SiC-bipolar junction transistor (SiC-BJT) device for power integrated circuit and manufacturing method of SiC-BJT device

A technology of an integrated circuit and a manufacturing method, applied in the field of microelectronics, can solve the problems of large size and volume of the power module circuit, and achieve the effects of reducing the area size, reducing the interface electric field density, and improving the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

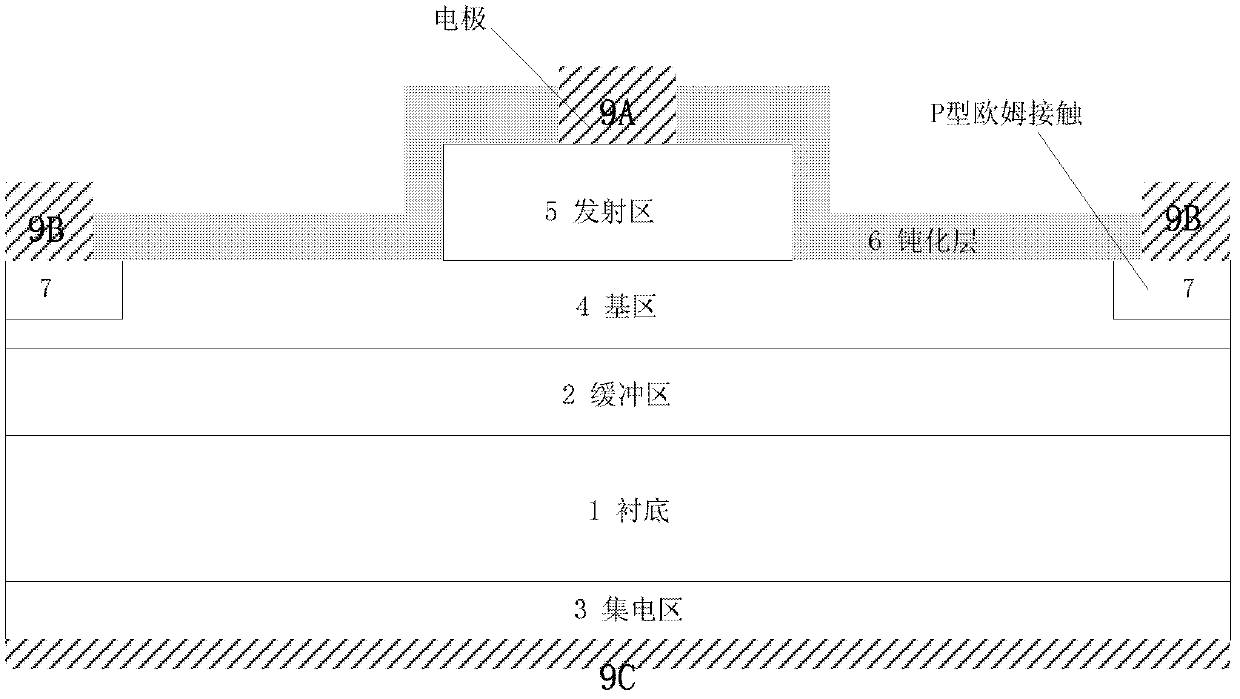

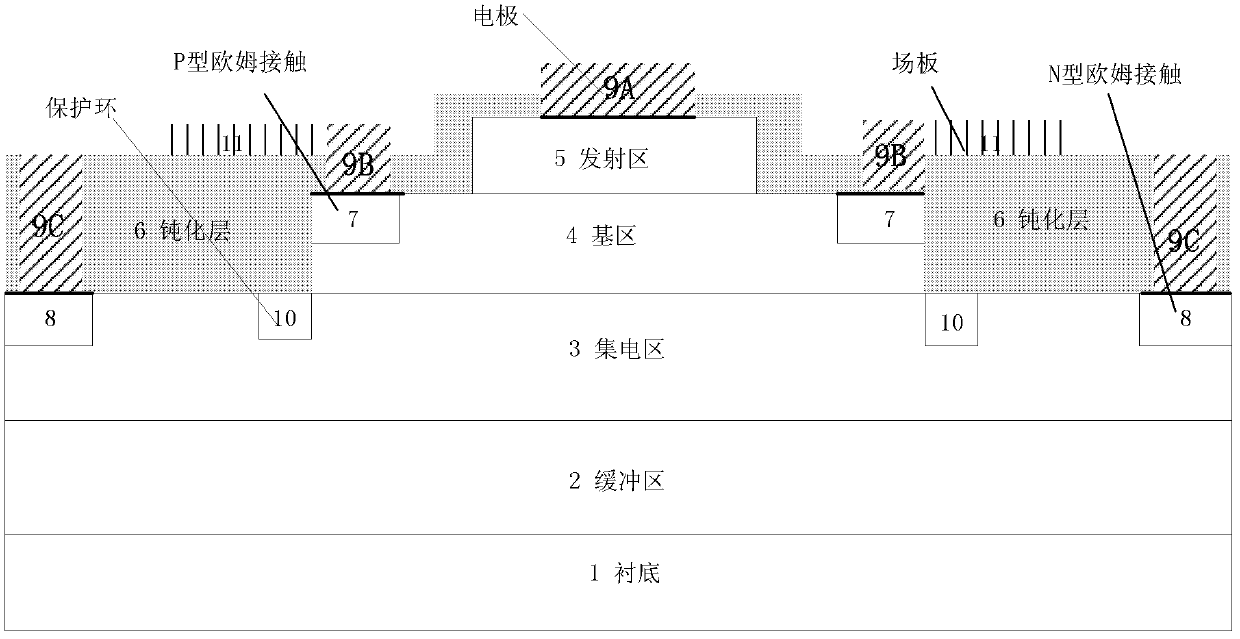

Embodiment 1

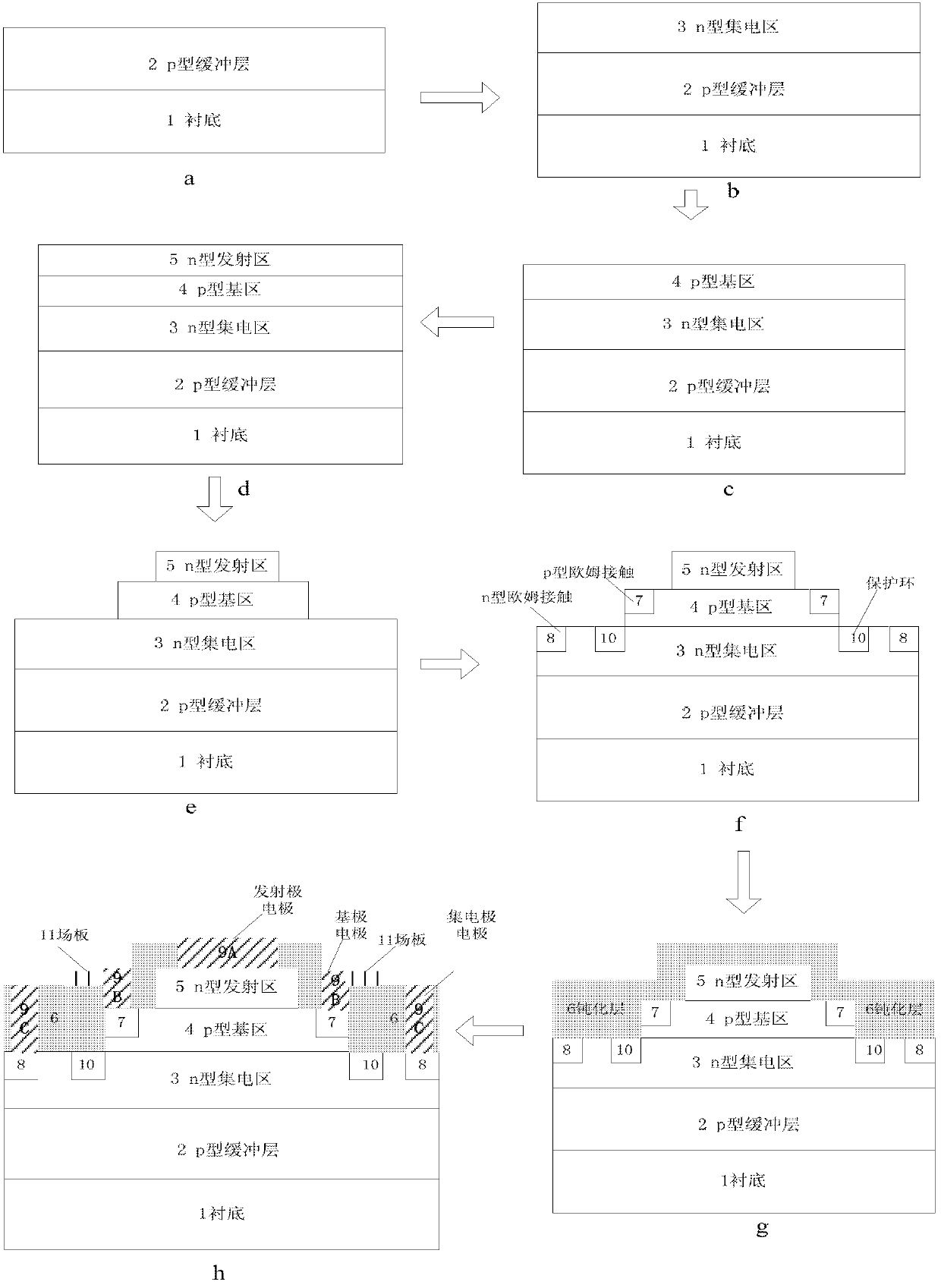

[0031] Step 1: Select a p-type SiC substrate, after cleaning, epitaxially grow a p-type buffer layer with a thickness of 2um on the p-type substrate, in which the aluminum doping concentration is 7×10 18 cm -3 ,Such as image 3 a.

[0032] Step 2: Epitaxially grow an n-type collector region with a thickness of 5um on the p-type buffer layer, in which the nitrogen doping concentration is 5×10 16 cm -3 ,Such as image 3 b.

[0033] Step 3: Epitaxially grow a p-type base region with a thickness of 1um on the n-type collector region, in which the aluminum doping concentration is 3×10 17 cm -3 ,Such as image 3 c.

[0034] Step 4: Epitaxially grow an n-type emitter region with a thickness of 1.2um on the p-type base region, where the nitrogen doping concentration is 2×10 19 cm -3 ,Such as image 3 d.

[0035] Step 5: Etch the mesa of the 1um emitter region from the uppermost n-type emitter region, and etch the mesa of the 0.8um base region from the p-type base region, s...

Embodiment 2

[0045] Step 1: Select an n-type SiC substrate, after cleaning, epitaxially grow a p-type buffer layer with a thickness of 5um on the n-type substrate, in which the aluminum doping concentration is 5×10 18 cm -3 ,Such as image 3 a.

[0046] Step 2: Epitaxially grow an n-type collector region with a thickness of 15um on the p-type buffer layer, wherein the nitrogen doping concentration is 5×10 15 cm -3 ,Such as image 3 b.

[0047] Step 3: Epitaxially grow a p-type base region with a thickness of 0.4um on the n-type collector region, in which the aluminum doping concentration is 8×10 17 cm -3 ,Such as image 3 c.

[0048] Step 4: Epitaxially grow an n-type emitter region with a thickness of 0.5um on the p-type base region, where the nitrogen doping concentration is 6×10 19 cm -3 ,Such as image 3 d.

[0049] Step 5: Etch the mesa of the 0.5um emitter region from the uppermost n-type emitter region, and etch the mesa of the 0.2um base region from the p-type base regi...

Embodiment 3

[0059] Step A: Select a p-type SiC substrate, after cleaning, epitaxially grow a p-type SiC buffer layer with a thickness of 4um and doped with aluminum ions on the p-type substrate, and its doping concentration is 3×10 18 cm -3 ,Such as image 3 a.

[0060] Step B: Epitaxially grow an n-type collector region with a thickness of 12um on the p-type buffer layer, wherein the nitrogen doping concentration is 2×10 16 cm -3 ,Such as image 3 b.

[0061] Step C: epitaxially grow a p-type base region with a thickness of 0.7um on the n-type collector region, wherein the aluminum doping concentration is 5×10 17 cm -3 ,Such as image 3 c.

[0062] Step D: Epitaxially grow an n-type emitter region with a thickness of 0.8um on the p-type base region, wherein the nitrogen doping concentration is 4×10 19 cm -3 ,Such as image 3 d.

[0063] Step E: Etch the mesa of the 0.8um emitter region from the uppermost n-type emitter region, and etch the mesa of the 0.6um base region from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com