Casting polyurethane/diatomite composite material and preparation method thereof

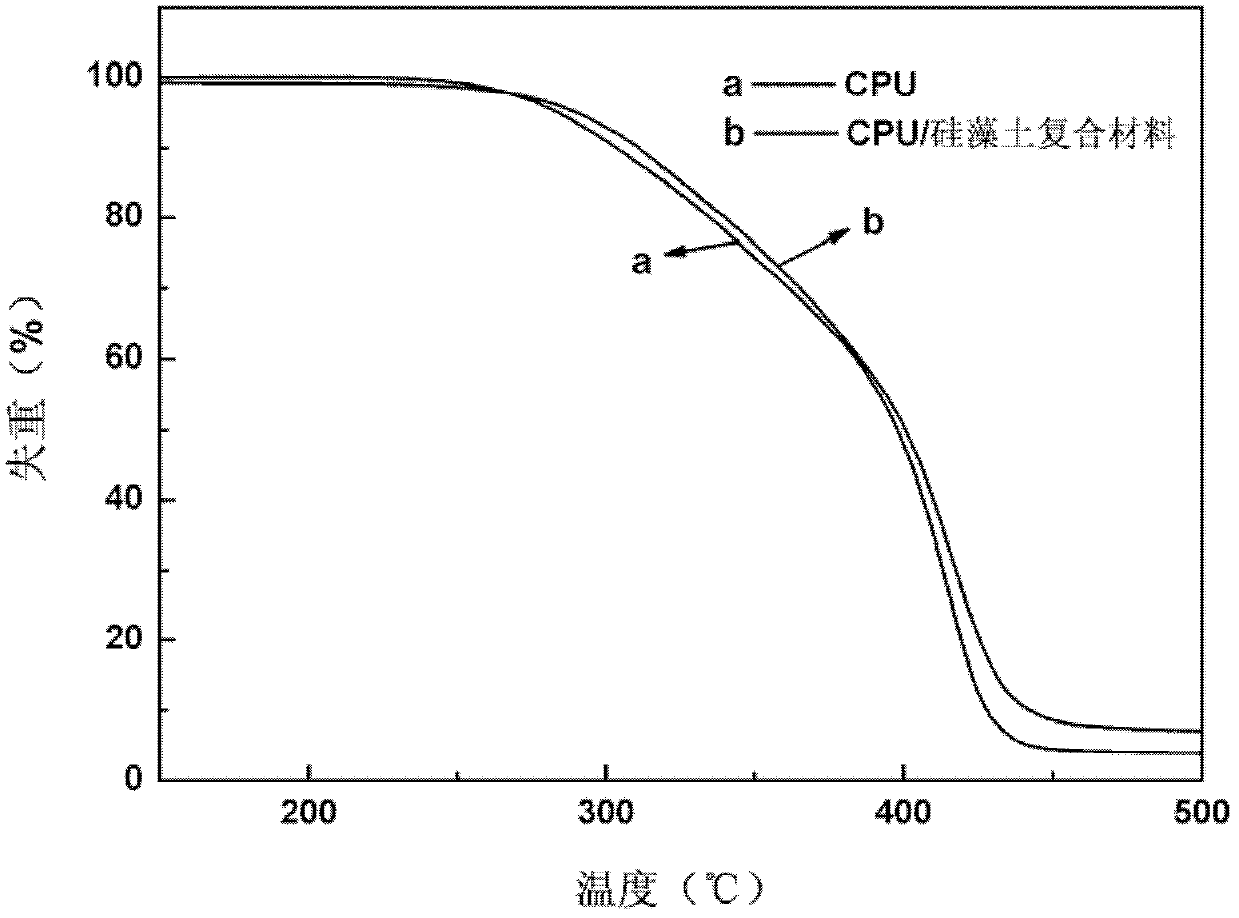

A composite material and diatomite technology, which is applied in the field of casting polyurethane/diatomite composite material and its preparation, can solve the problems such as the diatomite modified CPU composite material which has not been seen, and achieve the improvement of mechanical properties and heat resistance, The effect of low energy consumption and convenient processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

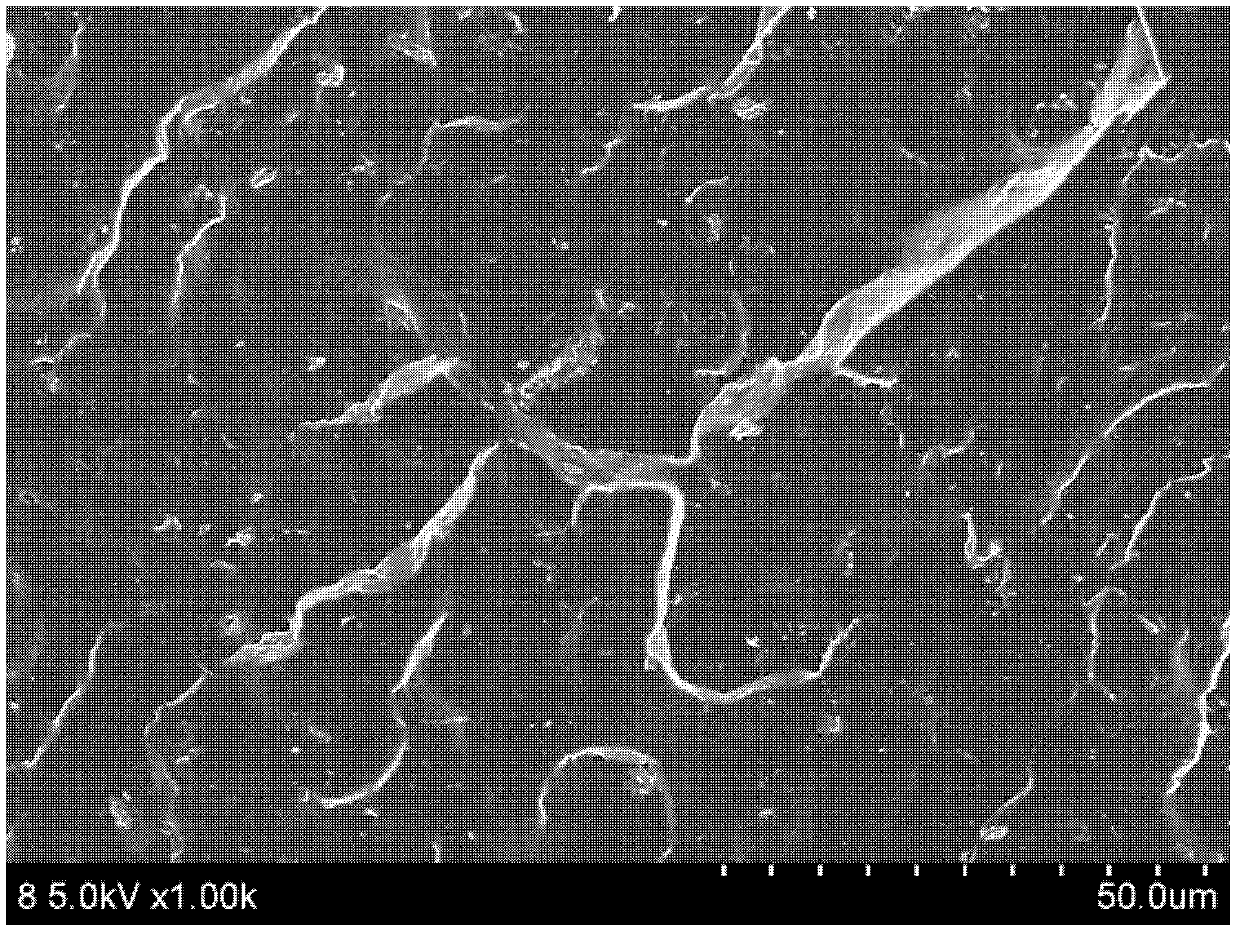

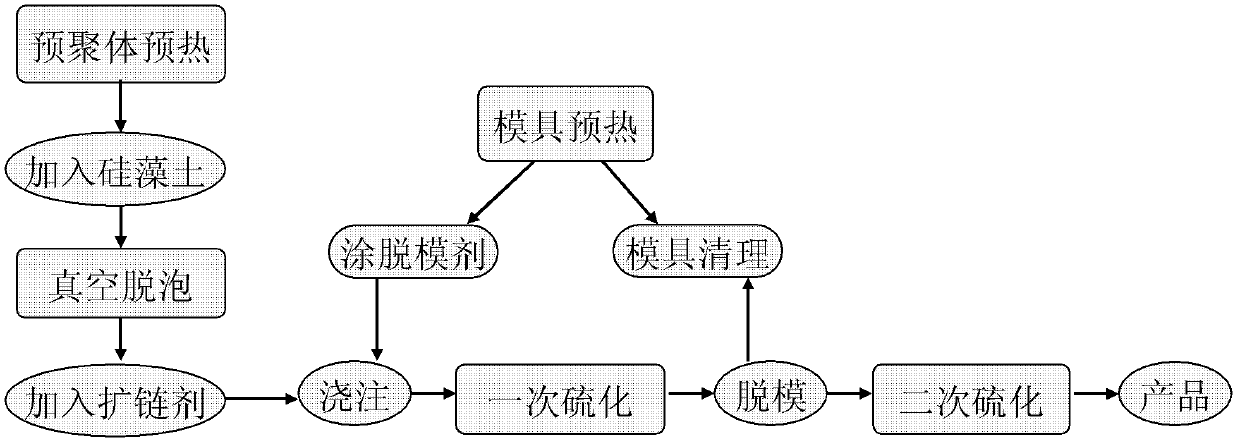

[0030] (1) Weigh 20g diatomaceous earth with a particle size of 2000 mesh and add it to a three-necked flask, then add 400mL cyclohexane, 0.4g n-propylamine and 2g silane coupling agent KH-560, and stir at room temperature for 30min at a stirring speed of 500r / min , And then stirred at 50°C for 30 min. Rotary evaporate the reacted solution at 60°C for 1 hour, then vacuum dry at 60°C for 30 hours, and collect diatomaceous earth;

[0031] (2) Weigh 100g of prepolymer (NCO-based mass content is 5.0±0.2%) and preheat it at 80℃ for 1h, then weigh 0.5g of modified diatomaceous earth and add it to the above prepolymer. Mix and stir for 10min at 500r / min. The resulting mixture was then placed in a vacuum drying oven at 80°C for vacuum degassing for 10 minutes. Weigh 21.4g of M-CDEA chain extender, heat and melt at 110°C, add it to the above mixture, and mix and stir for 40s at a stirring speed of 500r / min. Then the obtained mixture was poured into a mold and placed on a plate vulcaniz...

Embodiment 2

[0033] (1) Weigh 25g of diatomaceous earth with a particle size of 2000 mesh and add it to a three-necked flask, then add 550mL of cyclohexane, 0.4g of n-propylamine and 3g of silane coupling agent KH-550, and stir at room temperature for 40min at a stirring speed of 600r / min , And then stirred at 60°C for 40 min. Rotary evaporate the reacted solution at 70°C for 1 hour, then vacuum dry at 65°C for 28 hours, and collect diatomaceous earth;

[0034] (2) Weigh 100g of prepolymer (NCO content is 5.0±0.2%) and preheat it at 85℃ for 1.5h, then weigh 1g of modified diatomaceous earth and add it to the above prepolymer at a stirring speed of Mix and stir for 20 minutes at 600r / min. Subsequently, the resulting mixture was placed in a vacuum drying oven at 85°C for vacuum degassing for 20 minutes. Weigh 21.4g of M-CDEA chain extender, heat and melt at 115°C, add to the above mixture, mix and stir for 45s at a stirring speed of 600r / min. Then the obtained mixture was poured into a mold ...

Embodiment 3

[0036] (1) Weigh 30g of diatomaceous earth with a particle size of 2000 mesh and add it to a three-necked flask, then add 700mL of cyclohexane, 0.5g of n-propylamine and 4g of silane coupling agent KH-570, and stir for 50min at room temperature at a stirring speed of 650r / min , And then stirred at 60°C for 50 min. Rotary evaporate the reacted solution at 80°C for 50 minutes, then vacuum dry at 70°C for 24 hours, and collect diatomaceous earth;

[0037] (2) Weigh 100g of prepolymer (NCO content is 5.0±0.2%) and preheat at 88℃ for 2h, then weigh 3g of modified diatomaceous earth and add it to the above prepolymer at a stirring speed of 650r Mix and stir for 25 min at / min. The resulting mixture was then placed in a vacuum drying oven at 88°C for vacuum degassing for 25 minutes. Weigh 21.4g of M-CDEA chain extender, heat and melt at 120°C, add to the above mixture, and mix and stir for 50s at a stirring speed of 650r / min. Then the obtained mixture was poured into a mold, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com