Method of producing steel wire shots conforming to PSPC with quenching crushing method

A steel wire and crusher technology, which is applied in the field of metal abrasive manufacturing technology, can solve the problems that the fluidity cannot meet the requirements of use, the fluidity cannot meet the requirements of sandblasting, the contradiction between the service life and the fluidity, etc., and achieves low production costs and finished products. The effect of improving the rate and good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A method of utilizing quenching and crushing method to produce PCPC steel wire shot is characterized in that: comprising the following steps:

[0026] 1. Choose tire steel wire (the material is 72A) or steel wire rope (the material is 65M or 72A) as the material. According to the theory of heat treatment, these two steels are heated to 800-850 ° C and quickly quenched in cold water. Brittleness, in our experiments, bundles of dozens of wires can be easily broken with both hands.

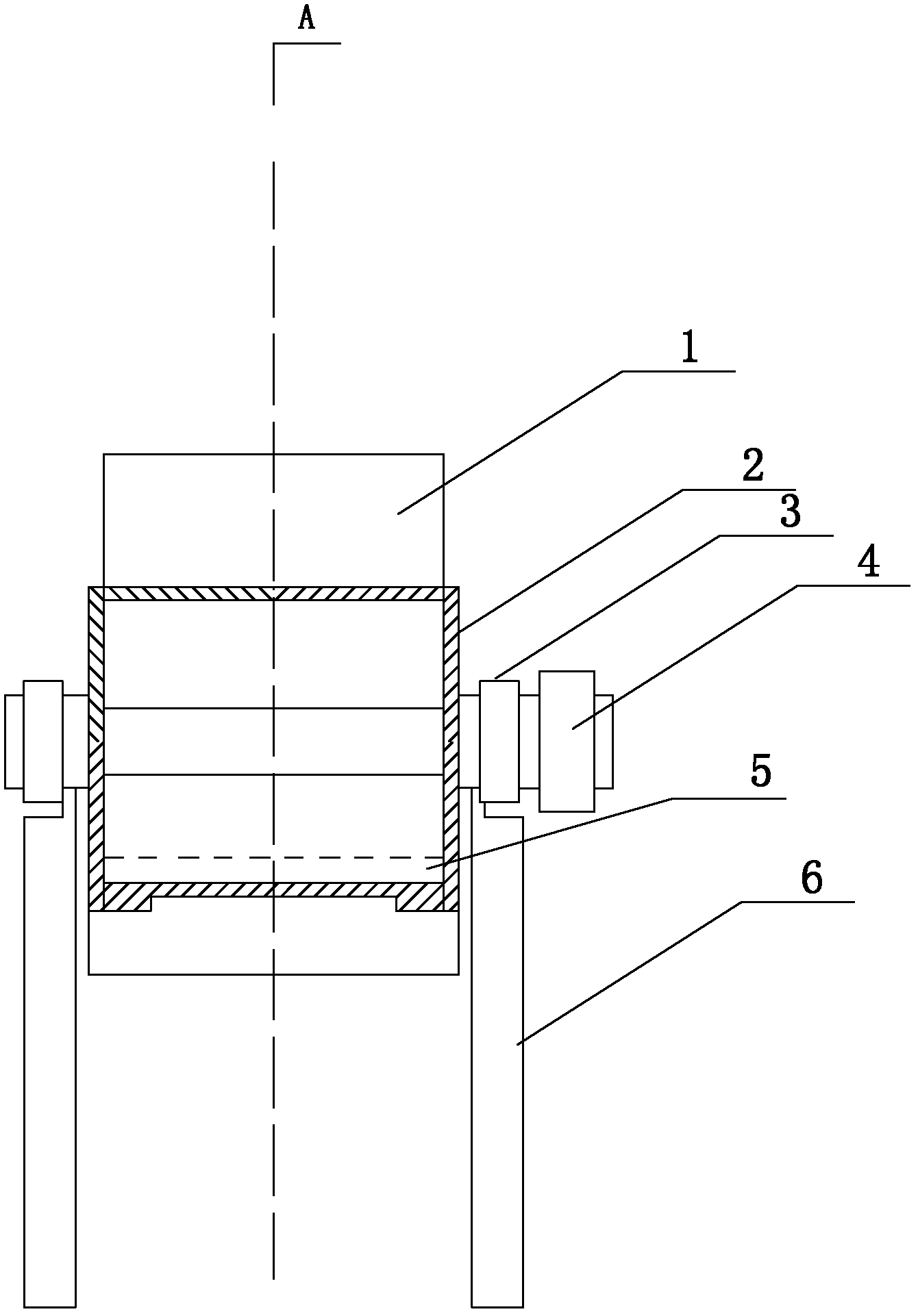

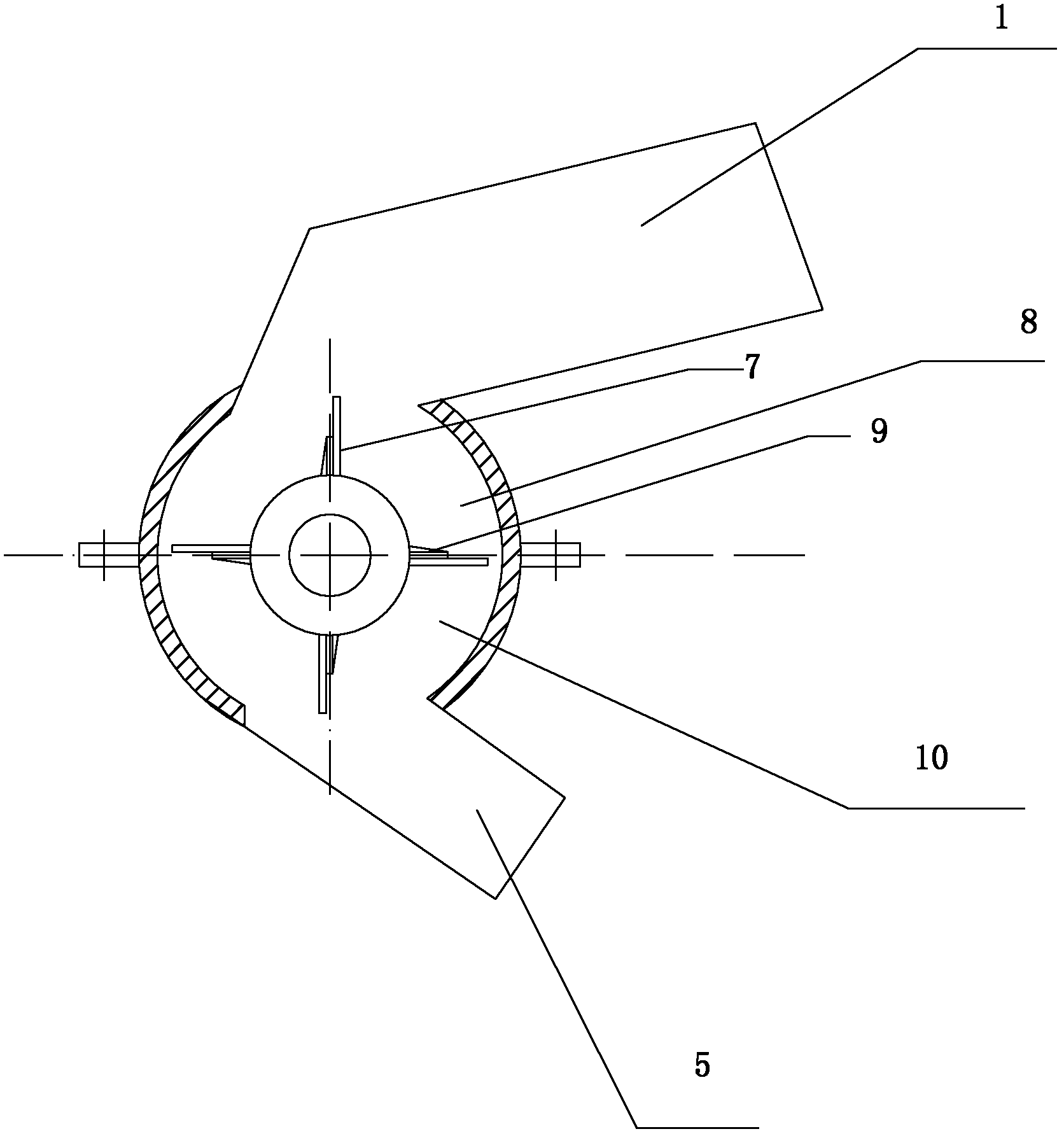

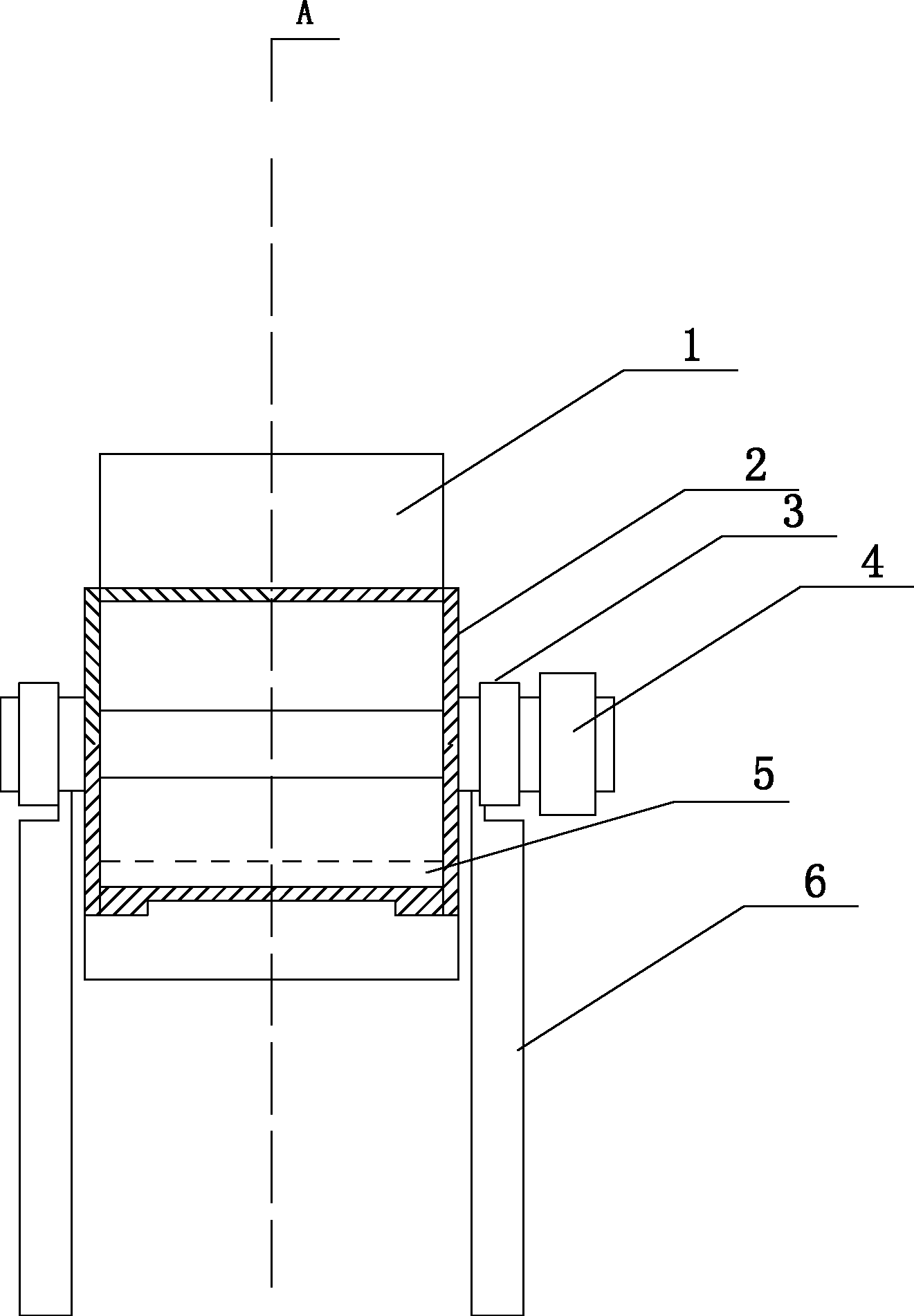

[0027] 3. Put the quenched steel wire into the bottomless grinder (see figure 1 ,See figure 2 ) for primary crushing, and the segment length after crushing is less than 5mm.

[0028] 4. The steel wire after primary crushing is placed on the crusher for secondary crushing, and the length of the segment after crushing is less than 3mm.

[0029] 5. Put the steel wire after secondary crushing on the special projecting machine (CN201592393U) for about 5 minutes. When most of the steel shots are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com