Seal-free paper-aluminum compound material sterile brick packaging machine

A composite material and aseptic brick technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of high equipment cost and maintenance cost, large construction cost, increased production cost, etc., to prevent light and oxygen. Intrusion, preventing direct contact, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

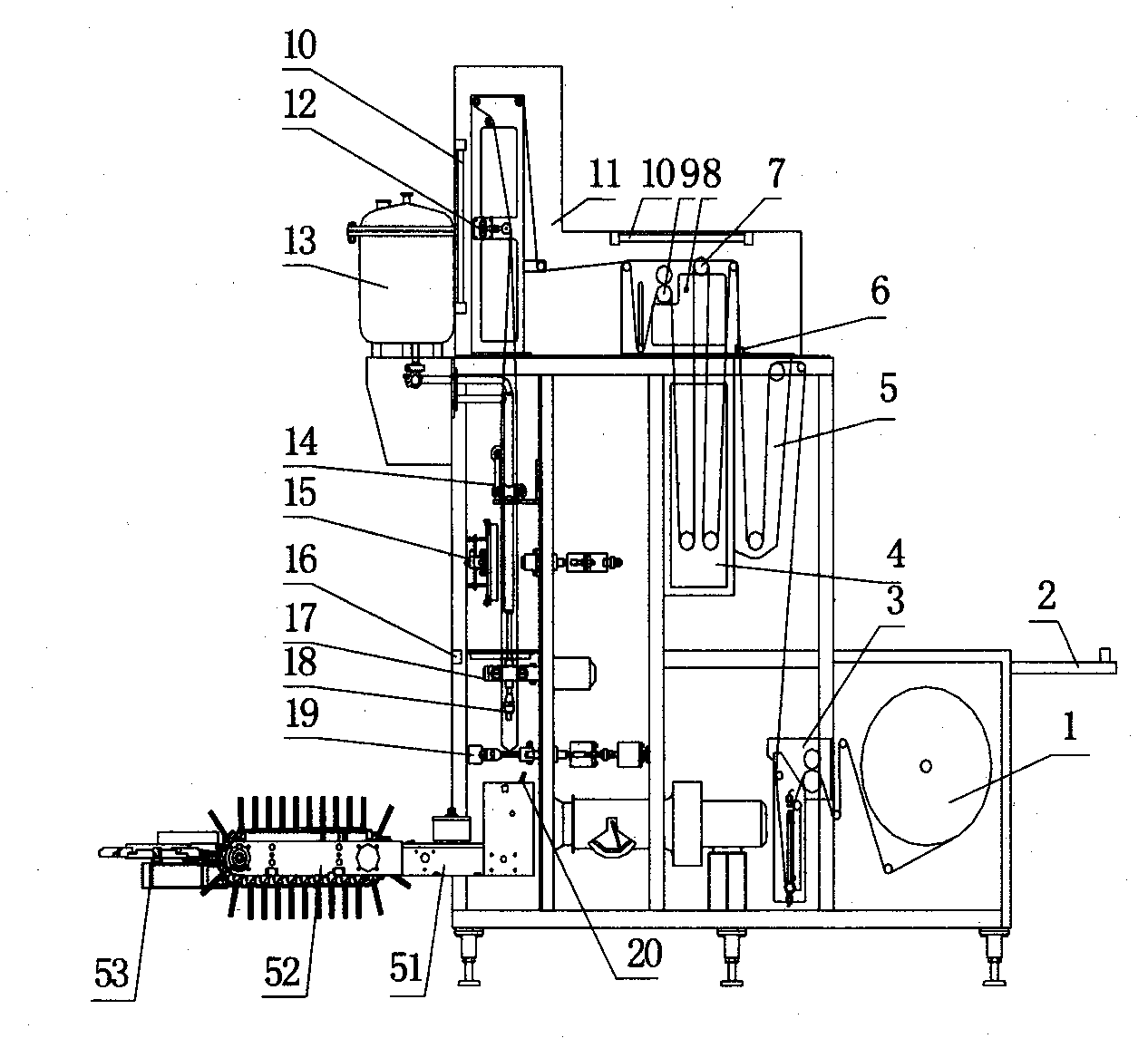

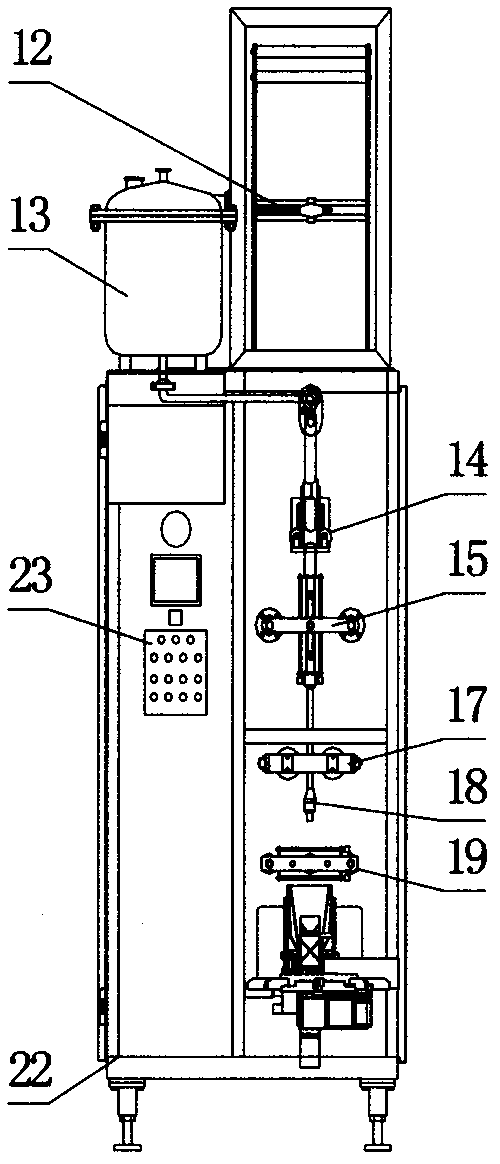

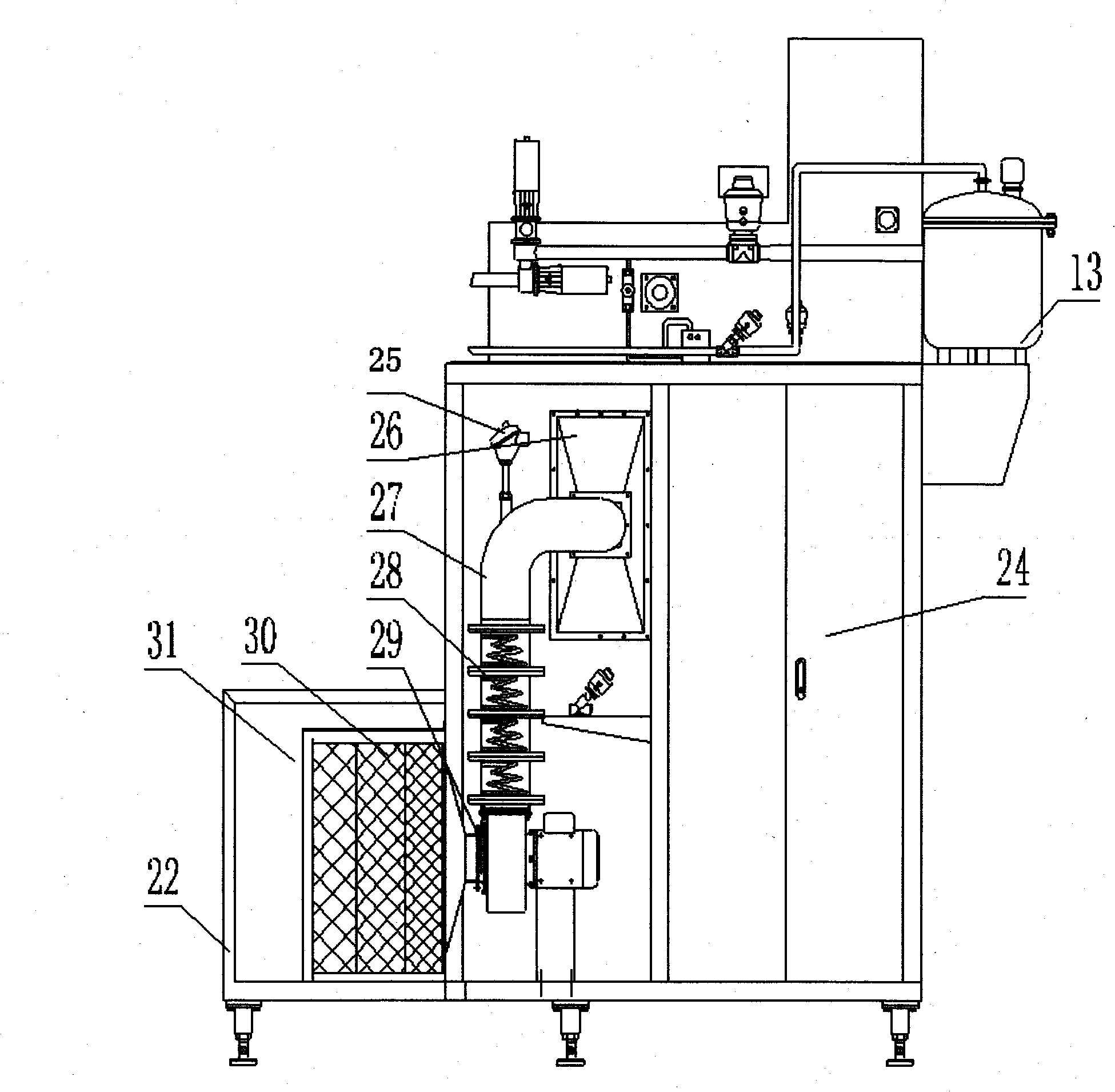

[0039] Such as Figure 1 to Figure 3 As shown, it is a structural schematic diagram of the non-sealed paper aluminum composite material aseptic brick packaging machine disclosed in this embodiment, including a paper roll 1, a paper receiving mechanism 2, a paper releasing mechanism 3, an air inlet 4, a hydrogen peroxide tank 5, and a hydrogen peroxide scraper 6. Guide roller 7, atomizing nozzle 8, paper feeding mechanism 9, ultraviolet lamp 10, sterile room 11, forming correction device 12, metering tank 13, forming wheel assembly 14, longitudinal sealing device 15, mark detection 16, paper feeding Traction device 17, filling pipe 18, transverse sealing and cutting device 19, package discharge chute 20, exhaust device 21, machine body 22, operation panel 23, electrical control box 24, sterile hot air treatment system 31, package d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com