Preparation of palygorskite clay/plant stalk composite adsorbent and application of composite adsorbent in treating printing and dyeing wastewater

A technology of palygorskite clay and plant straw, applied in the direction of adsorption of water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of secondary pollution of adsorbents, air pollution, poor effect, etc., and achieve enhanced adsorption capacity and adsorption speed, improving purification capacity and efficiency, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

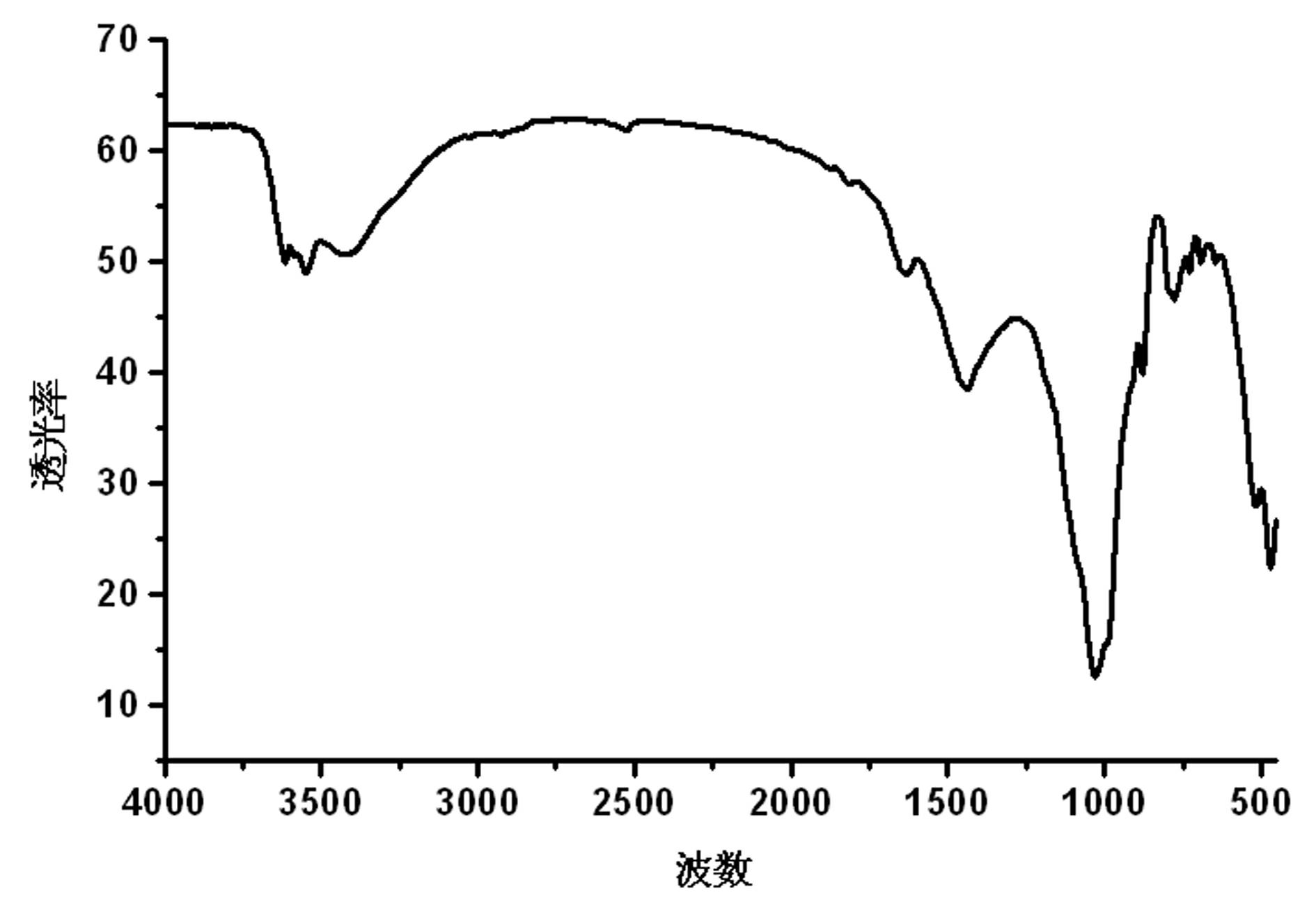

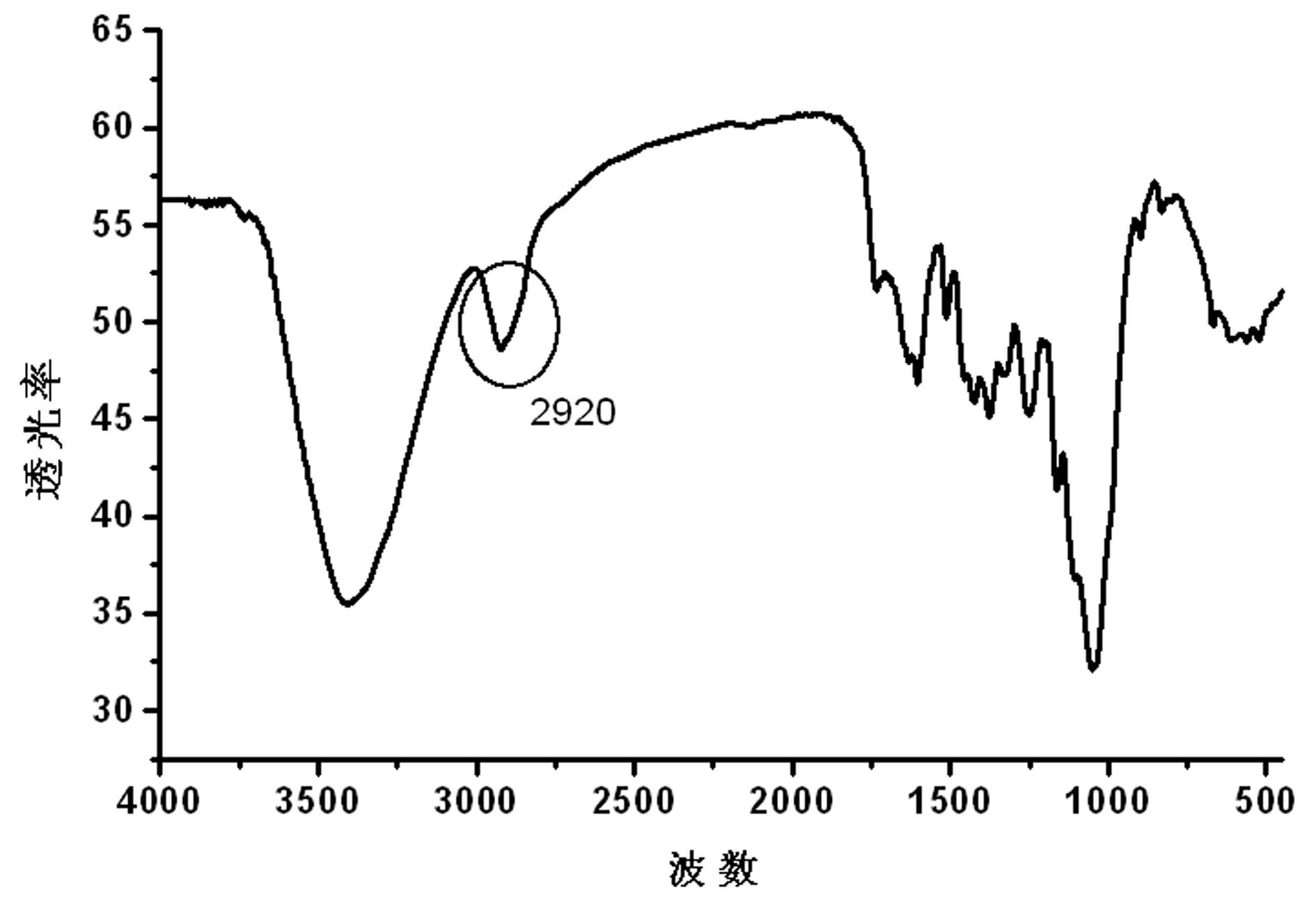

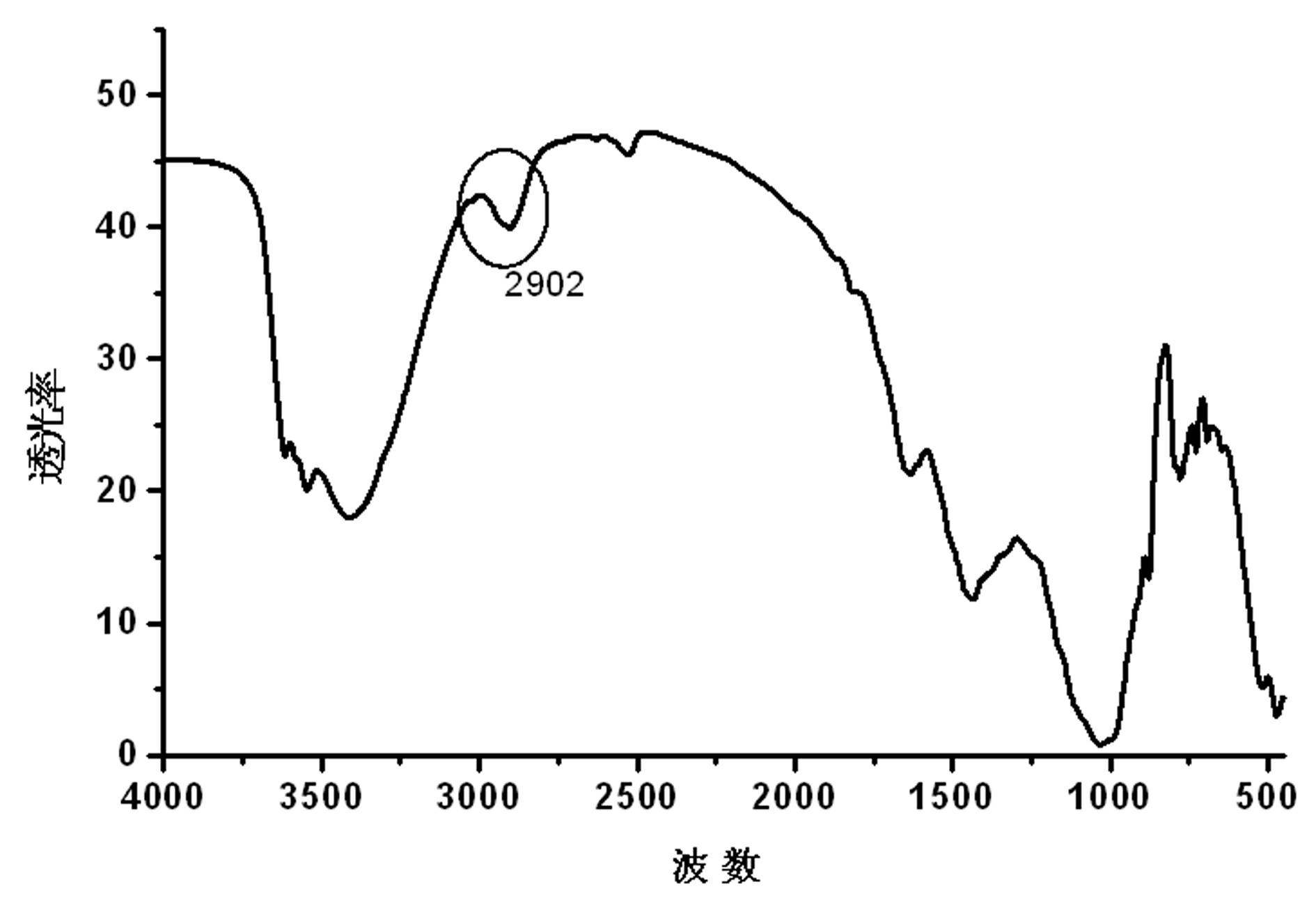

[0030] Preparation of adsorbent: crush palygorskite clay raw ore and waste plant straw to 100-300 mesh respectively, add them to the rotary autoclave at a mass ratio of 1:0.5 after drying, and use distilled water to prepare a total mass concentration of 10% The solution was stirred and hydrothermally reacted at 100°C for 1 h, cooled, filtered, and dried to obtain palygorskite clay / plant straw composite adsorbent.

[0031] Adsorption performance test: the methylene blue was formulated into a 350mg / L solution, and the adsorption test was carried out by using the composite adsorbent prepared by the present invention. Test conditions: solid-liquid ratio 30, temperature: 10°C, pH value 9, adsorption time 1.5h, adsorption rate 99%.

Embodiment 2

[0033]Preparation of adsorbent: crush palygorskite clay raw ore and waste plant straw to 100-300 mesh respectively, add them to the rotary autoclave at a mass ratio of 1:1 after drying, and use distilled water to prepare a total mass concentration of 10% The solution was stirred and hydrothermally reacted at 110°C for 1.5h, cooled, filtered, and dried to obtain palygorskite clay / plant straw composite adsorbent.

[0034] Adsorption performance test: Methyl orange was formulated into a 200mg / L solution, and the adsorption test was carried out by using the composite adsorbent prepared by the present invention. Test conditions: solid-liquid ratio 6, temperature: 10°C, pH value 3, adsorption time 0.1h, adsorption rate 98%.

Embodiment 3

[0036] Preparation of adsorbent: crush palygorskite clay raw ore and waste plant straw to 100-300 mesh respectively, add them to the rotary autoclave at a mass ratio of 1:1.5 after drying, and use distilled water to prepare a total mass concentration of 20% The solution was stirred and hydrothermally reacted at 120°C for 2 hours, cooled, filtered, and dried to obtain palygorskite clay / plant straw composite adsorbent.

[0037] Adsorption performance test: the methylene blue was formulated into a 200mg / L solution, and the adsorption test was carried out by using the composite adsorbent prepared by the present invention. Test conditions: solid-liquid ratio 18, temperature: 20°C, pH value 7, adsorption time 2.0h, adsorption rate 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com