Urethane acrylate intermediate of adhesive for bonding touch screen and preparation method thereof

A polyurethane acrylate, touch screen technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of decreased light transmission performance, strong shrinkage stress, poor bonding strength, etc., and achieve shrinkage rate. Low, flexible and weather resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

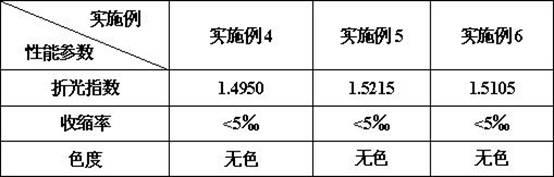

Examples

Embodiment 1

[0027] Embodiment 1, a kind of urethane acrylate intermediate of glue for bonding touch screen, it is made of the raw materials of following weight ratio:

[0028] Polyether polyol 55; Polyol phosphate 1;

[0029] Mercapto polyether polyol 1; Diisocyanate 7;

[0030] Catalyst 0.1; Antioxidant 0.3;

[0031] Thinner 15; Capping agent 1;

[0032] Stabilizer 0.1;

[0033] The polyether polyol is selected from polypropylene glycol with a molecular weight of 2000 to 3000, polyoxypropylene glycol, polytetrahydrofuran diol, and one or any mixture of grafted polyether polyols;

[0034] The polyol phosphate is selected from one of monobasic polyoxyethylene ether phosphates, dibasic polyoxyethylene ether phosphates, phosphonate mixed esters of monobasic polyhydroxy compounds, phosphonate mixed esters of dibasic polyhydroxy compounds or any mixture of

[0035] Described mercapto polyether polyol is mercapto polyether polyol;

[0036] The diisocyanate is selected from one or any mixt...

Embodiment 2

[0042] Embodiment 2, a kind of urethane acrylate intermediate of glue for bonding touch screen, it is made of the raw materials of following weight ratio:

[0043] Polyether polyol 75; 3;

[0044] Mercapto polyether polyol 3; Diisocyanate 15;

[0045]Catalyst 0.5; Antioxidant 0.6;

[0046] Diluent 40; Capping agent 5;

[0047] Stabilizer 0.3;

[0048] The selection of each raw material is the same as in Example 1.

[0049] The steps of the preparation method of the urethane acrylate intermediate of the touch screen bonding glue in this embodiment are as follows: vacuumize and dehydrate polyether polyol, polyol phosphate, and mercapto polyether polyol at a temperature of 80°C according to the weight ratio 1 hour; then, add catalyst, diisocyanate and stir fully at 85°C, react for 3 hours, until the content of isocyanate is less than 2%, add antioxidant, stabilizer, diluent and blocking agent, react for 2 hours; Finally, the temperature was lowered to 70° C., and the materia...

Embodiment 3

[0050] Embodiment 3, a kind of urethane acrylate intermediate of glue for bonding touch screen, it is made of the raw materials of following weight ratio:

[0051] Polyether polyol 65; Polyol phosphate 2;

[0052] Mercapto polyether polyol 2; Diisocyanate 12;

[0053] Catalyst 0.3; Antioxidant 0.4;

[0054] Thinner 30; Capping agent 2;

[0055] Stabilizer 0.2;

[0056] The selection of each raw material is the same as in Example 1.

[0057] The steps of the preparation method of the urethane acrylate intermediate of the adhesive for touch screen bonding in this embodiment are as follows: vacuumize the polyether polyol, polyol phosphate, and mercapto polyether polyol at a temperature of 80°C according to the weight ratio Dehydration for 2 hours; then, add catalyst, diisocyanate and stir well at 90°C, react for 4 hours, until the content of isocyanate is less than 2%, add antioxidant, stabilizer, diluent and blocking agent, react for 4 hours ; Finally, the temperature was l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com