Aqueous adhesive and preparation method thereof

A technology of water-based adhesives and additives, applied in the direction of adhesives, adhesive additives, monocarboxylic acid ester copolymer adhesives, etc., can solve the problems of insufficient adhesion, poor water resistance, singleness, etc., and achieve moderate cost and water resistance Good performance, the effect of expanding production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A water-based adhesive, with ethylene-vinyl acetate copolymer emulsion and polyurethane emulsion as main raw materials, and its components are by weight:

[0027] 20 parts of ethylene-vinyl acetate copolymer emulsion, 20 parts of polyurethane emulsion, 25 parts of polyvinyl alcohol solution, CaCO 334 parts, 0.3 parts of defoamer, 0.3 parts of bactericide, 0.4 parts of surfactant.

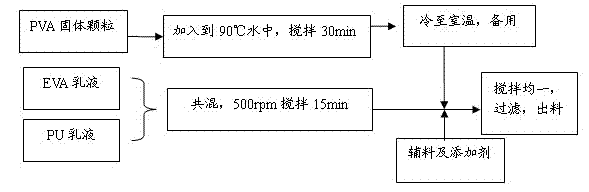

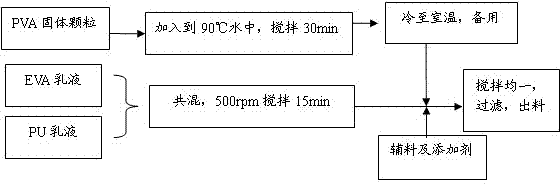

[0028] The method for preparing described water-based adhesive, concrete steps are as follows:

[0029] (1) Add polyvinyl alcohol solid powder into hot water at 90°C, stir for 30 minutes to dissolve it, and obtain a polyvinyl alcohol solution with a mass fraction of 25%, let it stand still, and cool it down to room temperature for later use;

[0030] (2) Add ethylene-vinyl acetate copolymer emulsion and polyurethane emulsion in proportion to the flask, stir at 500rpm for 15min, and add triethanolamine to adjust the pH of the system to 6-7;

[0031] (3) Add polyvinyl alcohol solution with a ...

Embodiment 2

[0033] A water-based adhesive, with ethylene-vinyl acetate copolymer emulsion and polyurethane emulsion as main raw materials, and its components are by weight:

[0034] 25 parts of ethylene-vinyl acetate copolymer emulsion, 23.5 parts of polyurethane emulsion, 30 parts of polyvinyl alcohol solution, CaCO 3 20 parts, 0.45 parts of defoamer, 0.45 part of bactericide, 0.6 part of surfactant.

[0035] The method for preparing described water-based adhesive, concrete steps are as follows:

[0036] (1) Add polyvinyl alcohol solid powder into hot water at 90°C, stir for 30 minutes to dissolve it, and obtain a polyvinyl alcohol solution with a mass fraction of 25%, let it stand still, and cool it down to room temperature for later use;

[0037] (2) Add ethylene-vinyl acetate copolymer emulsion and polyurethane emulsion in proportion to the flask, stir at 500rpm for 15min, and add triethanolamine to adjust the pH of the system to 6-7;

[0038] (3) Add polyvinyl alcohol solution with...

Embodiment 3

[0040] A water-based adhesive, with ethylene-vinyl acetate copolymer emulsion and polyurethane emulsion as main raw materials, and its components are by weight:

[0041] 22 parts of ethylene-vinyl acetate copolymer emulsion, 25 parts of polyurethane emulsion, 27 parts of polyvinyl alcohol solution, CaCO 3 25.65 parts, 0.105 parts of defoamer, 0.105 parts of bactericide, and 0.14 parts of surfactant.

[0042] The method for preparing described water-based adhesive, concrete steps are as follows:

[0043] (1) Add polyvinyl alcohol solid powder into hot water at 90°C, stir for 30 minutes to dissolve it, and obtain a polyvinyl alcohol solution with a mass fraction of 25%, let it stand still, and cool it down to room temperature for later use;

[0044] (2) Add ethylene-vinyl acetate copolymer emulsion and polyurethane emulsion in proportion to the flask, stir at 500rpm for 15min, and add triethanolamine to adjust the pH of the system to 6-7;

[0045] (3) Add polyvinyl alcohol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com