Method for detecting biochemical oxygen demand

A technology of biochemical oxygen demand and detection method, applied in the field of biochemical oxygen demand detection, can solve the problems of high price, secondary pollution of the environment, unsuitable for online monitoring, etc., to achieve easier removal, high biodegradation rate, and self-realization repaired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

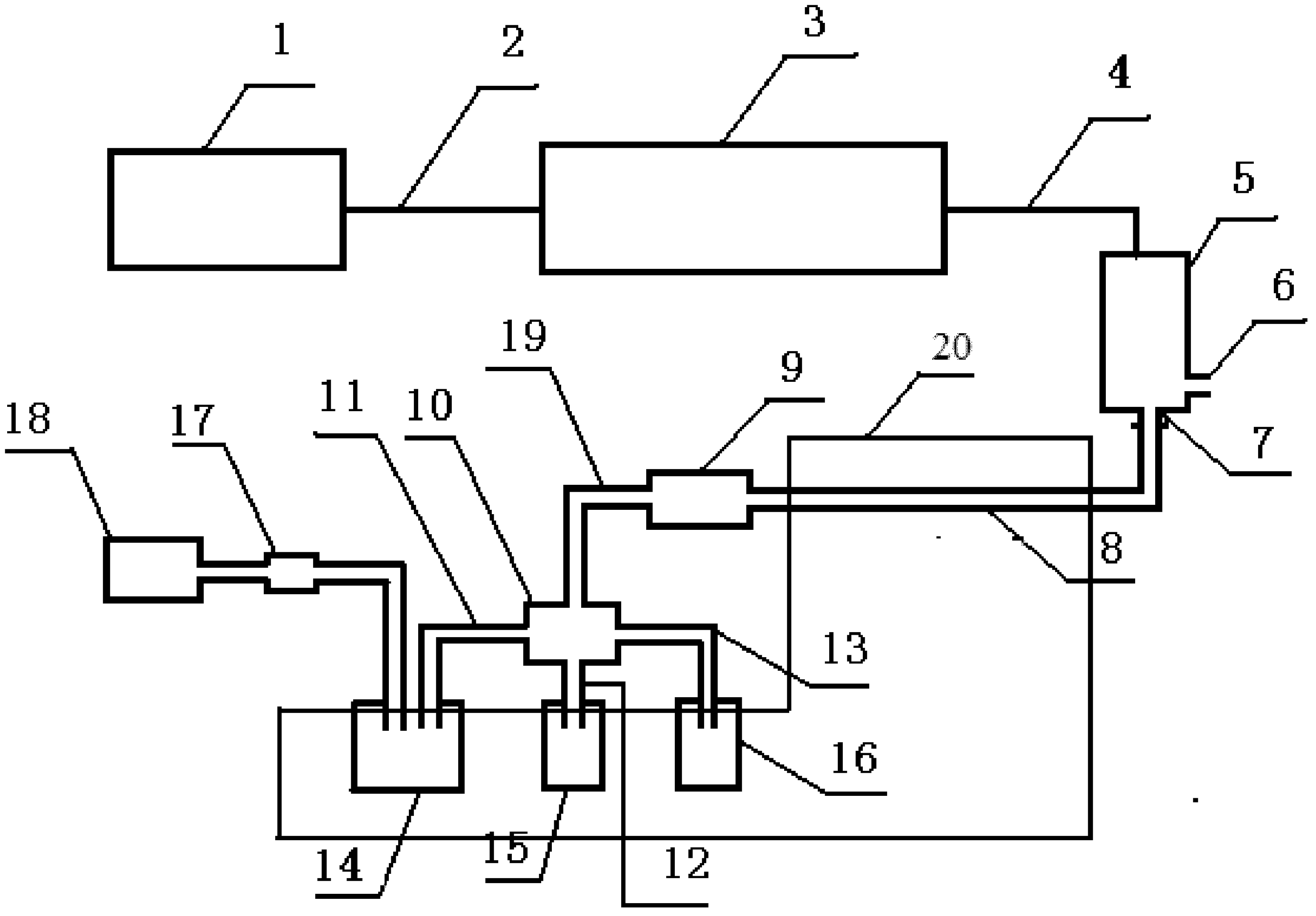

[0115] according to figure 1 Schematic diagram of the preparation of the microbial membrane reactor is shown. One end of the microbial membrane reactor 8 is connected to the oxygen electrode 5, and the oxygen electrode 5 is connected to the electrochemical workstation 3 whose model is CHI832b. The electrochemical workstation 3 monitors the current change of the oxygen electrode 5 and displays it by the computer 1.

[0116] Turn on the constant temperature water bath 20 and adjust the temperature to 30°C. Inject 300 mL of activated sludge water sample from water source 18 into actual water sample container 14 through sample pump 17, and carry out air saturation to the activated sludge water sample at a rate of 3.0 L / min. A glass reactor 8 with a length of 105.0 cm and an inner diameter of 2.0 mm is placed in a constant temperature water bath, and the water sample of the activated sludge passes through the first sampling pipe 11, the solenoid valve 10 and the sampling pipe at a...

Embodiment 2

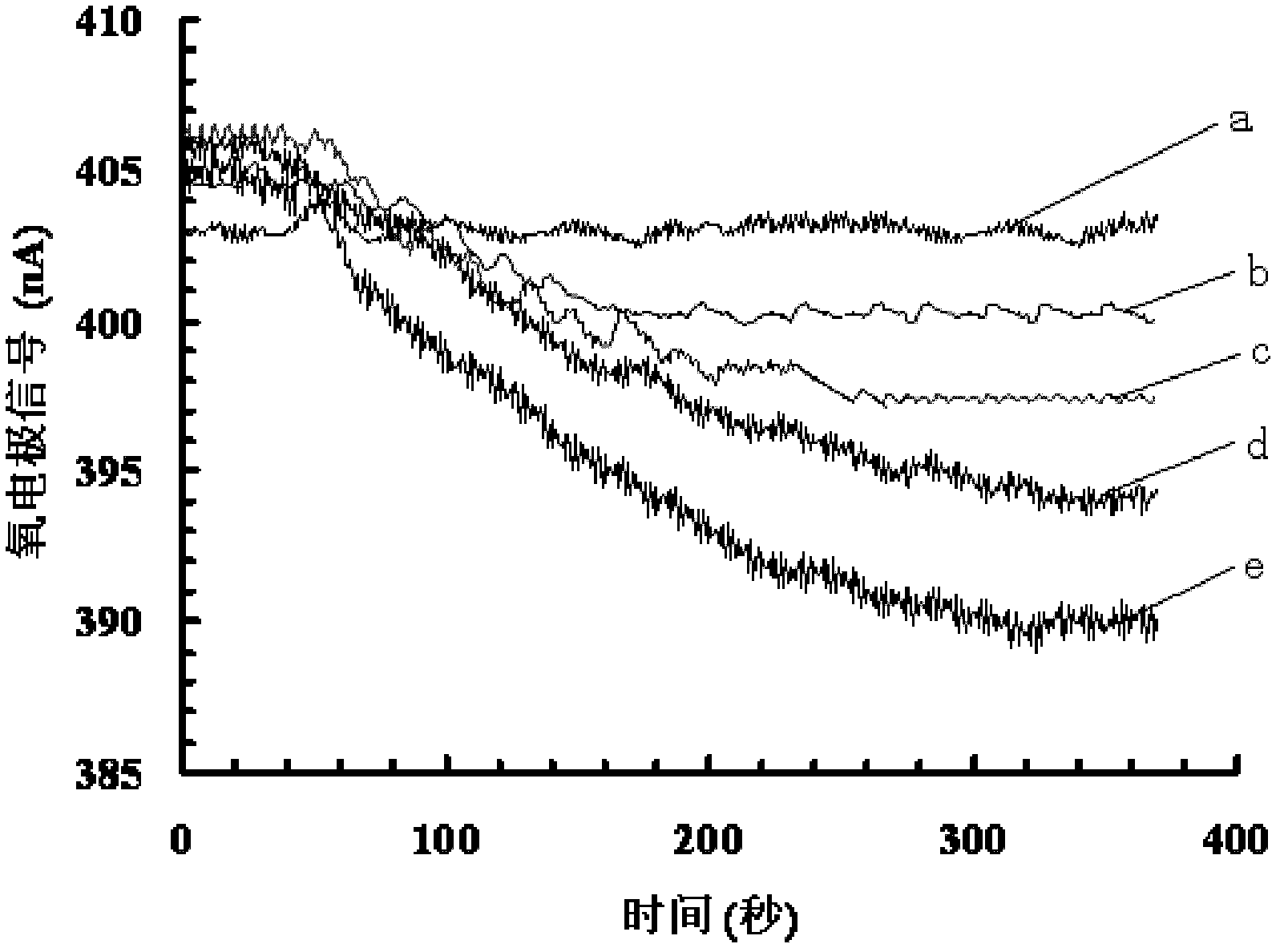

[0118] Turn on the constant temperature water bath 20 and adjust the temperature to 30°C. 300 mL of tap water was poured into the tap water container 15, and it was air-saturated at a rate of 3.0 L / min. Under the control of the peristaltic pump 9, the air-saturated tap water passes through the second sampling pipe 12, the solenoid valve 10, and the sampling pipe 19 at a rate of 1.0 mL / min, reaches the microbial film reactor, and flows through the microbial film After the reactor reaches the surface of the oxygen electrode 5 . The electrochemical workstation 3 monitors the change of the oxygen electrode current, and when the oxygen electrode current is stable, the recorded dissolved oxygen reduction current is 539nA. .

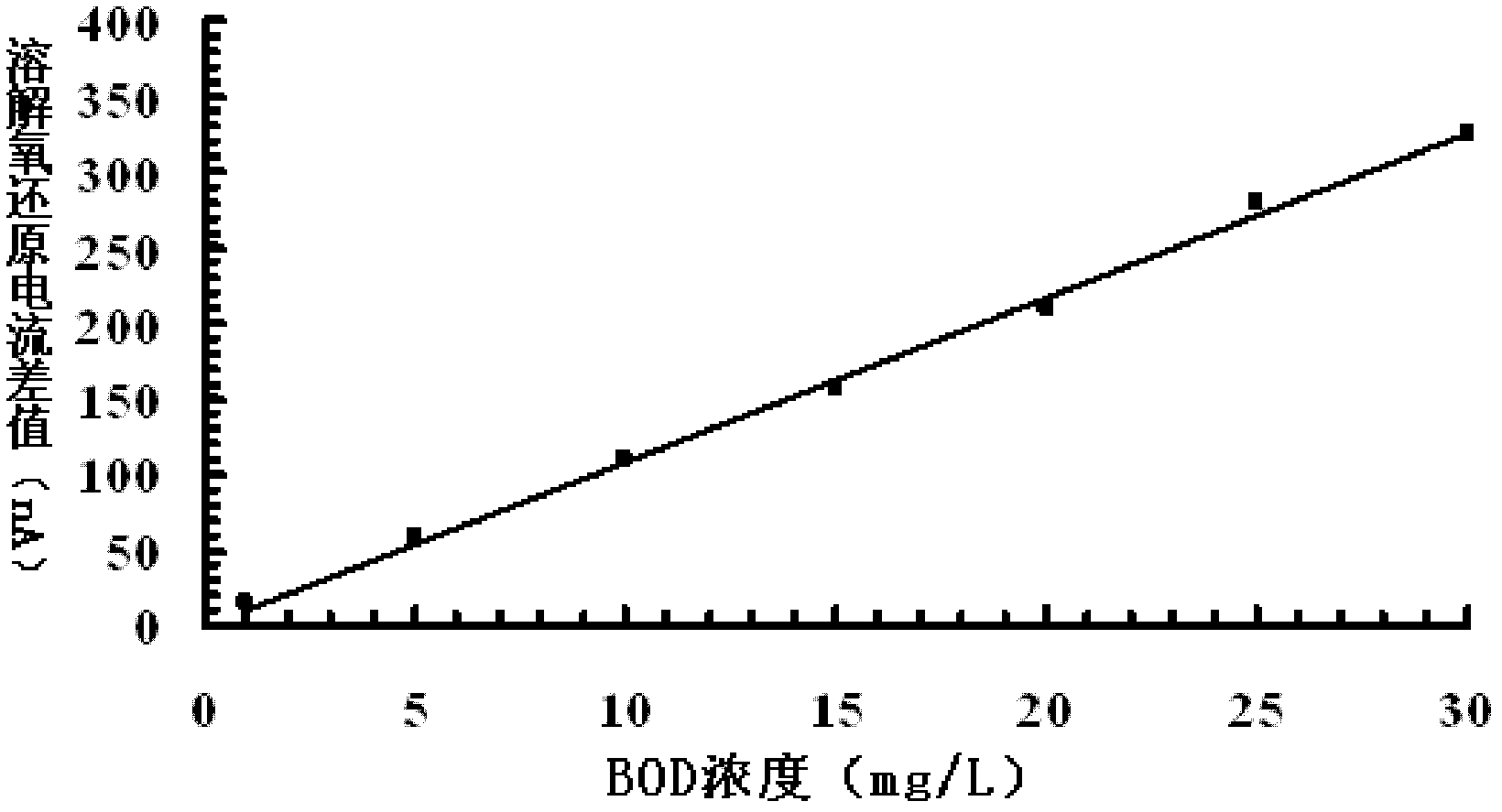

[0119] Dissolve 150mg of glucose and 150mg of glutamic acid in tap water and set the volume to 100mL to obtain a BOD concentration of 1980.0mg O 2 / L of the mother liquor of the glucose glutamate solution. The mother liquor is diluted with tap water to obta...

Embodiment 3

[0122] Turn on the constant temperature water bath 20 and adjust the temperature to 30°C. 300 mL of tap water was poured into the tap water container 15, and it was air-saturated at a rate of 3.0 L / min. Under the control of the peristaltic pump 9, the obtained air-saturated tap water flows through the second sampling tube 12, the solenoid valve 10 and the sampling tube 19 at a rate of 1.0 mL / min, reaches the reactor 8, and flows through the reactor 8. Finally, it reaches the surface of the oxygen electrode 5 . The electrochemical workstation 3 monitors the change of the oxygen electrode current, and when the oxygen electrode current is stable, the recorded dissolved oxygen reduction current is 538nA.

[0123] The water samples in the secondary sedimentation tank of Changchun No. 2 Sewage Treatment Plant were air-saturated at a rate of 3.0 L / min. Under the control of the peristaltic pump 9, the water sample in the actual water sample container 14 flows through the first sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com