Preparation method for silicate luminescent material

A technology of luminescent material and silicate, which is applied in the field of preparation of silicate luminescent material, and achieves the effects of high yield, simple preparation process and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

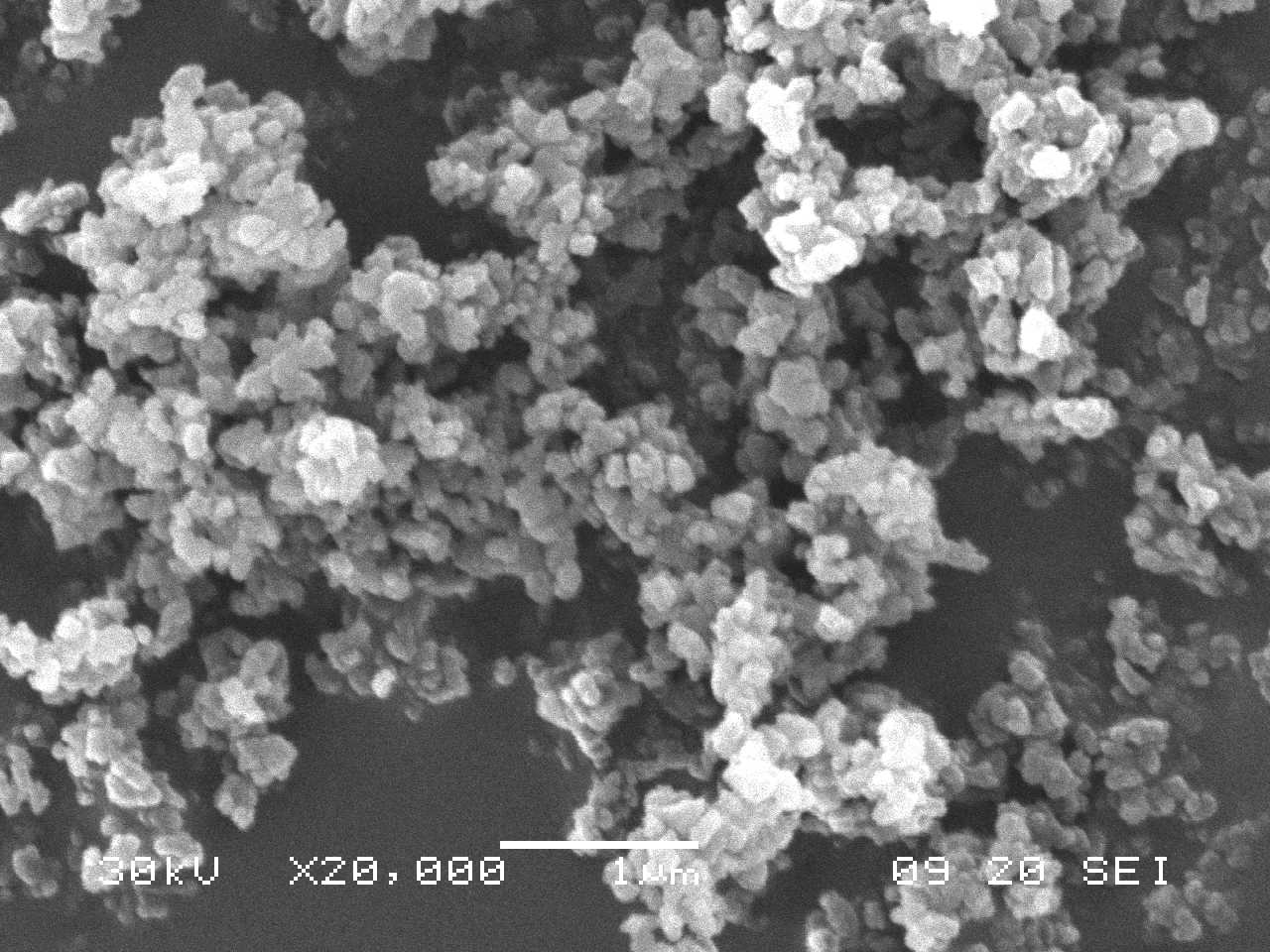

[0032] With Sr(NO 3 ) 2 (AR), Mg(NO 3 ) 2 ·6H 2 O (AR), C 8 h 20 o 4 Si (AR), Eu 2 o 3 (99.99%) and Dy 2 o 3 (99.99%) is the starting material, according to Sr 1.97 MgSi 2 o 7 :0.01Eu 2+ ,0.02Dy 3+ The stoichiometric ratio (C8 h 20 o 4 Si excess 5%) were accurately weighed. Will Eu 2 o 3 and Dy 2 o 3 Dissolve with concentrated nitric acid and dilute with water-ethanol mixture with a volume ratio of 2:1, then add Sr(NO 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O, C 8 h 20 o 4 Si, precipitant urea, stir to dissolve, the total concentration of metal ions is 0.5 mol / L, the amount of urea ( n 尿 , mol): cation content ( n 阳 , mol)=6 (cations refer to metal ions and silicon ions, the same below), transfer the mixed solution to a stainless steel reactor lined with polytetrafluoroethylene, the filling degree is 80%, and keep it at 95°C for 24h to obtain cations The precipitated slurry was centrifuged, the supernatant was discarded, washed with ethanol, vacuum dried ...

Embodiment 2

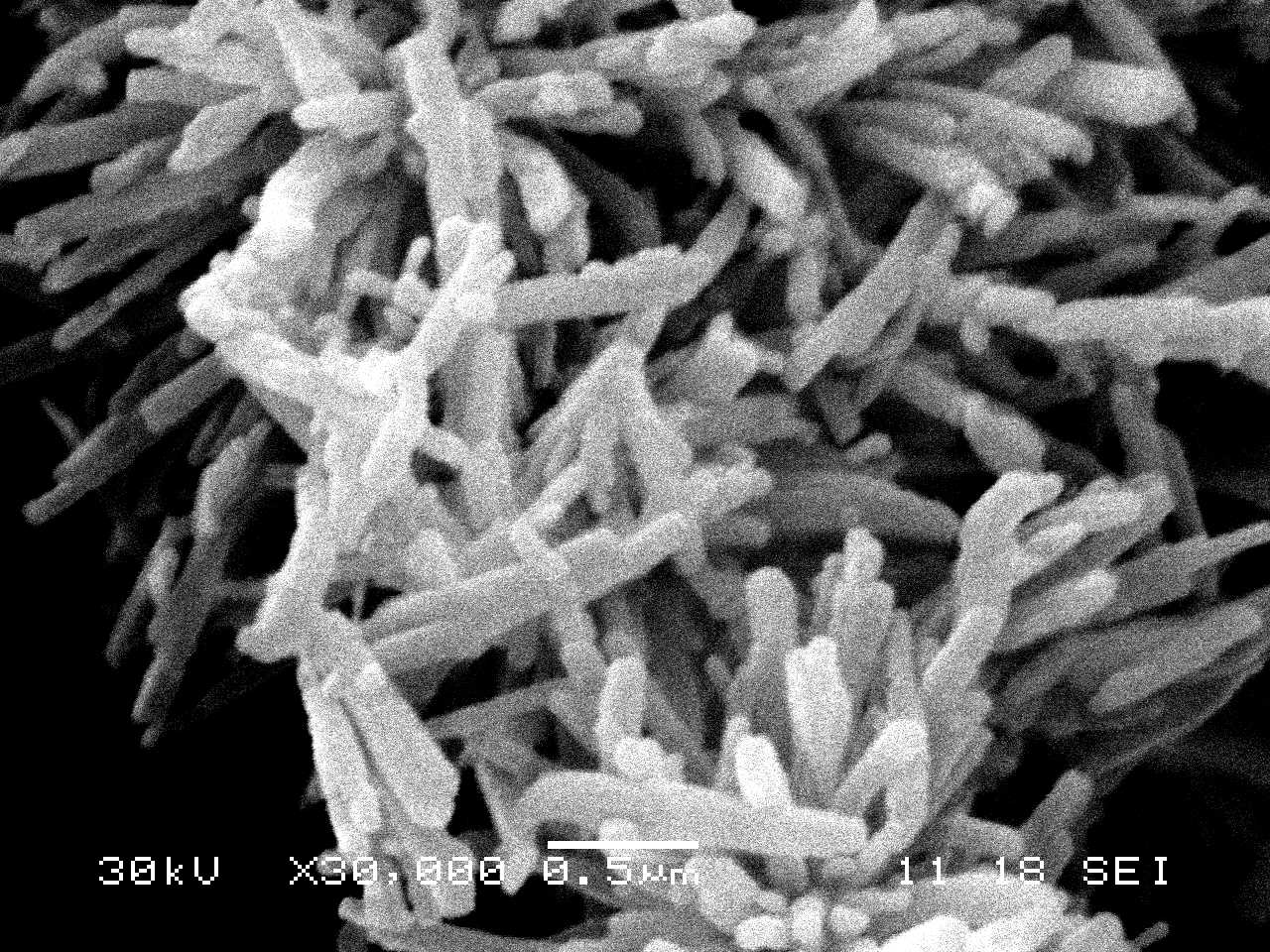

[0034] With Sr(CH 3 COO) 2 (AR), Mg(CH 3 COO) 2 4H 2 O (AR), C 8 h 20 o 4 Si (AR), Eu 2 o 3 (99.99%) and Dy 2 o 3 (99.99%) is the starting material, according to Sr 1.97 MgSi 2 o 7 :0.01Eu 2+ ,0.02Dy 3+ The stoichiometric ratio (C 8 h 20 o 4 Si excess 10%) were accurately weighed. Will Eu 2 o 3 and Dy 2 o 3 Dissolve with concentrated nitric acid and dilute with a water-ethanol mixture with a volume ratio of 1:1, then add Sr(CH 3 COO) 2 , Mg(CH 3 COO) 2 4H 2 O, C 8 h 20 o 4 Si, precipitant urea, template agent polyethylene glycol (molecular weight 2000), stirring to dissolve, the total concentration of metal ions is 0.5 mol / L, the amount of urea ( n 尿 , mol): cation content ( n 阳 , mol)=9, the amount of polyethylene glycol is 5wt% of the theoretical yield of the product. Transfer the mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, with a filling degree of 80%, and keep it warm at 105°C for 12 hours. W...

Embodiment 3

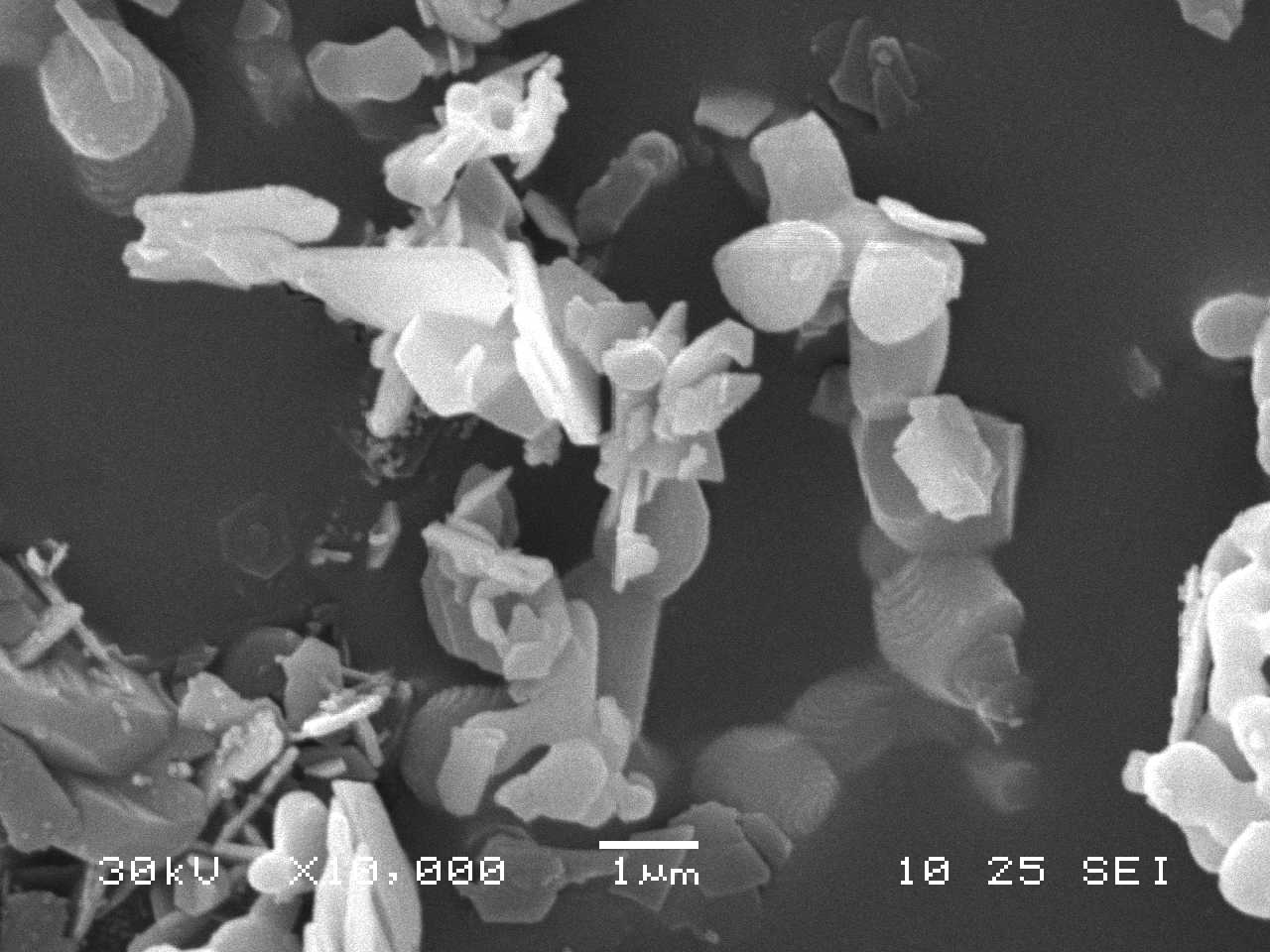

[0036] SrCO 3 (AR), MgO (AR), C 8 h 20 o 4 Si (AR), Eu 2 o 3 (99.99%) and Dy 2 o 3 (99.99%) is the starting material, according to Sr 1.97 MgSi 2 o 7 :0.01Eu 2+ ,0.02Dy 3+ The stoichiometric ratio (C 8 h 20 o 4 Si excess 8%) were accurately weighed. SrCO 3 , MgO, Eu 2 o 3 and Dy 2 o 3 Dissolve with concentrated nitric acid and dilute with a water-ethanol mixture with a volume ratio of 3:1, then add C 8 h 20 o 4 Si, precipitant urea, template agent β-cyclodextrin, stirred to dissolve, the total concentration of metal ions is 0.5 mol / L, the amount of urea ( n 尿 , mol): cation content ( n 阳 , mol)=12, the dosage of β-cyclodextrin is 3wt% of the theoretical yield of the product. Transfer the mixed solution to a polytetrafluoroethylene-lined stainless steel reaction kettle with a filling degree of 80%, and keep it at 95°C for 18 hours to obtain the precipitated slurry of cationic precipitates. Wash, dry in a vacuum oven at 100°C, and then calcinate for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com