Self-compacting concrete for foundation of high speed railway turnout plate

A self-compacting concrete, high-speed railway technology, applied in the field of concrete, can solve the problems that are not completely suitable for self-compacting concrete construction and durability requirements, and achieve the effects of reducing segregation and bleeding, improving workability, and strengthening bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: a kind of weight and the percentage of each component of the self-compacting concrete that is used for high-speed railway turnout plate base are:

[0031] Cement 263kg, accounting for 11.1%; fly ash 154kg, accounting for 6.5%; slag powder 78kg, accounting for 3.3%; fine aggregate 820kg, accounting for 34.7%; coarse aggregate 815kg, accounting for 34.4%; water 175kg , accounting for 7.4%; water reducing agent 5.50kg, accounting for 0.23%; expansion agent 55kg, accounting for 2.3%;

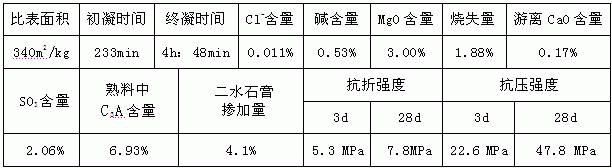

[0032] The cement is Portland cement, the specific surface area is ≤350m2 / kg, and the alkali content is ≤0.80%; the fly ash is Class I fly ash of Class F, the fineness is ≤12%, and the water demand ratio is ≤95% , loss on ignition ≤ 5.0%.

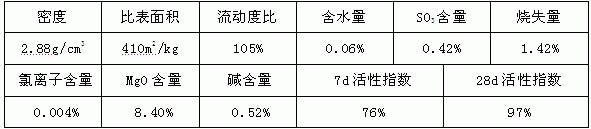

[0033] The slag powder has a density ≥ 2.8g / cm3, a specific surface area of 350m2 / kg-500 m2 / kg, a loss on ignition ≤ 3.0%, a fluidity ratio ≥ 95%, and a 28d activity index ≥ 95%.

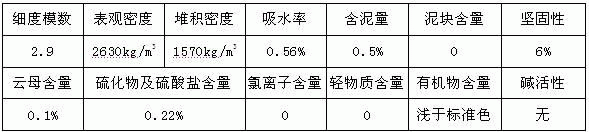

[0034] For the fine aggregate, clean natural river sand...

Embodiment 2

[0045] Embodiment two: a kind of weight and the percentage of each component of the self-compacting concrete that is used for high-speed railway turnout plate base are:

[0046] Cement 274kg, accounting for 11.6%; fly ash 145kg, accounting for 6.1%; slag powder 93kg, accounting for 3.9%; fine aggregate 813kg, accounting for 34.3%; coarse aggregate 815kg, accounting for 34.4%; water 175kg , accounting for 7.4%; water reducing agent 5.00kg, accounting for 0.21%; expansion agent 50kg, accounting for 2.1%.

[0047] The cement is Portland cement, the specific surface area is ≤350m2 / kg, and the alkali content is ≤0.80%; the fly ash is Class I fly ash of Class F, the fineness is ≤12%, and the water demand ratio is ≤95% , loss on ignition ≤ 5.0%.

[0048] The slag powder has a density ≥ 2.8g / cm3, a specific surface area of 350m2 / kg-500 m2 / kg, a loss on ignition ≤ 3.0%, a fluidity ratio ≥ 95%, and a 28d activity index ≥ 95%.

[0049] For the fine aggregate, clean natural river sand...

Embodiment 3

[0060] Embodiment three: a kind of weight and the percentage of each component of the self-compacting concrete that is used for high-speed railway turnout plate base are

[0061] Cement 270kg, accounting for 11.3%; fly ash 160kg, accounting for 6.7%; slag powder 84kg, accounting for 3.5%; fine aggregate 810kg, accounting for 34%; coarse aggregate 815kg, accounting for 34.2%; water 175 ㎏, accounting for 7.4%; water reducing agent 6.00kg, accounting for 0.25%; expansion agent 60kg, accounting for 2.5%;

[0062] The cement is made of ordinary Portland cement with a specific surface area of ≤350m2 / kg and an alkali content of ≤0.80%; the fly ash is made of Class I fly ash of Class F with a fineness of ≤12% and a water demand ratio of ≤95 %, loss on ignition ≤5.0%.

[0063] The slag powder has a density ≥ 2.8g / cm3, a specific surface area of 350m2 / kg-500 m2 / kg, a loss on ignition ≤ 3.0%, a fluidity ratio ≥ 95%, and a 28d activity index ≥ 95%.

[0064] For the fine aggregate, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com