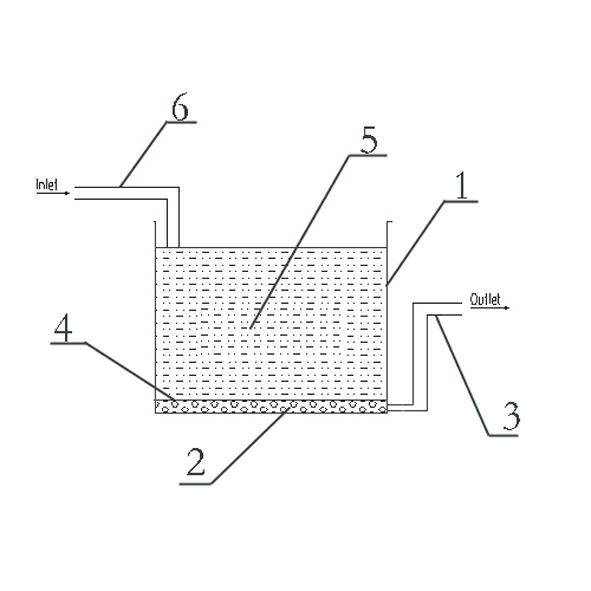

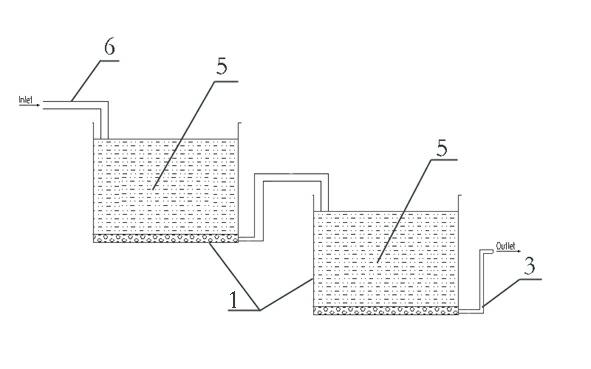

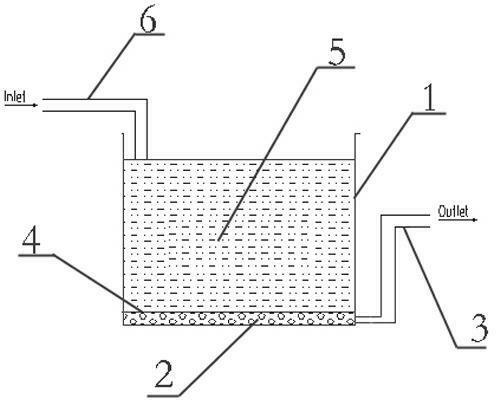

Vertical flow constructed wetland used for treating paint wastewater containing lead and cadmium and preparation method thereof

A paint wastewater and artificial wetland technology, applied in waste paint treatment, sustainable biological treatment, chemical instruments and methods, etc., to achieve the effects of avoiding changes in water load, saving costs, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of vertical flow artificial wetland that is used to process lead, cadmium paint waste water and phosphorous waste water, it is characterized in that comprising the following wetland matrix material by weight ratio:

[0035] Soil, 150 ~ 250 parts by weight;

[0036] Fine sand with a particle size of 0.15-0.25 mm, 200-300 parts by weight;

[0037] Gravel with a particle size of 20-40 mm, 200-350 parts by weight;

[0038] 100-200 parts by weight of fine coal slag with a particle size of 2-10 mm;

[0039] Sludge, 100-150 parts by weight.

[0040] Under the conditions of continuous water inflow concentration of 200~600mg / L and continuous water inflow time of 24 hours, the substrate can remove more than 60% of phosphorus in the water body.

[0041] Under the condition that the influent Pb concentration is 10~160mg / L, the influent Cd concentration is 5~50mg / L, and the continuous water inflow time is 24 hours, the removal rate of heavy metal ions in the ...

Embodiment 2

[0042] Embodiment 2: Same as Embodiment 1, except that: the following wetland matrix material in proportion by weight is also included: fly ash (average particle size: 10-20 μm): 130-180 parts by weight.

[0043] Under the conditions of continuous water inflow concentration of 200~600mg / L and continuous water inflow time of 24 hours, the substrate can remove more than 70% of phosphorus in the water body.

[0044] Under the condition that the influent Pb concentration is 10~160mg / L, the influent Cd concentration is 5~50mg / L, and the continuous water inflow time is 24 hours, the removal rate of heavy metal ions in the water body by the matrix can reach more than 90%.

Embodiment 3~9

[0045] Embodiments 3 to 9: the same as Embodiment 1, the difference is that: the wetland matrix material is composed of the following materials in proportion by weight:

[0046] Table 1 Ratio of wetland matrix materials

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com