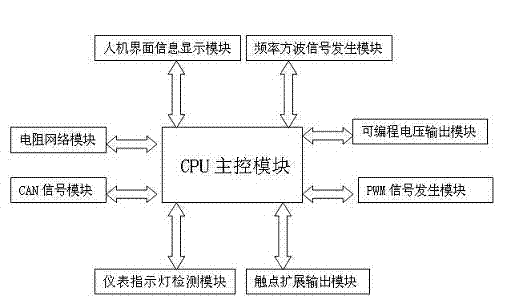

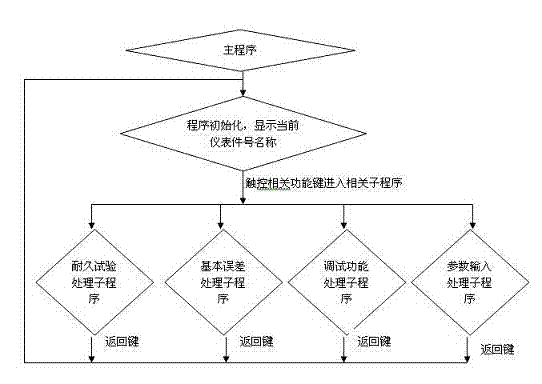

Method used

Image

Examples

Embodiment 1

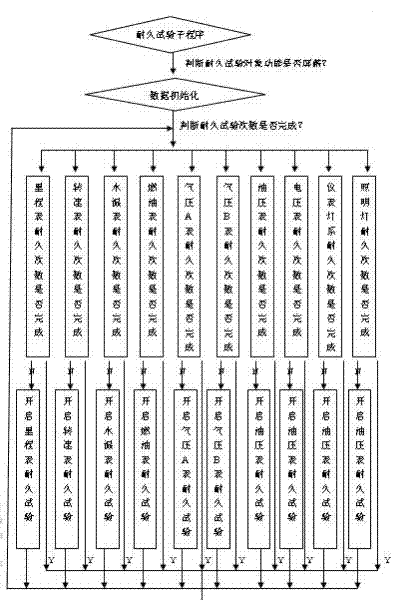

[0061] The specific example of this implementation is: the durability test of the 08 light truck full electronic instrument (part number: 58QN), the durability test includes: the odometer, the speedometer, the water temperature gauge, the fuel gauge, the air pressure gauge A, the air pressure gauge B, and the sky blue standard 7 small meters; carry out two states of full bright and full dark for each indicator light and light on the instrument panel, and carry out durability tests for different times respectively. The process is as follows:

[0062] ① Call out the part number code of the instrument assembly from the control system, and the system will automatically load all the test parameters of the meter into the data buffer.

[0063] ② To modify the test parameters and related parameters, please click the "Parameter Input" button to enter the parameter input subroutine interface. For example, the odometer, tachometer, water temperature gauge, fuel gauge, sky blue gauge, ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com