Technique for producing alpha-linoleic acid, silkworm pupa protein and silkworm pupa peptides with silkworm pupas

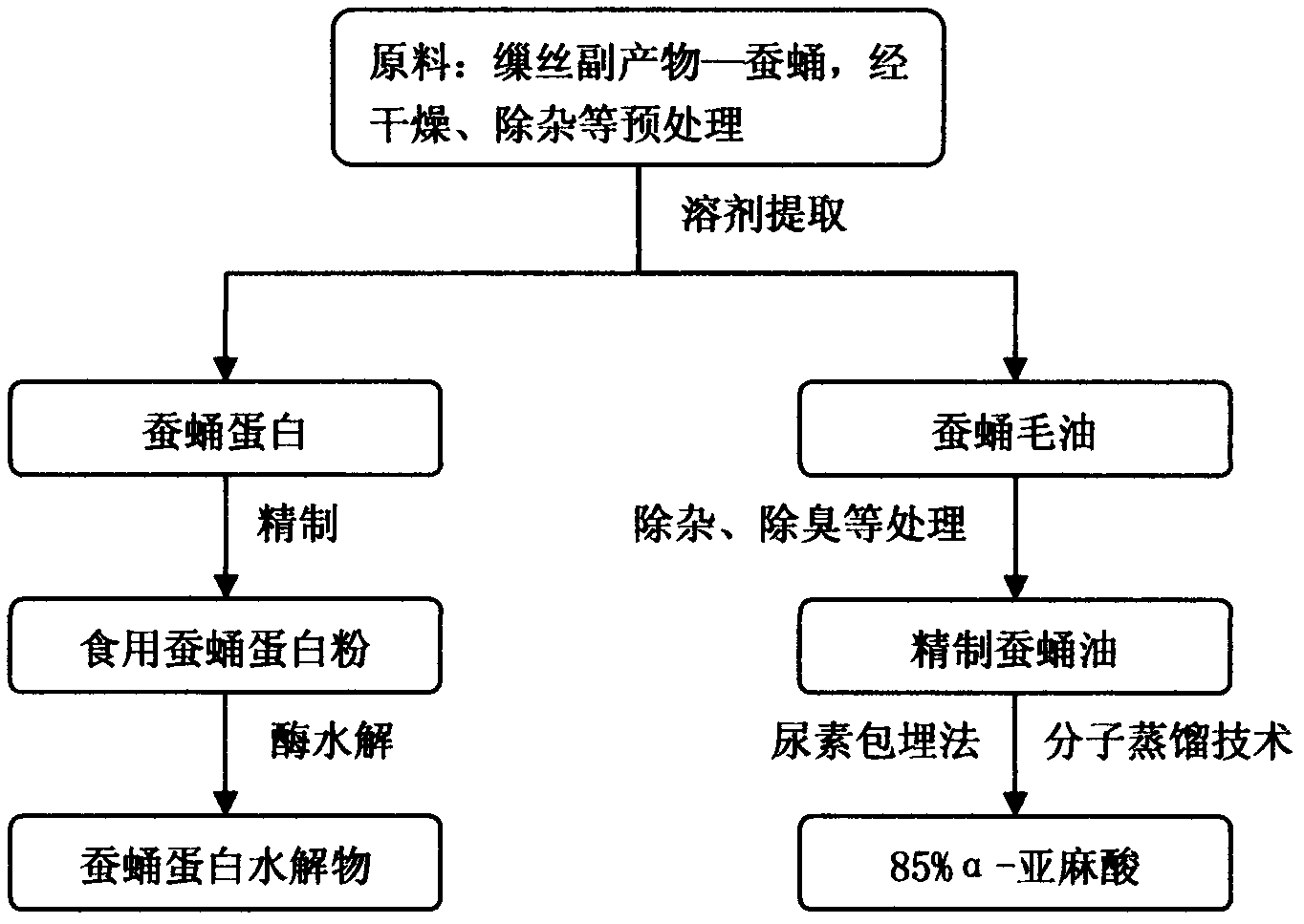

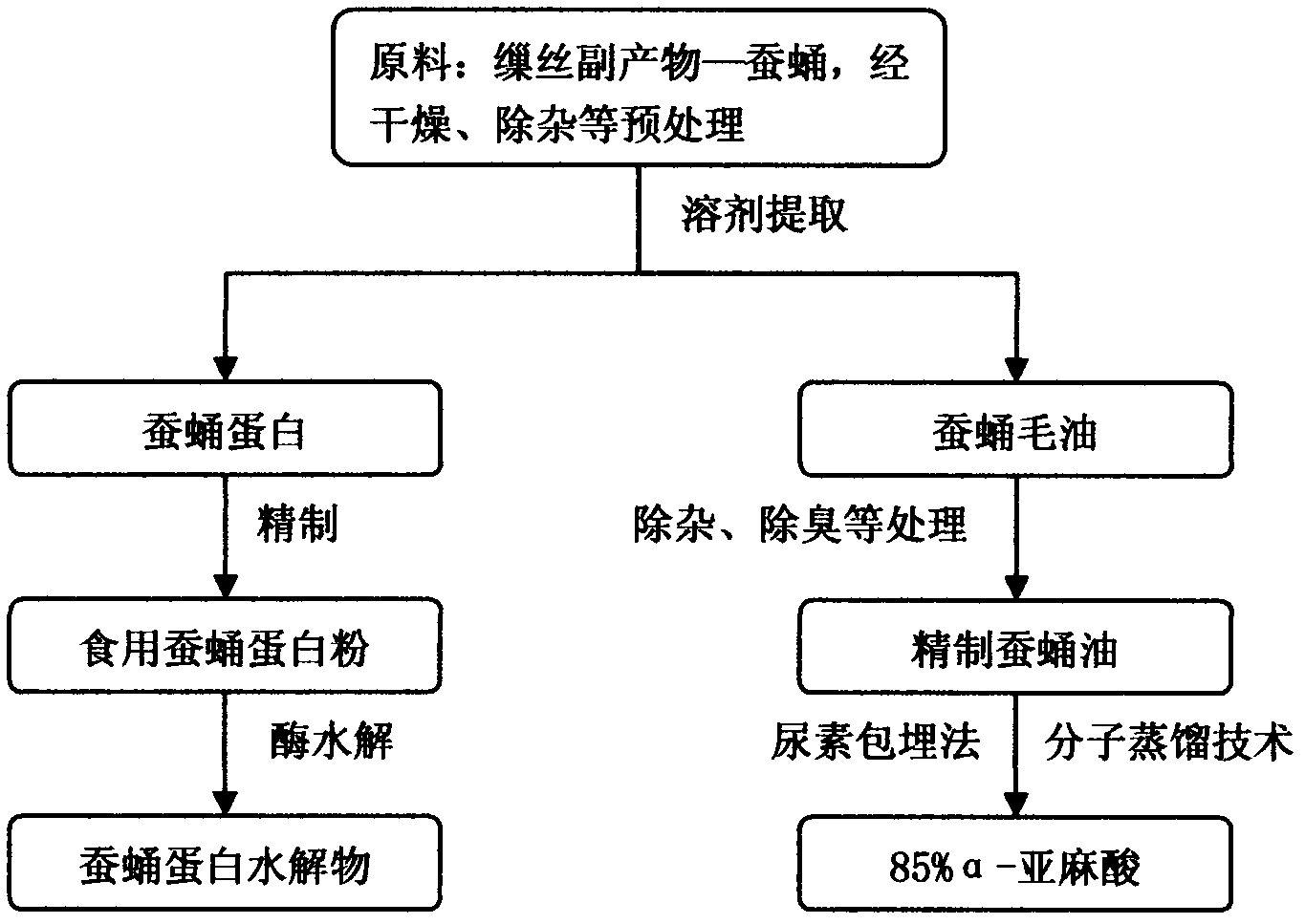

A technology of silkworm chrysalis protein and linolenic acid, which is applied to the extraction of silkworm chrysalis α-linolenic acid and silkworm chrysalis protein, and the preparation of silkworm chrysalis protein hydrolyzate, which can solve the problems affecting the efficacy and low content of α-linolenic acid, and achieve the process of easy mastering , High extraction rate, light color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

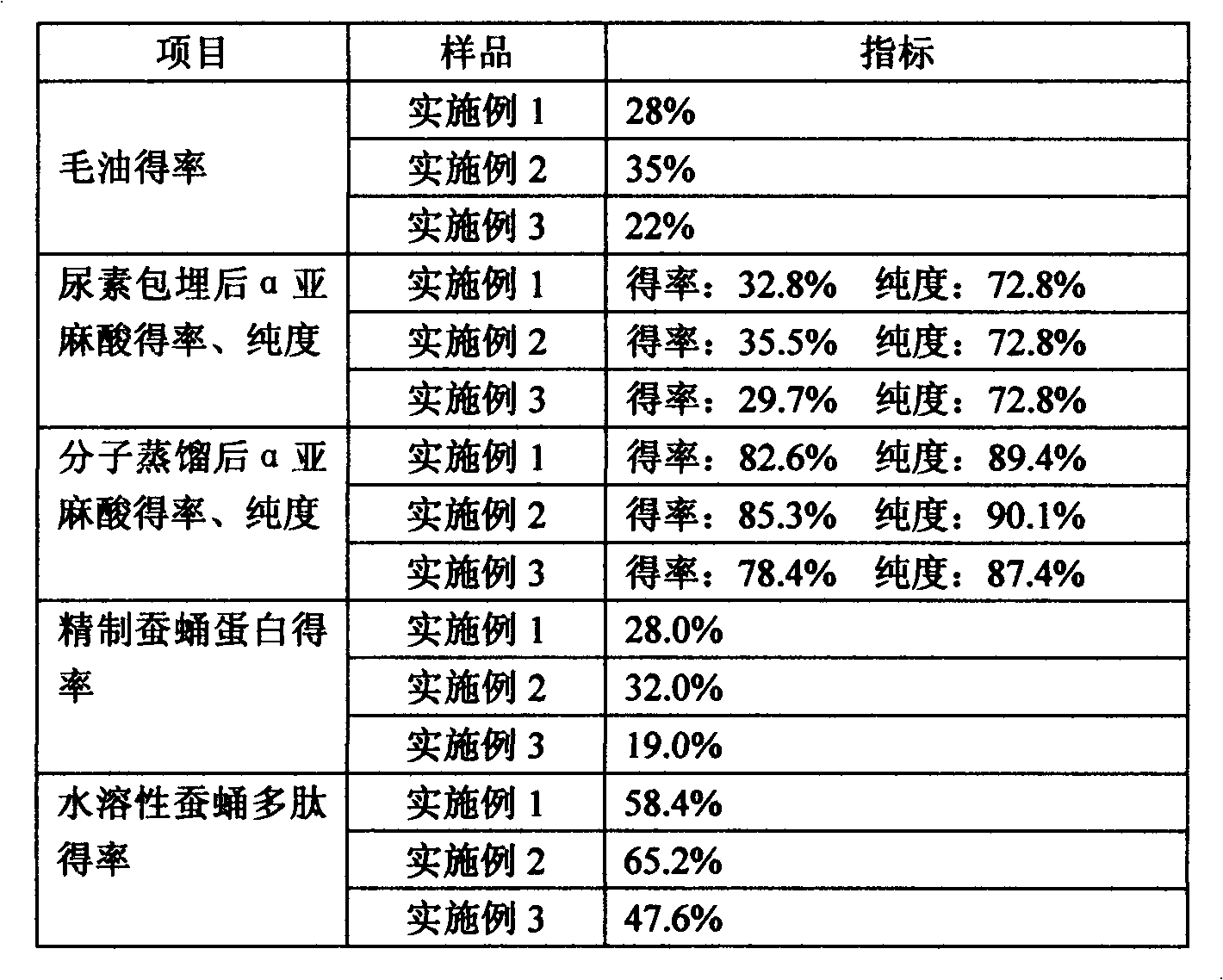

Embodiment 1

[0031] Get the dried silkworm chrysalis, remove visible sundries therein, pulverize with a pulverizer, and pass through a 40-mesh sieve. Take 10 parts by weight of silkworm chrysalis powder in a stainless steel extraction tank, add 60 parts by weight of petroleum ether, heat up rapidly, control the temperature at 65-70° C., and stir for 2 hours. After the extraction was completed, the filtrate was obtained by filtration, the extraction step was repeated once, and the filtrates were combined twice. The solvent of the filtrate was recovered in a solvent recovery device to obtain silkworm chrysalis crude oil; the filter residue was dried in an oven at 50°C for later use. Put the silkworm chrysalis crude oil into the separation tank, add 2 times the amount of 0.1mol / L sodium hydroxide solution, stir at room temperature for 2 hours, let stand until the oil and water are separated, and release the dilute alkali solution from the bottom of the separation tank to obtain refined silkwo...

Embodiment 2

[0038] Take fresh silkworm chrysalis, dry them in an oven at 80°C, remove visible debris, crush them with a pulverizer, and pass through a 40-mesh sieve. Get 10 parts by weight of silkworm chrysalis powder in a stainless steel extraction tank, add 60 parts by weight of an extraction solvent (petroleum ether: acetone=1:1), heat up rapidly, control the temperature at 65-70°C, and stir for 2 hours. After the extraction was completed, the filtrate was obtained by filtration, the extraction step was repeated once, and the filtrates were combined twice. The solvent of the filtrate was recovered in a solvent recovery device to obtain silkworm chrysalis crude oil; the filter residue was dried in an oven at 50°C for later use. Put the silkworm chrysalis crude oil into the separation tank, add 2 times the amount of 0.1mol / L sodium carbonate solution, stir at room temperature for 2 hours, let stand until the oil and water are separated, and release the dilute alkali solution from the bot...

Embodiment 3

[0045] Take the silkworm chrysalis after reeling, dry them in an oven at 80°C, remove visible debris, crush them with a pulverizer, and pass through a 40-mesh sieve. Take 10 parts by weight of silkworm chrysalis powder in a stainless steel extraction tank, add 60 parts by weight of an extraction solvent (acetone:ethanol=1:1), heat up rapidly, control the temperature at 65-70° C., and stir for 2 hours. After the extraction was completed, the filtrate was obtained by filtration, the extraction step was repeated once, and the filtrates were combined twice. The solvent of the filtrate was recovered in a solvent recovery device to obtain silkworm chrysalis crude oil; the filter residue was dried in an oven at 50°C for later use. Put the silkworm chrysalis crude oil into the separation tank, add 2 times the amount of 0.1mol / L sodium carbonate-sodium hydroxide solution, stir at room temperature for 2 hours, let it stand until the oil and water are separated, and release the dilute al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com