A kind of manufacturing method of imitating natural travertine flexible sheet

A flexible sheet material and manufacturing method technology, applied in coating, textile and papermaking, building components, etc., can solve the problems of mold discontinuity, low output, complex production process, etc., achieve fast drying speed, good effect, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

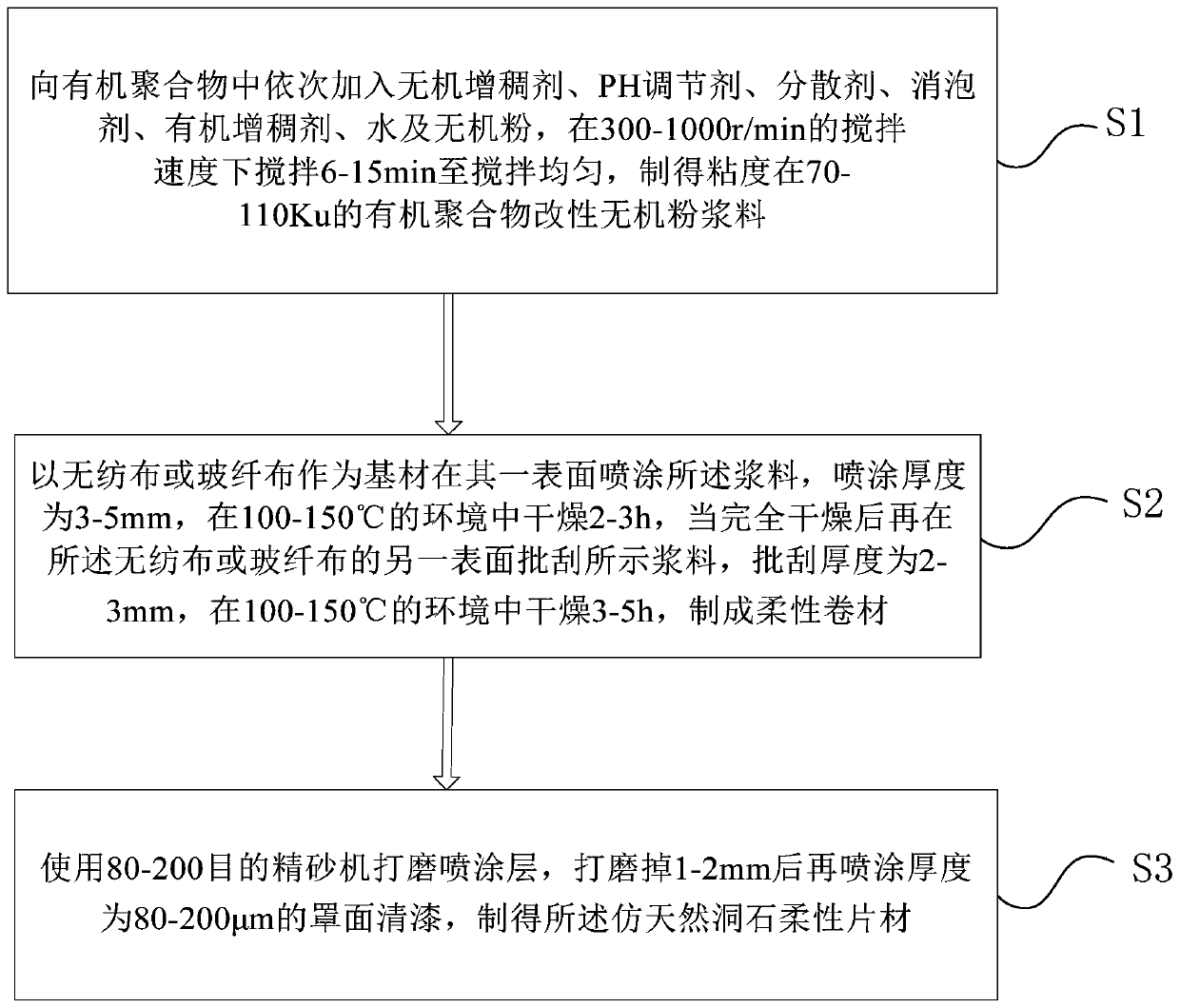

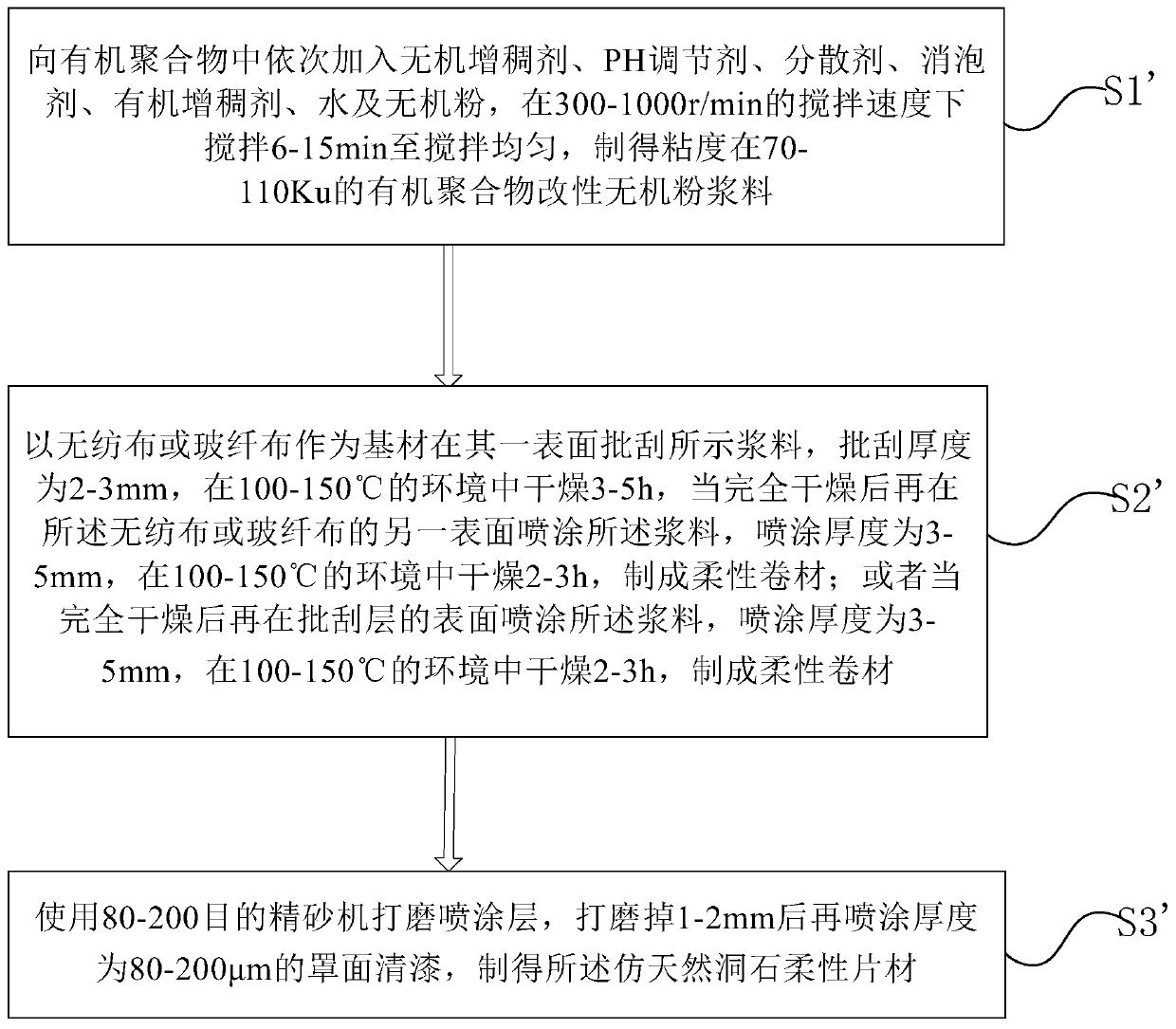

Method used

Image

Examples

Embodiment 1

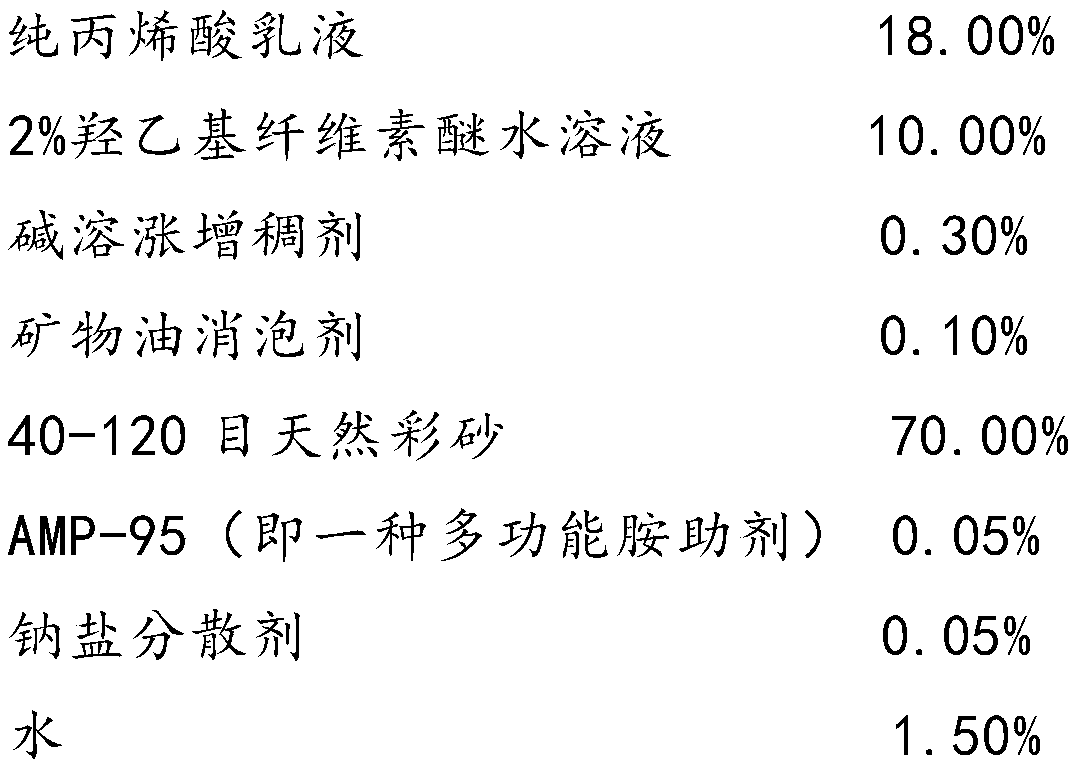

[0049] The weight content of the selected organic polymer, inorganic thickener, pH regulator, dispersant, defoamer, organic thickener, inorganic powder and water is also as follows:

[0050]

[0051] The production method of this embodiment is: use a disperser to disperse for 6 minutes under the condition of 300r / min, the viscosity of the slurry is 70ku, spray it on the surface of the continuous non-woven fabric, control the air pressure of the spray gun to 0.4MPa, and the material pressure to 0.4MPa , the thickness of spraying is 3mm, after spraying, irregular concave-convex shapes are formed on the surface, and it is dried in a 150°C oven for 2 hours. Dry for 5 hours, and roll up after complete drying. After the sprayed layer with a thickness of 3 mm is polished to 1 mm by a 120-mesh fine sand machine, the finish varnish is sprayed with a thickness of 80 μm. Since most of the protrusions on the surface of the sprayed coating have been flattened, while the concave parts a...

Embodiment 2

[0053] The weight content of selected organic polymer, inorganic thickener, pH regulator, dispersant, defoamer, organic thickener, inorganic powder and water is as follows:

[0054]

[0055]

[0056] The production method of this embodiment is: use a disperser to disperse for 15 minutes under the condition of 1000r / min, the viscosity of the slurry is 110ku, spray on the surface of the continuous non-woven fabric, control the air pressure of the spray gun to 0.20MPa, and the material pressure to 0.6MPa , The spraying thickness is 5mm. Due to the high viscosity of this slurry, it can form large unevenness on the surface after spraying with low air pressure. Dry through a 150°C oven for 3 hours, wind up after complete drying, and then scrape the slurry on the back of the non-woven fabric with a thickness of 2mm, dry through a 150°C oven for 3 hours, and wind up after completely drying. After the sprayed layer with a thickness of 5 mm is polished to 2 mm by an 80-mesh fine s...

Embodiment 3

[0058] The weight content of selected organic polymer, inorganic thickener, pH regulator, dispersant, defoamer, organic thickener, inorganic powder and water is as follows:

[0059]

[0060]

[0061] The production method of this embodiment is: use a disperser to disperse for 10 minutes under the condition of 700r / min, the viscosity of the slurry is 100ku, spray it on the surface of the continuous glass fiber cloth, control the air pressure of the spray gun to 0.30MPa, and the material pressure to 0.5MPa , the thickness of spraying is 4mm, dried in a 110°C oven for 3 hours, and rolled up after complete drying, and then scraped the slurry on the back of the glass fiber cloth with a thickness of 2mm, dried in a 120°C oven for 4 hours, and rolled up after complete drying. After the 4mm thick sprayed layer is polished by an 80-mesh fine sand machine for 1 mm, then lightly polished by a 120-mesh fine sand machine to about 200 μm, and the finish varnish is sprayed with a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com