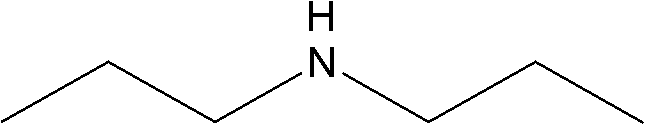

Method for combining di-n-propylamine through n-propylamine disproportionated reaction and used catalyst

A technology of di-n-propylamine and catalyst, which is applied in the field of synthesis of chemical intermediate-di-n-propylamine, can solve the problem of low selectivity of di-n-propylamine, and achieve the effects of high selectivity, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, a kind of preparation method of the supported catalyst for synthesizing di-n-propylamine, carry out the following steps successively:

[0048] 1), initial roasting:

[0049] Gamma-alumina (γ-Al 2 O 3 ) into the muffle furnace at 430~470℃ for 3h and then at 600~650℃ for 6h; γ-Al after calcination is obtained 2 O 3 ;

[0050] The specific surface area of γ-alumina after calcination is 200-220m 2 g -1 , the pore size is 13.5-14.0 nm; the particle diameter remains unchanged;

[0051] 2), γ-Al after the roasting of step 1) gained 2 O 3 Immerse in water for 36 hours, and then measure the volume reduced by water, so as to obtain γ-Al after calcination 2 O 3 The pore volume density of 0.85ml / g;

[0052] 3), the first impregnation:

[0053] 43.1g of nickel nitrate solid, 20.3g of copper nitrate solid, 2.0g of zinc nitrate solid and 5.9g of ruthenium nitrate solid (all containing no crystal water) are made up to 117ml with water (such as distilled wate...

Embodiment 2

[0062] Embodiment 2, a kind of production method of di-n-propylamine, step is as follows:

[0063] 1), the prepared supported catalyst (obtained in Example 1) is activated:

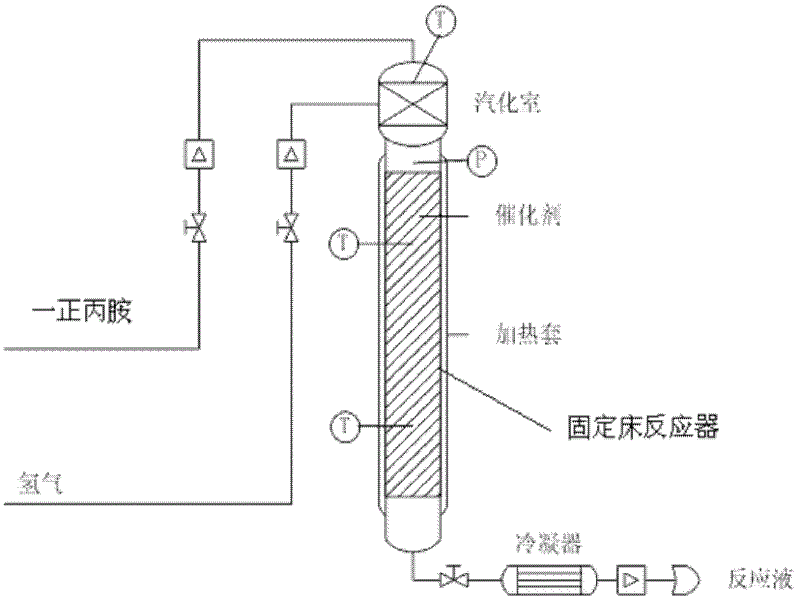

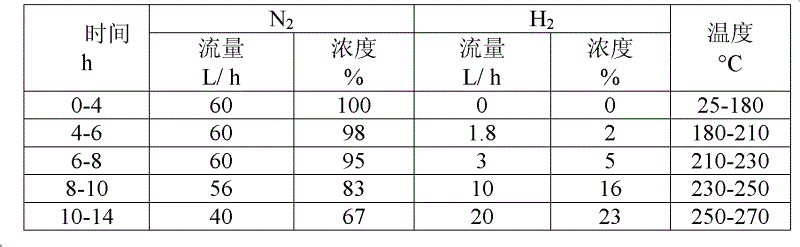

[0064] ①. The supported catalyst is preliminarily activated. The ventilation time, ventilation flow rate and heating temperature in different activation time periods are shown in Table 1 above; this step can be carried out outside the fixed bed reactor, or by using Fixed bed reactor (but need to add N 2 connecting pipes).

[0065] 2. Load the preliminarily activated supported catalyst into the fixed bed reactor, and reactivate it at 160-250 ° C (for example, 240 ° C) under the action of hydrogen until the activation is completed (that is, there is no condensed water in the lower part of the fixed bed reactor). produced); the supported catalyst after activation was obtained.

[0066] 2), place one-n-propylamine 23.6g (0.4mol) in the raw material tank, and after the preheater (that is, the vaporization c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com