Method for preparing multiphase fiber based on microfluidic-electrostatic spinning technology

An electrospinning technology and microfluidic technology, applied in the direction of nanotechnology, fiber treatment, nanotechnology, etc. for materials and surface science, can solve the problems of difficult preparation of multi-phase micro-nano fibers, and achieve easy structure adjustment, Low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

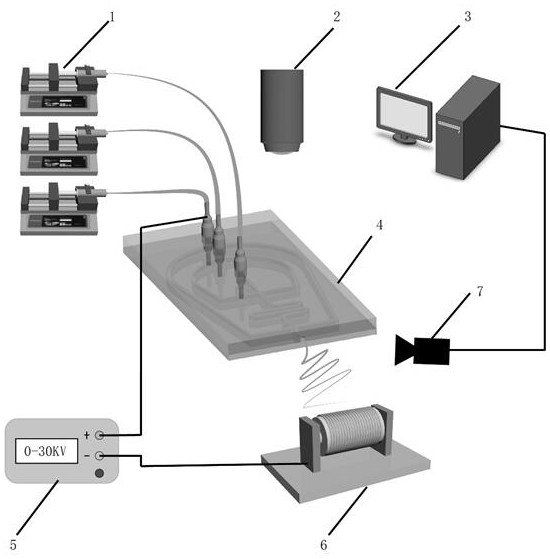

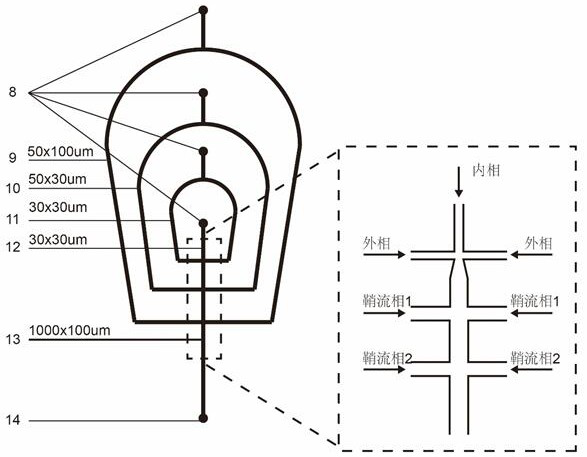

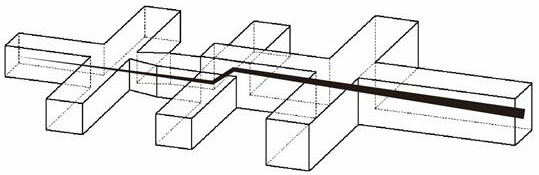

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of discrete structured multi-phase micro-nano fibers based on PDMS microfluidic chip.

[0042] This example provides a method for preparing a discrete-type intelligent constant-temperature multi-phase micro-nano fiber:

[0043] As a non-toxic and harmless phase change material, n-hexadecane is widely used in various engineering fields. In this embodiment, by encapsulating n-hexadecane in PVA nanofibers, the problem of leakage of n-hexadecane when it is transformed into a liquid state is solved.

[0044]First, sodium dodecyl sulfate (SDS) was added to deionized water at a rate of 1mg / ml as a solvent at room temperature, and then polyvinyl alcohol (PVA) was added to the solvent to prepare PVA solutions with mass fractions of 10wt% and 6wt%. , and then stirred with an electromagnetic stirrer for 24 hours under the condition of heating in a water bath at 70° C., and after it was fully dissolved, an external phase solution was obtained for future use. ...

Embodiment 2

[0048] Example 2 Preparation of continuous structured multi-phase micro-nano fibers based on glass tube microfluidic chip.

[0049] This example provides a continuous structure intelligent constant temperature multi-phase micro-nano fiber preparation method:

[0050] As a non-toxic and harmless phase change material, trimethylolethane is widely used in various engineering fields. In this example, by encapsulating 1,1,1-trimethylolethane in polycaprolactone (PCL) nanofibers, the problem of trimethylolethane leakage when it turns into a liquid state is solved.

[0051] First, 1 g of PCL was added to 9 g of dimethyl carbonate (DMC) at room temperature to prepare a 10 wt % PCL solution. Then stir with an electromagnetic stirrer for 24 hours under the condition of heating in a water bath at 50°C. After it is fully dissolved, the external phase solution is obtained for use, and coumarin 6 is added as a fluorescent indicator. At room temperature, 5 g of trimethylolethane was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com