Transfer method of large area graphene

A transfer method, graphene technology, applied in coating, gaseous chemical plating, metal material coating process and other directions, to achieve the effect of simple method, saving production cost and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

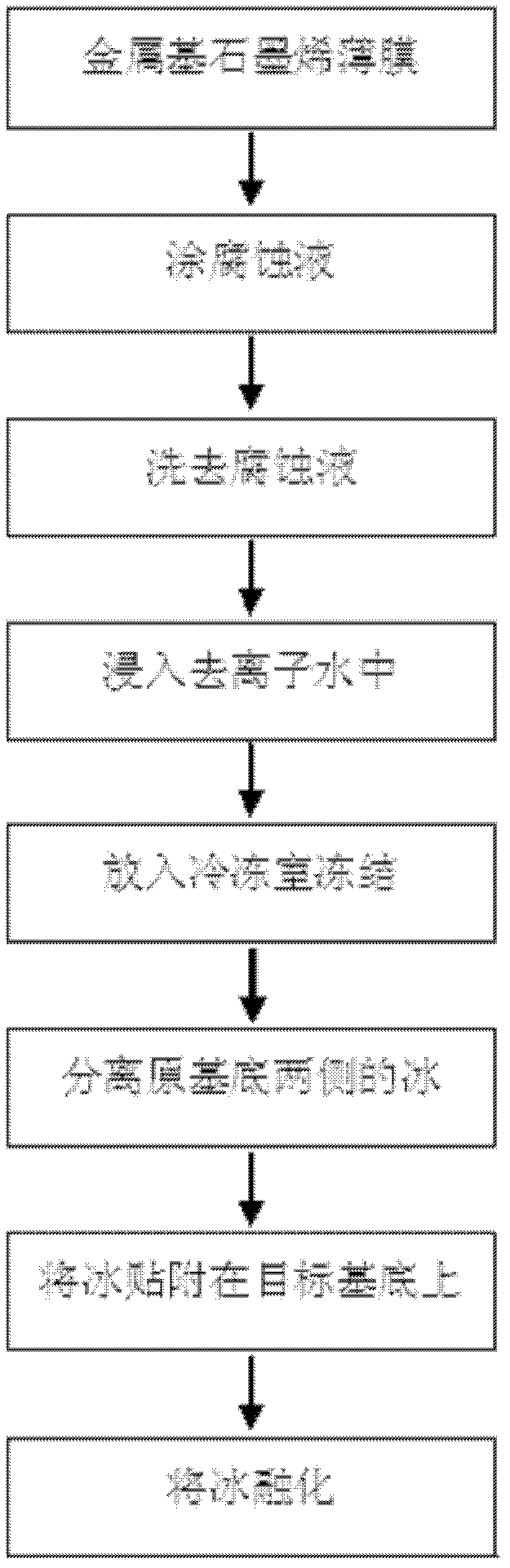

Method used

Image

Examples

Embodiment 1

[0038] The method for transferring the graphene film on the metal copper substrate to the quartz substrate comprises the following steps:

[0039] (1) The spraying concentration of 1mol / L FeCl is sprayed on the graphene film of the Cu substrate by spray gun spraying 3 solution, which weakens the adhesion between the graphene film and the copper substrate;

[0040] (2) putting the copper-based graphene film processed in step (1) into deionized water and soaking at room temperature for 5 minutes, and washing away the residual corrosion solution;

[0041] (3) after step (2) washes off residual corrosion solution, the graphene film of copper base is vertically put into the water tank that fills deionized water, makes the sample both sides all have the water that thickness is 0.5cm; Put the water tank with the sample in the freezer, keep the temperature of the freezer at about -10°C, and make the water with a thickness of 0.5 cm on both sides of the sample condense into ice;

[0...

Embodiment 2

[0046] Transfer of graphene films from copper substrates to SiO 2 / Si substrate,

[0047] The specific steps are similar to Example 1, but the target substrate used is SiO 2 / Si substrate, and repeat steps (1)-(5), the graphene of double-layer quartz substrate can be obtained.

Embodiment 3

[0049] Transfer of graphene films from copper substrates to TiO 2 base,

[0050] The specific steps are similar to Example 1, but the target substrate used is TiO 2 Substrate, and repeat steps (1)-(5) 2 times, can get to the graphene of three layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com