Production method for aluminum-doped zinc oxide nanometer material

A technology of aluminum-doped zinc oxide and nanomaterials, which is applied in the field of production of porous grid rod-shaped self-assembled aluminum-doped zinc oxide nanomaterials, which can solve complex operations, need for reaction equipment, and limit the large-scale application of zinc oxide nanomaterials, etc. problems, to achieve the effect of high specific surface area and developed pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

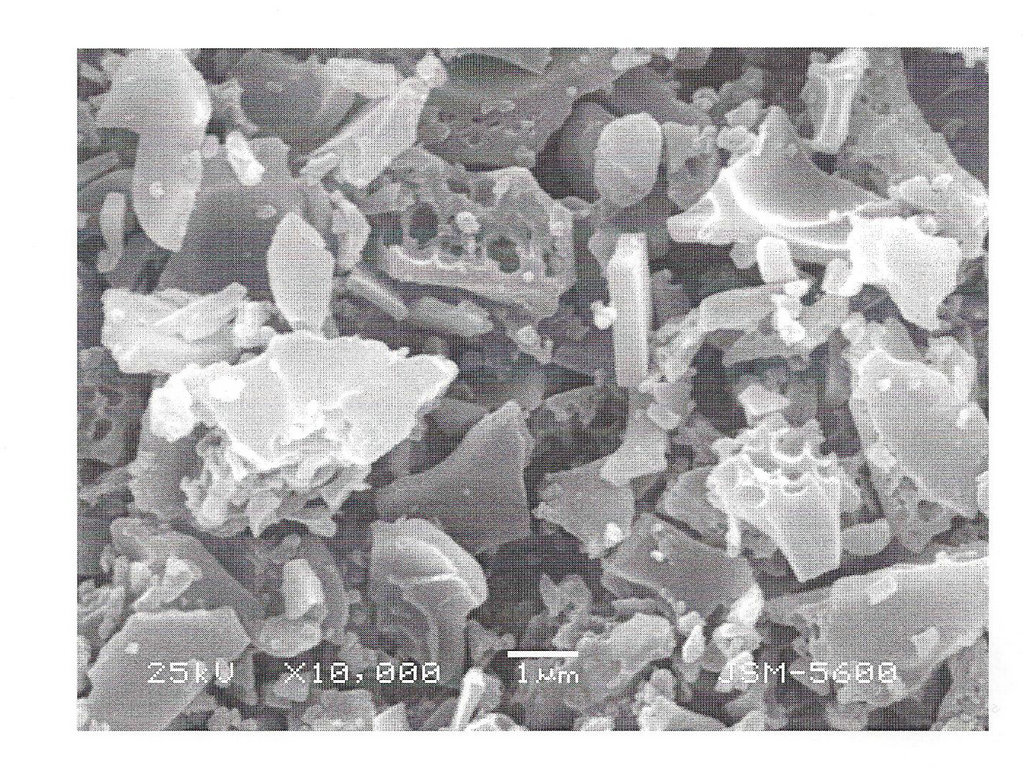

[0018] Put zinc nitrate, aluminum nitrate and citric acid into a beaker, wherein the molar ratio of nitrate to citric acid is 0.8, and the aluminum content is 1.0 at%, add an appropriate amount of deionized water, stir to fully dissolve, and then place at a constant temperature Continue heating and stirring on the magnetic stirrer, and control the temperature of the solution between 60°C and 70°C; when the solution forms a sol, control the temperature of the sol at about 80°C until a light yellow gel is formed, then stop heating and stirring; Put the beaker containing the gel into an oven preheated to 180°C for 4 hours, wait for it to cool down to room temperature naturally, and take out the fluffy precursor powder; place the precursor in a box-type resistance furnace at 5°C / The temperature was raised to 800°C at a rate of 1 min, held for 2 hours, and then naturally cooled to room temperature to obtain porous grid rod-shaped aluminum-doped ZnO nanomaterials.

example 2

[0020] Put zinc nitrate, aluminum nitrate and citric acid into a beaker, wherein the molar ratio of nitrate to citric acid is 1.0, and the aluminum content is 1.0 at%, add an appropriate amount of deionized water, stir to fully dissolve, and then place at constant temperature Continue heating and stirring on the magnetic stirrer, and control the temperature of the solution at 60°C to 70°C; when the solution forms a sol, control the temperature of the solution at 80°C until a light yellow gel is formed, then stop heating and stirring; Place the beaker of glue in an oven preheated to 180°C and heat it for 5 hours, and wait for it to cool naturally to room temperature to obtain a fluffy precursor powder; place the precursor in a box-type resistance furnace and heat up at a rate of 5°C / min to 800° C., heat preservation for 3 hours, and then naturally cool to room temperature to obtain porous grid rod-shaped aluminum-doped zinc oxide nanomaterials.

example 3

[0022] Put zinc nitrate, aluminum nitrate and citric acid into a beaker, wherein the molar ratio of nitrate to citric acid is 1.0, and the aluminum content is 1.5 at%, add an appropriate amount of deionized water, stir to fully dissolve, and then place at a constant temperature Continue heating and stirring on the magnetic stirrer, and control the temperature of the solution at 60°C to 70°C; when the solution forms a sol, control the temperature of the solution at 80°C until a light yellow gel is formed, then stop heating and stirring; Put the beaker of the gel into an oven preheated to 180°C for 3 hours, wait for it to cool naturally to room temperature, take out the fluffy precursor powder; The temperature was raised to 700° C., kept at a temperature of 2 hours, and then naturally cooled to room temperature to obtain porous grid rod-shaped aluminum-doped zinc oxide nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com