Method for establishing energy coupling self-consistent model for laser penetration welding

A self-consistent model, energy coupling technology, applied in laser welding equipment, welding equipment, simulators and other directions, can solve problems such as deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

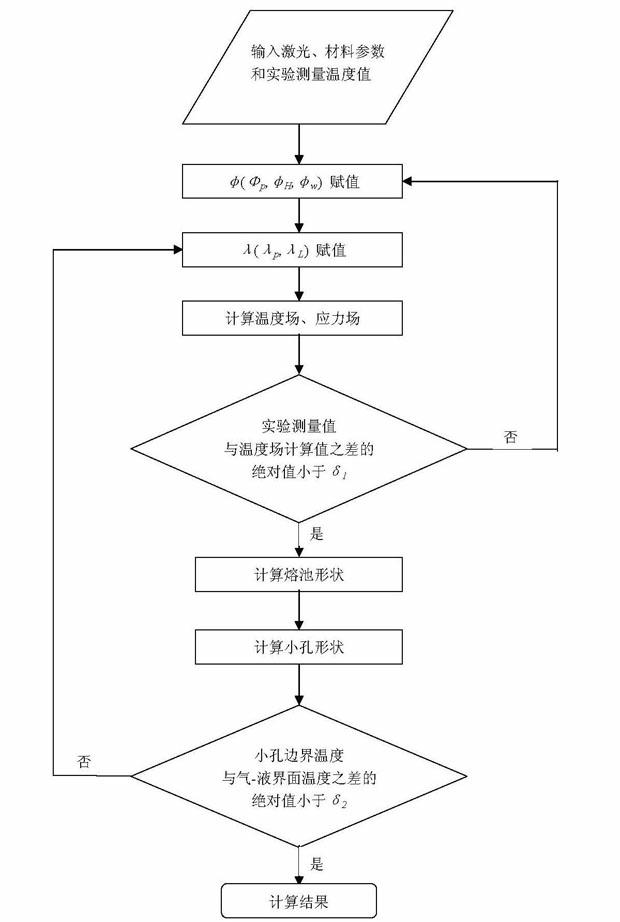

[0015] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

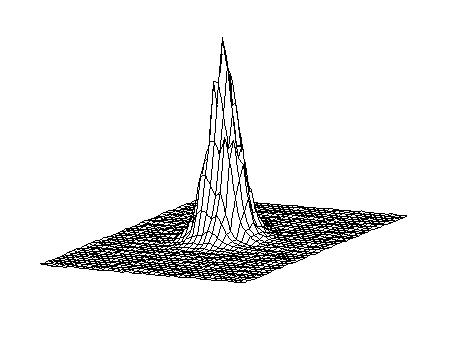

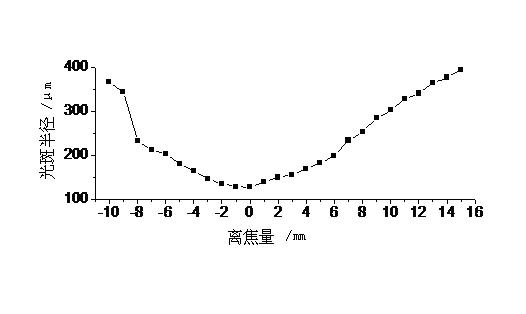

[0016] 1) Measure the power, power density, emission angle and spot diameter of the laser with relevant testing instruments, select a series of specific points in the molten pool and plasma area as the reference point temperature during the welding process, and measure and record these actual measured values and the temperature of the material eigenvalues of relevant physical properties; 2) calculated according to theory and combined with empirical formula φ ( Φ p ,φ H ,φ w ) value range, and set the initial value, and user-defined increment step size; 3) Calculate according to the empirical formula lambda ( lambda p ,λ L ) and set the initial value, and user-defined in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com