Rubber additive pre-dispersion, preparation method thereof and method for preparing rubber additives

A pre-dispersion and additive technology, which is applied in the field of rubber additive preparation, can solve the problems of product physical and mechanical properties reduction, affecting product qualification rate, product appearance defects, etc., to reduce the time of material mixing, simple manufacturing process, and dispersibility Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the rubber additive predispersion comprises the following steps: (1) After weighing EPDM (ethylene propylene diene monomer), CPE (resin-type chlorinated polyethylene) and stearic acid in a certain proportion, add them to the banburying (2) Turn on the internal mixer and knead for 5 to 10 minutes until the mixture softens into a soft mass, then stop the kneading and cut the material for later use to obtain a rubber additive pre-dispersion.

[0028] Such as figure 1 As shown, the preparation method of the rubber additive includes the following steps: a. Calculated by weight, 8% to 15% of the rubber additive predispersion, 50% to 80% of the additive dry powder to be pre-dispersed and 2% to Put 10% rubber processing oil into the internal mixer for mixing, wherein the mixing time is 5 to 10 minutes, the mixing temperature is controlled between 65°C and 110°C, and the internal mixer is turned on once during the mixing process, so that The sizing mat...

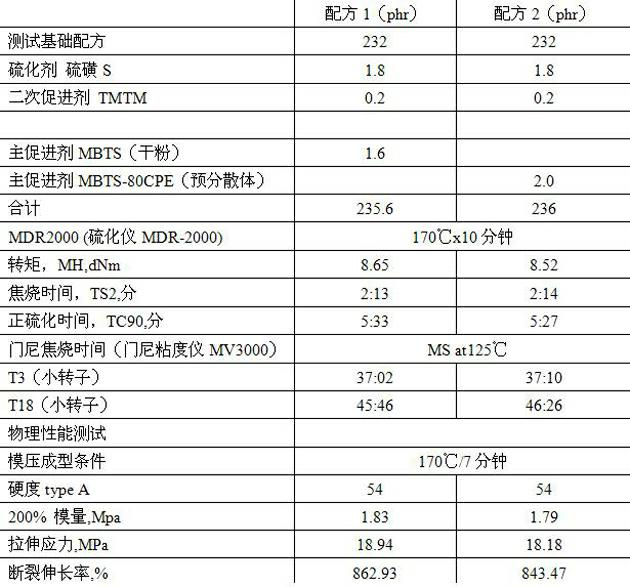

Embodiment 1

[0030] Embodiment one: Make dry powder vulcanization accelerator MBTS into granular products

[0031] Such as figure 1 As shown, weigh according to figure 2 Put 4.72KG of the pre-prepared rubber additive pre-dispersion shown in Attached Table 1 into the internal mixer, add 36 KG of dry powder MBTS to be dispersed, start the internal mixer, slowly add white mineral oil for rubber processing, Put down the pressurized weight and the dust cover to complete the set mixing time, about 5 to 8 minutes in total. During this period, the dust cover is opened, and the pressure weight is raised, so that the rubber material in the mixing chamber can be freely rolled twice to ensure complete mixing and uniformity. After the materials in the mixing chamber are completely mixed to form soft and moist lumps, they can be fed into the extruder for pelletizing. Cylindrical fluid rubber particles with a diameter of about 5 mm and a length of about 3 to 5 mm can be obtained after being cooled ...

Embodiment 2

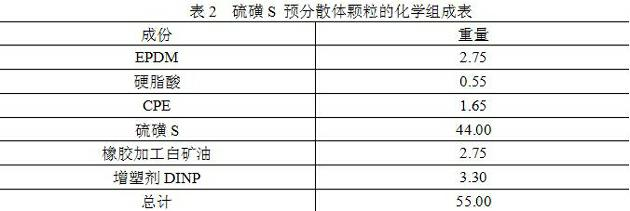

[0032] Embodiment two: Preparation of dry powdered rubber vulcanizing agent sulfur S into granular products

[0033] Such as figure 1 As shown, weigh according to image 3 Put 4.95KG of the pre-prepared rubber additive pre-dispersion shown in Attached Table 2 in the internal mixer, add dry powder sulfur S44KG to be dispersed, start the internal mixer, slowly add white mineral oil for rubber processing, put it down and pressurize The mound and the dust cover complete the set mixing time, about 5 to 8 minutes in total, during which the dust cover is opened and the pressure mound is raised, so that the rubber in the mixing chamber can turn over freely twice to ensure complete mixing uniform. After the materials in the mixing chamber are completely mixed to form soft and moist lumps, they can be fed into the extruder for pelletizing. Cylindrical fluid rubber particles with a diameter of about 5 mm and a length of about 3 to 5 mm can be obtained after being cooled by a blast ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com