Gas processing system

A gas processing system and gas processing technology, applied in the field of low-cost, high-maintenance gas processing system, and miniaturization, can solve the problems of high price and large-scale gas processing system, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

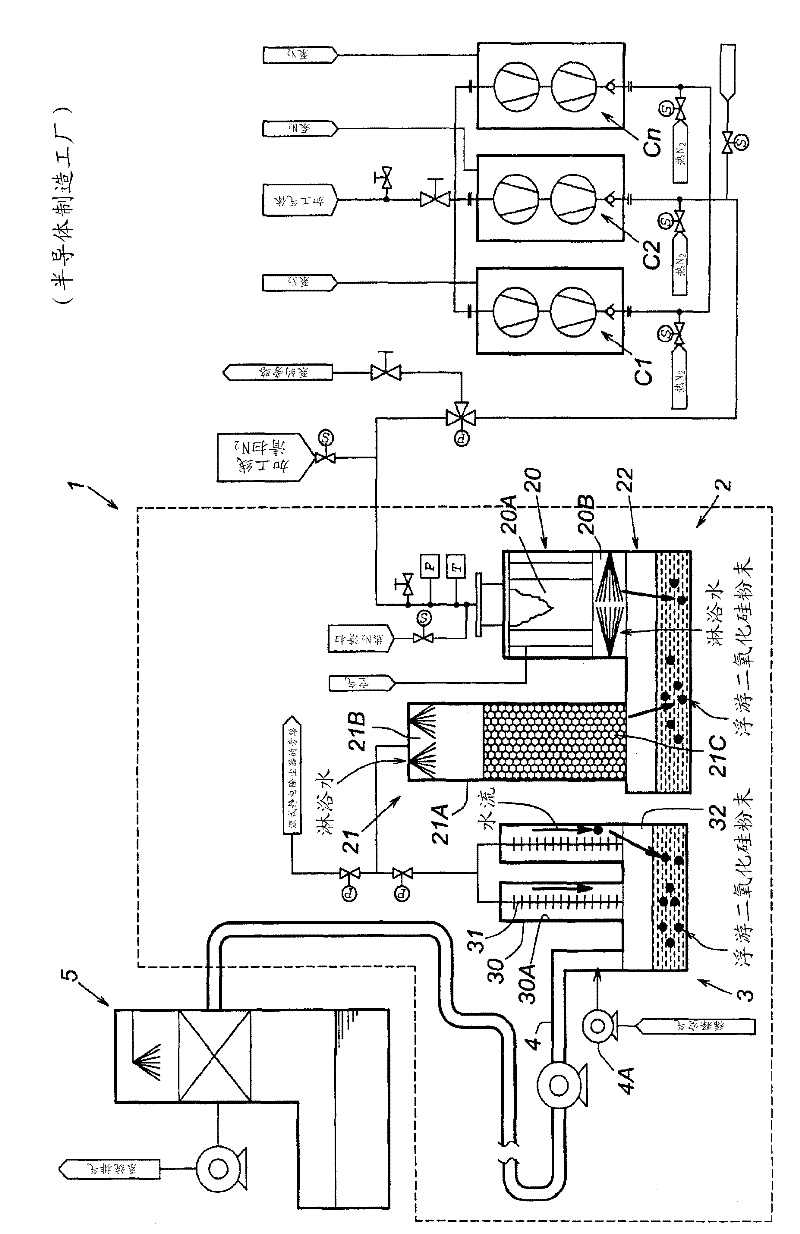

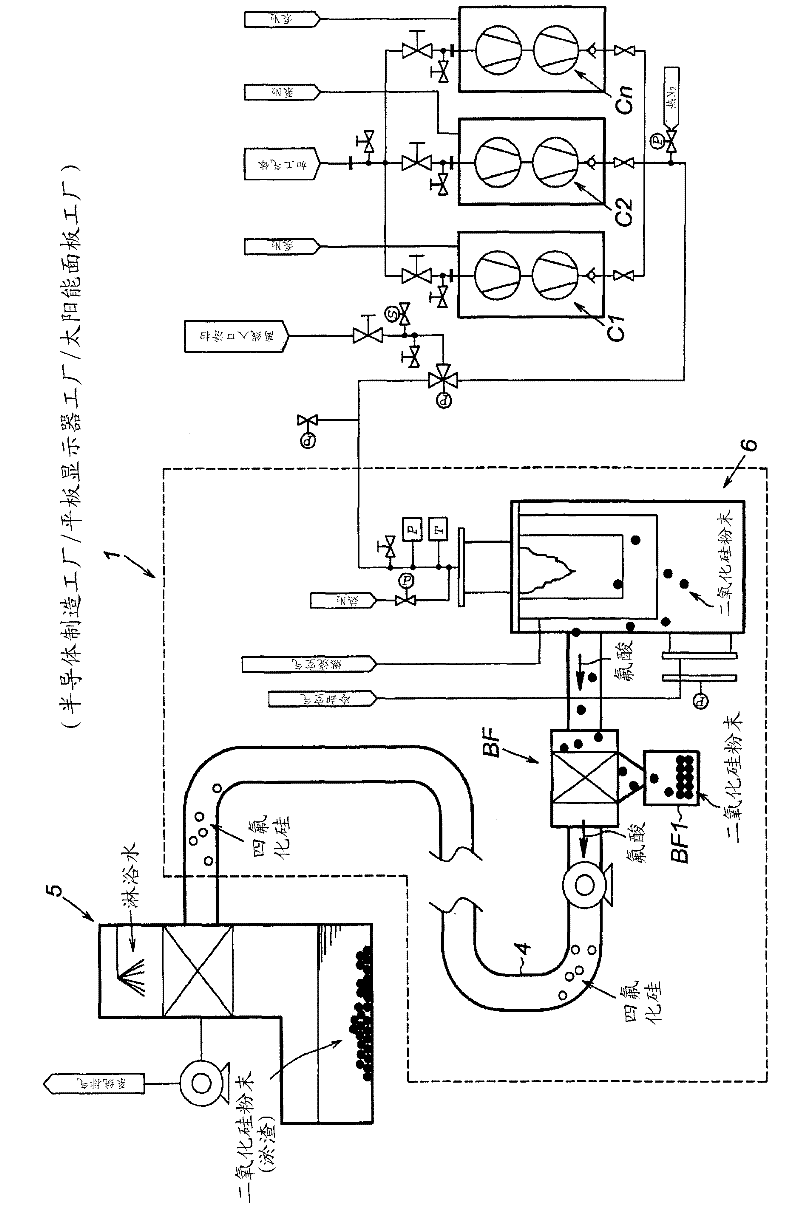

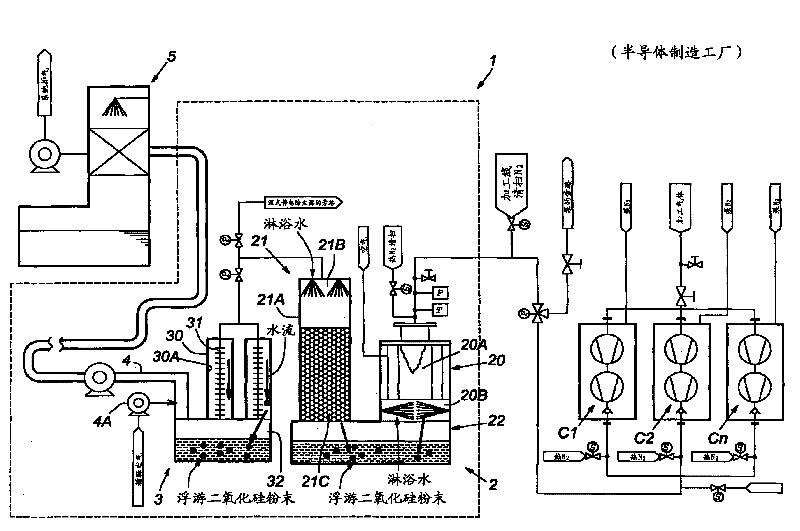

[0023] Refer to the attached Figure 1 The best mode for carrying out the present invention will be described in detail.

[0024] figure 1 It is a system configuration diagram of an example in which a gas processing system as an embodiment of the present invention is applied to a semiconductor manufacturing plant.

[0025] figure 1 In a semiconductor manufacturing plant, processes such as CVD (Chemical Vapor Deposition, Chemical Vapor Deposition), etching, etc. are performed in each sealed chamber C1, C2...Cn. Process gases such as silane used in these processes or gaseous substances produced by-products in the process are exhausted to the closed chambers C1, C2...Cn by unshown exhaust pumps connected to the closed chambers C1, C2...Cn external. Furthermore, the cleaning gas such as nitrogen trifluoride used in the plasma automatic cleaning of the closed chambers C1, C2...Cn is similarly exhausted to the outside of the closed chambers C1, C2...Cn. In this way, the gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com