Solar selective absorbing coating as well as preparation method and application thereof

An absorption coating, selective technology, applied in the direction of coating, metal material coating process, layered products, etc., can solve the problems of poor thermal stability, low use temperature, etc., to achieve the best thermal stability, cost economy, preparation Simple and clean method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] Preparation method of solar selective absorbing coating

[0069] The preparation method of the solar energy selective absorption coating of the present invention comprises the following steps:

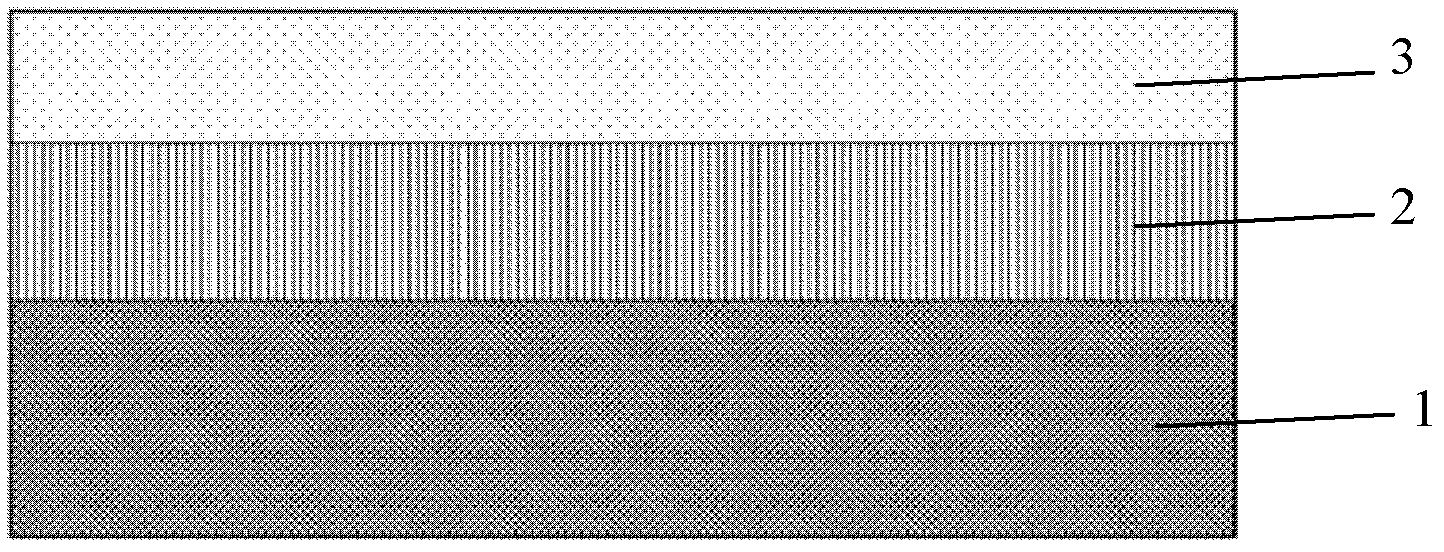

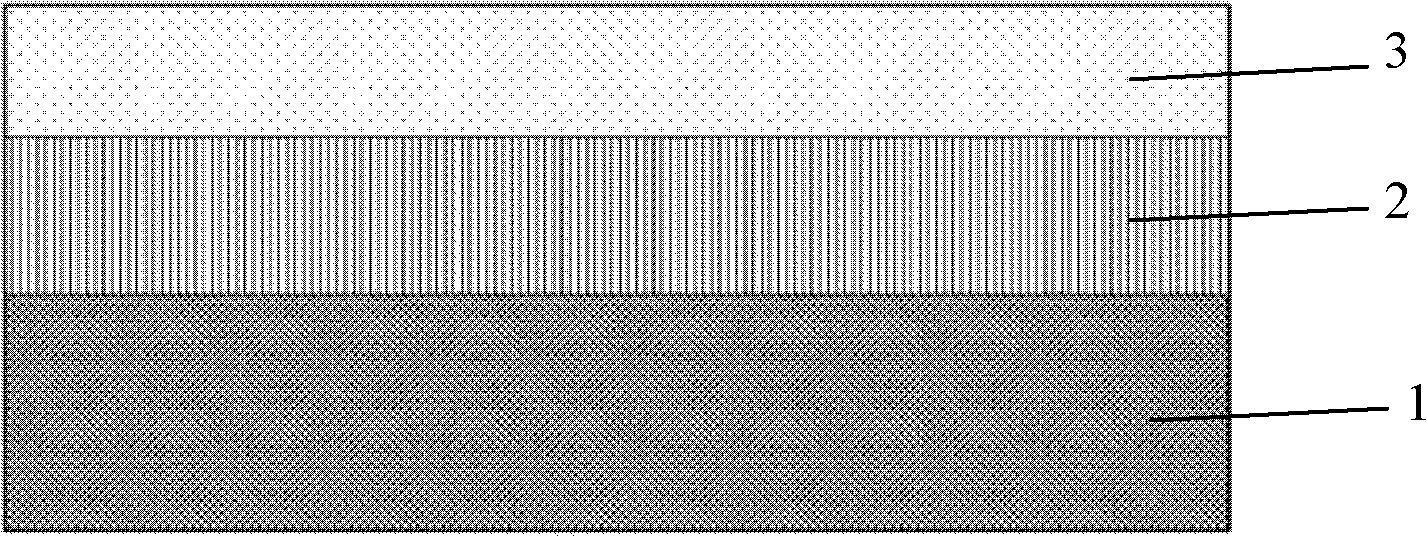

[0070] (a) forming a TiAlN film layer as an absorber layer on a substrate;

[0071] (b) forming SiO on the absorber layer 2 The thin film layer acts as an anti-reflection layer.

[0072] The method for forming the TiAlN thin film layer on the substrate in the step (a) can adopt methods commonly used in the art, such as multi-arc ion plating, evaporation, or DC magnetron sputtering.

[0073] SiO is formed on the absorber layer in the step (b) 2 The method of thin film layer can adopt the method commonly used in this field, such as radio frequency magnetron sputtering method, pulse reaction magnetron sputtering method, chemical vapor deposition method, oxidation method, sol-gel method, or liquid phase deposition method.

[0074] Preferably, the preparation method of the solar ...

Embodiment 1

[0124] Preparation of Solar Selective Absorbing Coatings

[0125] A polished copper sheet was used as the base material, ultrasonically cleaned in acetone for 30 minutes, dried and placed in the sample stage of the chamber of the magnetron sputtering equipment.

[0126] Use mechanical pump and molecular pump to vacuumize the chamber, when the vacuum degree of the chamber reaches 7×10 -4 After Pa, pass high-purity argon gas into the chamber with a flow rate of 20 sccm, adjust the speed of the sample stage when the air pressure in the chamber is 0.1Pa, and turn on the ion source with a voltage of 150V to clean the surface of the substrate material by ion bombardment.

[0127] After cleaning for 20 minutes, high-purity argon and high-purity nitrogen were introduced into the chamber, the flow rate was 30 sccm and 5 sccm, and the sputtering pressure was 0.1 Pa, and the preparation of TiAlN thin film was carried out: using TiAl alloy target material, applied on two The power on the...

Embodiment 2

[0133] Preparation of Solar Selective Absorbing Coatings

[0134] Polished stainless steel was used as the substrate material, ultrasonically cleaned in acetone for 30 minutes, dried and placed in the sample stage of the chamber of the magnetron sputtering equipment.

[0135] Use mechanical pump and molecular pump to vacuumize the chamber, when the vacuum degree of the chamber reaches 7×10 -4 After Pa, pass high-purity argon gas into the chamber with a flow rate of 20 sccm, adjust the speed of the sample stage when the air pressure in the chamber is 0.1 Pa, and turn on the ion source with a voltage of 200V to clean the surface of the substrate material by ion bombardment.

[0136] After cleaning for 20 minutes, high-purity argon and high-purity nitrogen were introduced into the chamber, the flow rate was 30 sccm and 5 sccm, and the sputtering pressure was 0.1 Pa, and the preparation of TiAlN thin film was carried out: using TiAl alloy target material, applied on two The power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com