Preparing-molding method and performance testing method of zinc-bromine flow battery polar plate

A technology of zinc-bromine flow battery and forming method, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of zinc-bromine battery plate conductivity, electrolyte corrosion resistance and swelling properties are not ideal, so as to facilitate electronic conduction , defect reduction, and the effect of reducing the chance of corroding the base material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 of the present invention: the preparation molding method of zinc-bromine flow battery pole plate, comprises the following steps:

[0030] S1, calculated in parts by weight, take 5 parts of multi-walled carbon nanotubes, 8 parts of conductive carbon black and 6 parts of graphite for compounding and clockwise stirring, the stirring time is 30 minutes, wherein the morphology of carbon nanotubes under a scanning electron microscope The schematic diagram and the schematic diagram of the morphology under the transmission electron microscope are shown in figure 1 and figure 2 shown;

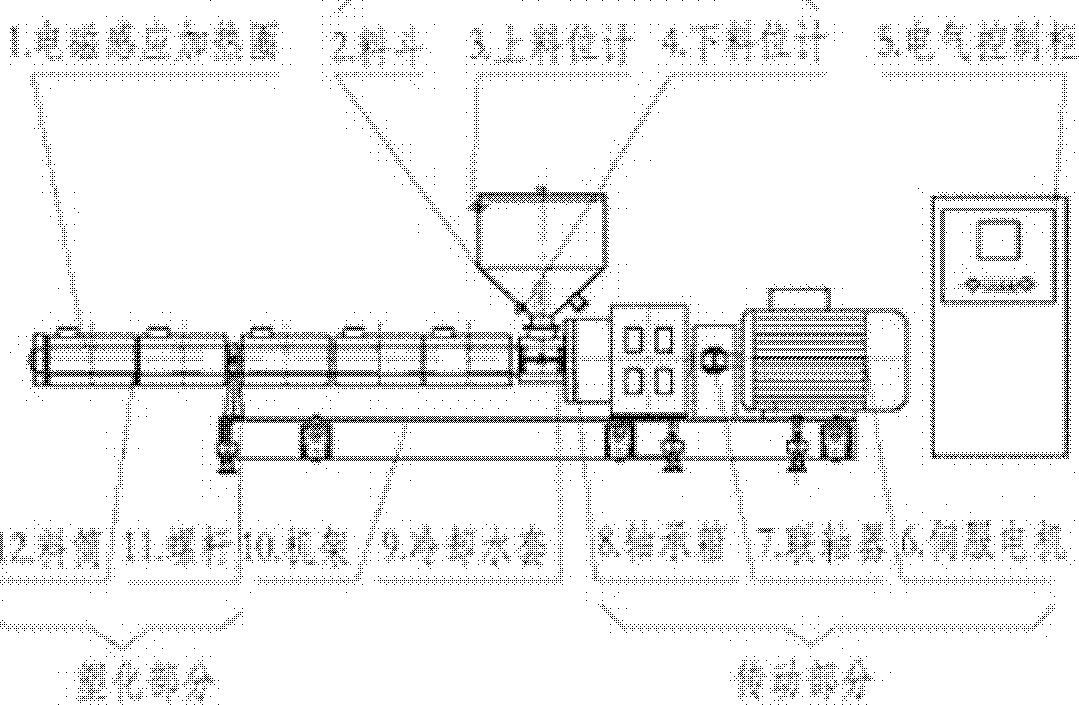

[0031] S2, calculated in parts by weight, take 80 parts of PE raw materials and add them to the above-mentioned mixture for secondary stirring. The stirring time is 30 minutes, wherein the PE raw materials can be a mixture of LLDPE and HDPE, and the content ratio of the two is 1: 2; the stirring is conventional stirring, which can be clockwise stirring, wherein the schematic diagr...

Embodiment 2

[0034] Embodiment 2 of the present invention: the preparation molding method of zinc-bromine flow battery pole plate, comprises the following steps:

[0035] S1, calculated in parts by weight, take 8 parts of multi-walled carbon nanotubes, 5 parts of conductive carbon black and 5 parts of graphite for compounding and conventional stirring. The stirring time is 30 minutes. The schematic diagram of the morphology of carbon nanotubes under a scanning electron microscope and the schematic morphology under the transmission electron microscope as figure 1 and figure 2 shown;

[0036] S2, calculated in parts by weight, take 70 parts of PE raw materials and add them to the above-mentioned mixture for secondary stirring, the stirring time is 30 minutes, wherein the PE raw materials can be a mixture of LLDPE and HDPE, and the content ratio of the two is 1: The stirring described in 2 is conventional stirring, which can be clockwise stirring, wherein the schematic diagram of the morph...

Embodiment 3

[0039] Embodiment 3 of the present invention: a method for preparing and forming a zinc-bromine flow battery pole plate, comprising the following steps:

[0040] S1, calculated by weight, take 4 parts of multi-walled carbon nanotubes, 10 parts of conductive carbon black and 10 parts of graphite for compounding and conventional stirring. The stirring time is 30 minutes. The schematic diagram of the morphology of carbon nanotubes under a scanning electron microscope and the schematic morphology under the transmission electron microscope as figure 1 and figure 2 shown;

[0041] S2, calculated in parts by weight, take 76 parts of PE raw materials and add them to the above-mentioned mixture for secondary stirring, the stirring time is 30 minutes, wherein the PE raw materials can be a mixture of LLDPE and HDPE, and the content ratio of the two is 1: The stirring described in 2 is conventional stirring, which can be clockwise stirring, wherein the schematic diagram of the morpholo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com