Inorganic dry powder sand textured architectural coating and production method thereof

A technology of sand wall-like coating and inorganic dry powder, which is applied in the field of inorganic dry powder sand wall-like architectural coatings, can solve the problems of poor fire resistance and insignificant method effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] In this example, the components include:

[0120] Colored sand (20 mesh) 300g;

[0121] Potassium silicate 100g;

[0122] Aluminum phosphate 5g;

[0123] EVA redispersible latex powder 20g;

[0124] Color stone powder (250 mesh) 200g

[0125] Defoamer 1g;

[0126] Thickener 1g.

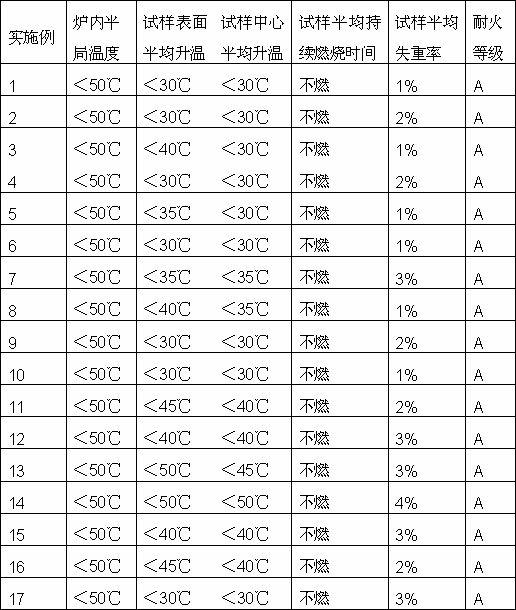

[0127] Dry-mix the above components to prepare the inorganic dry powder sand wall coating, add it into water, stir evenly, and then start the construction operation, which can be carried out by spraying, roller coating or brushing, and its performance is in accordance with the construction industry standards of the People's Republic of China JG / T 26-2002 "Inorganic Architectural Coatings for Exterior Walls" was tested, and the VOC content was tested according to the national standard of the People's Republic of China GB 18582-2008 "Limits of Harmful Substances in Interior Decoration Materials and Interior Wall Coatings". The test results are shown in Table 1 and Table 2.

Embodiment 2

[0129] In this example, the components include:

[0130] Colored sand (70 mesh) 400g;

[0131] Potassium silicate 250g;

[0132] Aluminum phosphate 50g;

[0133] EVA redispersible latex powder 60g;

[0134] Color stone powder (250 mesh) 400g

[0135] Defoamer 5g;

[0136] Thickener 5g.

[0137] Dry-mix the above components to prepare the inorganic dry powder sand wall coating, add it into water, stir evenly, and then start the construction operation, which can be carried out by spraying, roller coating or brushing, and its performance is in accordance with the construction industry standards of the People's Republic of China JG / T 26-2002 "Inorganic Architectural Coatings for Exterior Walls" was tested, and the VOC content was tested according to the national standard of the People's Republic of China GB 18582-2008 "Limits of Harmful Substances in Interior Decoration Materials and Interior Wall Coatings". The test results are shown in Table 1 and Table 2.

Embodiment 3

[0139] In this example, the components include:

[0140] Colored sand (28 mesh) 310g;

[0141] Sodium silicate 233g;

[0142] ZnO 46g;

[0143] EVA redispersible latex powder 34g;

[0144] Color stone powder (250 mesh) 222g

[0145] Defoamer 3g;

[0146] Thickener 2g.

[0147] Dry-mix the above components to prepare the inorganic dry powder sand wall coating, add it into water, stir evenly, and then start the construction operation, which can be carried out by spraying, roller coating or brushing, and its performance is in accordance with the construction industry standards of the People's Republic of China JG / T 26-2002 "Inorganic Architectural Coatings for Exterior Walls" was tested, and the VOC content was tested according to the national standard of the People's Republic of China GB 18582-2008 "Limits of Harmful Substances in Interior Decoration Materials and Interior Wall Coatings". The test results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com