Silymarin compound nanoparticle and preparation method thereof

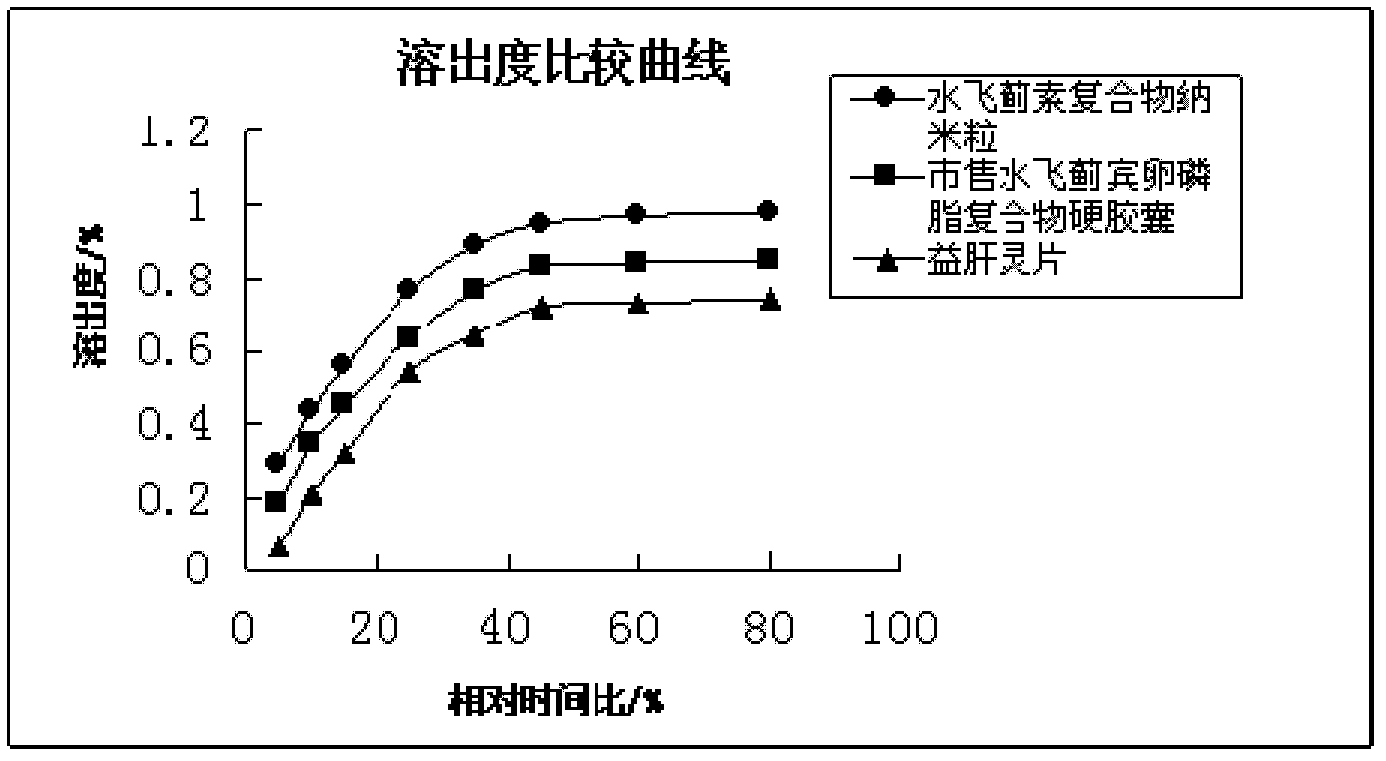

A technology of silymarin and compound, which is applied in the direction of drug combination, pharmaceutical formula, plant raw material, etc., can solve the problems of easy agglomeration between particles, difficult control of particle size, etc., and achieves high dissolution rate and controllable ultra-fine operation. , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing silymarin complex nanoparticles, comprising the following steps:

[0036] (1) Take 1Kg of silymarin, 0.5Kg of hypromellose phthalate and 1Kg of water and mix them uniformly, and mix them for 40 minutes with a twin-screw extruder at a screw speed of 400 rpm to obtain a silymarin solid dispersion;

[0037] (2) The silymarin solid dispersion is mixed with 3Kg of soybean lecithin, 2Kg of Benzaze 35 and 300Kg of ethanol to obtain an ethanol suspension;

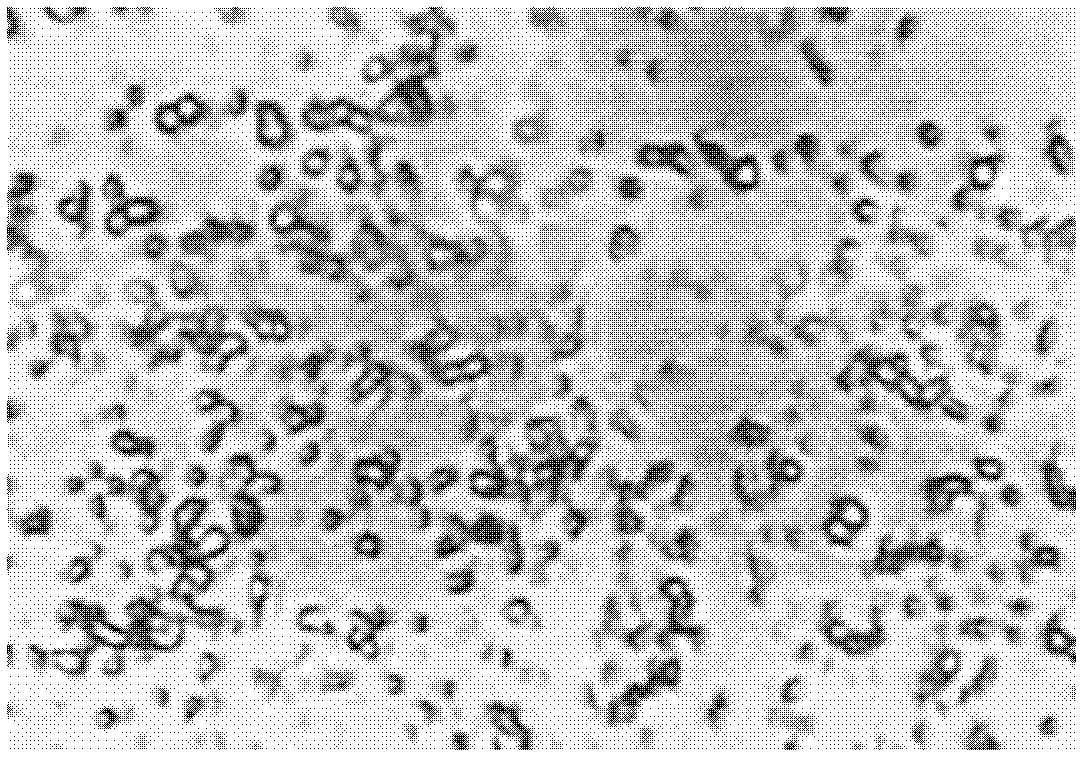

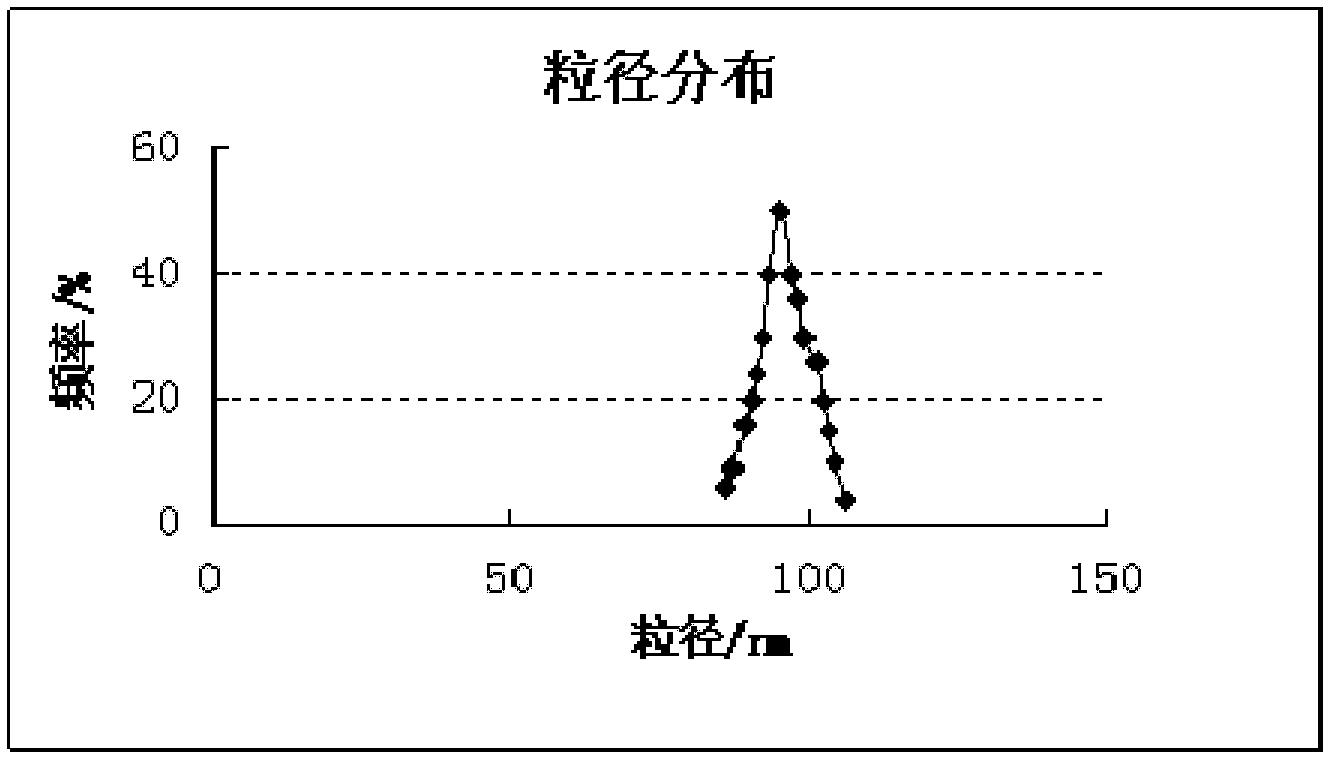

[0038] (3) passing the ethanol suspension through supercritical CO 2 Fluid equipment, at a temperature of 40°C, a pressure of 20MPa, CO 2 The flow rate is 10L / min, the solution flow rate is 1.2ml / min, and the nozzle diameter is 0.1mm, and the supercritical fluid anti-solvent technology is used to obtain silymarin composite nanoparticles, and the obtained composite nanoparticles have a particle size of 86nm-106nm. In view figure 1 -Figure 4.

Embodiment 2

[0040] A method for preparing silymarin complex nanoparticles, comprising the following steps:

[0041] (1) Take 1Kg of silymarin, 0.2Kg of hypromellose phthalate and 2Kg of water and mix them evenly, and mix them for 60 minutes with a twin-screw extruder at a screw speed of 300 rpm to obtain a silymarin solid dispersion;

[0042] (2) The silymarin solid dispersion is mixed with 1Kg of soybean lecithin, 3Kg of Benzaze 35 and 300Kg of ethanol to obtain an ethanol suspension;

[0043] (3) passing the ethanol suspension through supercritical CO 2 Fluid equipment, at a temperature of 35°C, a pressure of 15MPa, CO 2 The flow rate is 5L / min, the solution flow rate is 0.5ml / min, and the nozzle diameter is 0.08mm, and the supercritical fluid anti-solvent technology is used to obtain silymarin composite nanoparticles, and the obtained composite nanoparticles have a particle size of 89nm-110nm.

Embodiment 3

[0045] A method for preparing silymarin complex nanoparticles, comprising the following steps:

[0046] (1) Get 1Kg of silymarin, 0.4Kg of hypromellose phthalate and 0.5Kg of water and mix them evenly, and mix them for 20min with a twin-screw extruder at a screw speed of 500rpm to obtain a silymarin solid dispersion ;

[0047] (2) Mix the silymarin solid dispersion with 3Kg of egg yolk lecithin, 1Kg of Benzaze 35 and 500Kg of ethanol to obtain an ethanol suspension;

[0048] (3) passing the ethanol suspension through supercritical CO 2 Fluid equipment, at a temperature of 40°C, a pressure of 20MPa, CO 2The flow rate is 10L / min, the solution flow rate is 1.2ml / min, and the nozzle diameter is 0.1mm, and the supercritical fluid anti-solvent technology is used to obtain silymarin composite nanoparticles, and the obtained composite nanoparticles have a particle size of 93nm-115nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com