Preparation method of novel magnetic nano biosorption material

A biosorption and magnetic technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of cumbersome methods, time-consuming, difficult separation of chitosan-modified chitosan, etc., to expand the application field and expand the surface area , Increase the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

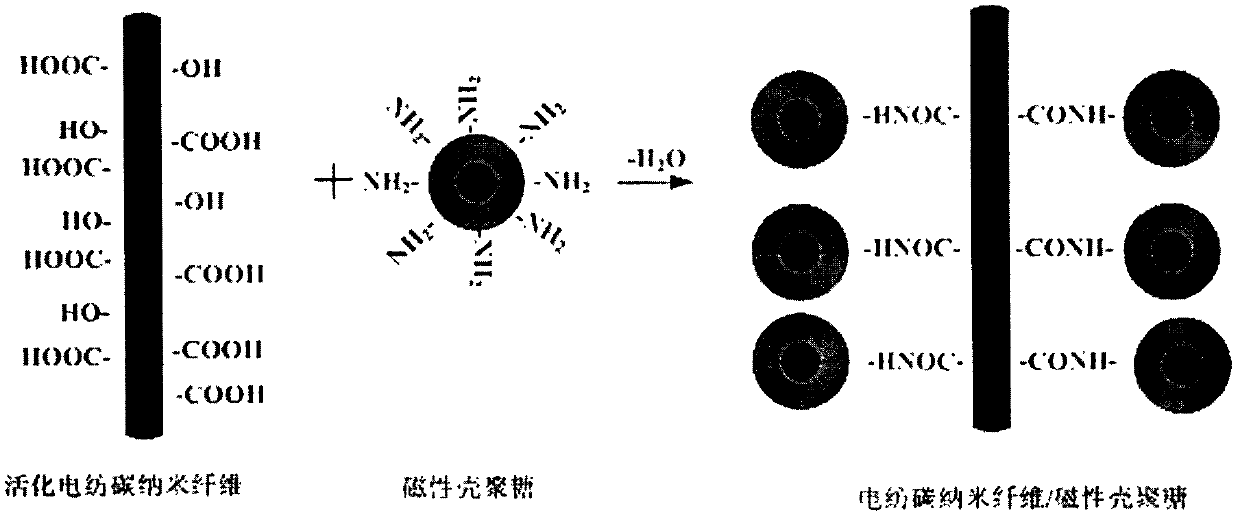

[0018] Example 1: Preparation of carbon nanofiber / magnetic chitosan adsorption material

[0019] A. Preparation of functionalized carbon nanofibers

[0020] Put 0.5g of polyacrylonitrile nanofibers into a tube furnace, raise it from room temperature to 250°C, and then keep it for 2 hours for pre-oxidation treatment; then, under the protection of nitrogen, raise it to 1000°C for high-temperature pyrolysis, and cool naturally to Carbon nanofibers can be obtained at room temperature.

[0021] Add 0.1g of carbon nanofibers to 40mL of mixed acid (1:9 concentrated nitric acid and concentrated sulfuric acid) (in an ice-water bath, add nitric acid first and then sulfuric acid while stirring), heat to reflux in an oil bath at 90°C, and react for 16 hours. Stir for 1 h, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain functionalized carbon nanofibers.

[0022] B. Preparation of Magnetic Chitosan

[0023] Dissolve 0.5g of chitosan in 20mL of 1%...

example 2

[0026] Example 2: Preparation of carbon nanofiber / magnetic chitosan adsorption material

[0027] A. Preparation of functionalized carbon nanofibers

[0028] Put 0.5g of polyacrylonitrile nanofibers into a tube furnace, raise it from room temperature to 300°C, and then keep it for 3 hours for pre-oxidation treatment; then, under the protection of nitrogen, raise it to 1000°C for high-temperature pyrolysis, and cool naturally Unactivated carbon nanofibers can be obtained at room temperature.

[0029] Add 0.1g of carbon nanofibers to 40mL of mixed acid (1:9 concentrated nitric acid and concentrated sulfuric acid) (in an ice-water bath, add nitric acid first and then sulfuric acid while stirring), heat to reflux in an oil bath at 90°C, and react for 18 hours. Stir for 1 h, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain activated carbon nanofibers.

[0030] B. Preparation of Magnetic Chitosan

[0031] Dissolve 0.5g of chitosan in 20mL o...

example 3

[0034] Example 3: Preparation of carbon nanofiber / magnetic chitosan adsorption material

[0035] A. Preparation of functionalized carbon nanofibers

[0036] 0.3g of polyacrylonitrile nanofibers were placed in a tube furnace, raised from room temperature to 280°C, and then kept for 3 hours for pre-oxidation treatment; then under the protection of nitrogen, raised to 1100°C for high-temperature pyrolysis, and naturally cooled to Unactivated carbon nanofibers can be obtained at room temperature.

[0037] Add 0.1g of carbon nanofibers to 40mL of mixed acid (1:5 concentrated nitric acid and concentrated sulfuric acid) (in an ice-water bath, add nitric acid first and then sulfuric acid under stirring), heat to reflux in an oil bath at 90°C, and react for 17 hours. Stir for 1 h, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain activated carbon nanofibers.

[0038] B. Preparation of Magnetic Chitosan

[0039] Dissolve 0.5g of chitosan in 20m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com