Method for preparing lignosulfonate from papermaking pulping red liquor

A technology for lignosulfonate and pulping, which is applied in the preparation of sugar derivatives, chemical instruments and methods, monosaccharides, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

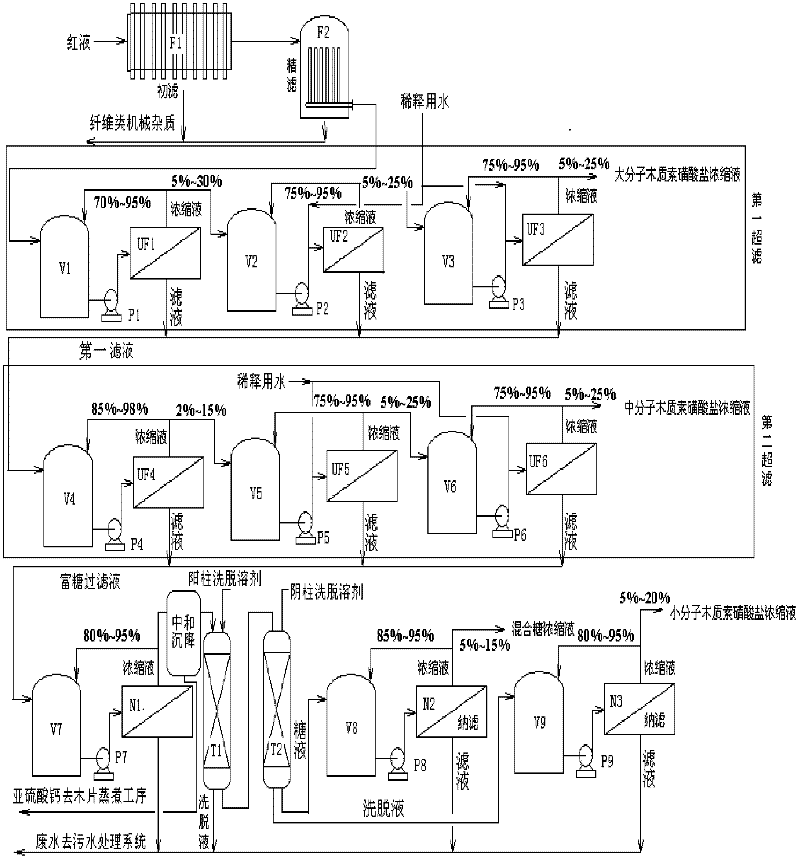

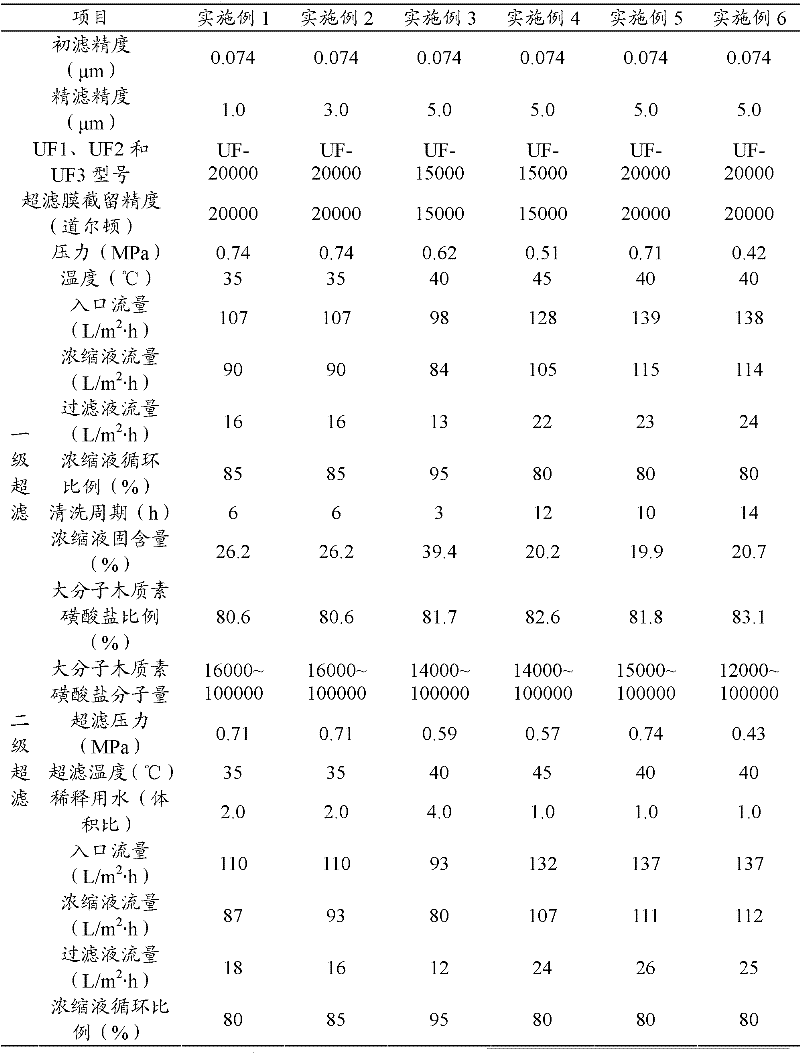

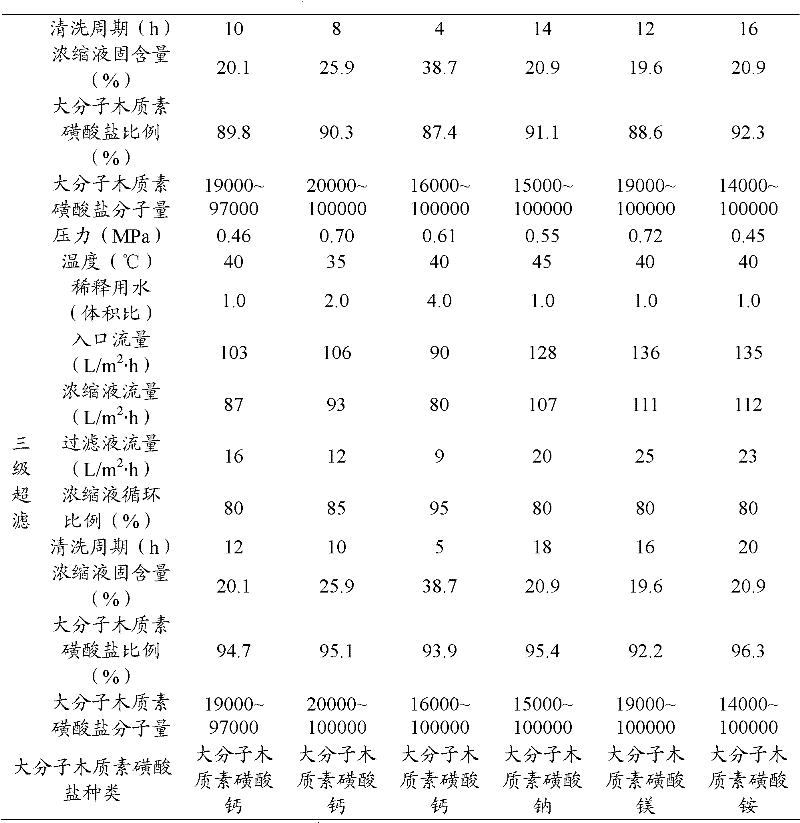

[0088] Using 2634.8L, pH value of 1.85 acidic sulfite cooking red liquor of coniferous wood as raw material, according to figure 1 The process flow shown prepares calcium lignosulfonate and monosaccharide, see Table 1, Table 2 and Table 3 for relevant parameters of the preparation process, and Table 1 is the experimental conditions and results for the preparation of macromolecular lignosulfonate in the embodiment of the present invention; Table 2 shows the experimental conditions and results for the preparation of middle-molecular lignosulfonate in the examples of the present invention; Table 3 shows the experimental conditions and results for the preparation of monosaccharide and small-molecular lignosulfonates in the examples of the present invention.

[0089] Based on the total amount of lignosulfonate in the red liquid stock solution, the yield of macromolecular calcium lignosulfonate was calculated to be 19.86%, the yield of medium molecular calcium lignosulfonate was 37.2...

Embodiment 2

[0091] Add milk of lime to 2260L, pH value of 2.01 acid sulphite cooking red liquor of coniferous wood, adjust its pH value to 4.86, according to figure 1 The process flow shown prepares calcium lignosulfonate and monosaccharide, see Table 1, Table 2 and Table 3 for relevant parameters of the preparation process, and Table 1 is the experimental conditions and results for the preparation of macromolecular lignosulfonate in the embodiment of the present invention; Table 2 shows the experimental conditions and results for the preparation of middle-molecular lignosulfonate in the examples of the present invention; Table 3 shows the experimental conditions and results for the preparation of monosaccharide and small-molecular lignosulfonates in the examples of the present invention.

[0092] Taking the total amount of lignosulfonate in the red liquid stock solution as a benchmark, the yield of macromolecular calcium lignosulfonate was calculated to be 22.1%, the yield of medium molec...

Embodiment 3

[0094] Add milk of lime to 2400L, pH value of 1.93 acid sulfite cooking red liquor of coniferous wood, adjust its pH value to 5.01, according to figure 1 The process flow shown prepares calcium lignosulfonate and monosaccharide, see Table 1, Table 2 and Table 3 for relevant parameters of the preparation process, and Table 1 is the experimental conditions and results for the preparation of macromolecular lignosulfonate in the embodiment of the present invention; Table 2 shows the experimental conditions and results for the preparation of middle-molecular lignosulfonate in the examples of the present invention; Table 3 shows the experimental conditions and results for the preparation of monosaccharide and small-molecular lignosulfonates in the examples of the present invention.

[0095] Based on the total amount of lignosulfonate in the red liquid stock solution, the calculated yield of macromolecular sodium lignosulfonate is 9.47%, the yield of medium molecular sodium lignosulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com