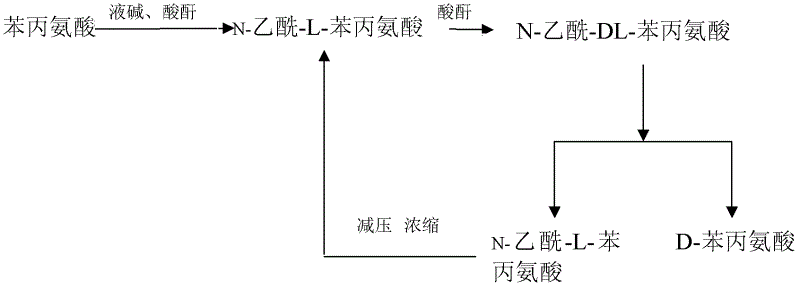

Method for producing D-phenylalanine by using L-phenylalanine as raw material

A technology for phenylalanine and raw materials, which is applied in the field of D-enzyme splitting and preparing D-phenylalanine, can solve the problems of high cost, long process flow, low optical purity and the like, and achieves low cost, simple process flow and high product quality. high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Acylation of L-phenylalanine

[0023] Weigh 300kgL-phenylalanine and dissolve it in 800L pure water, adjust the pH to 8-9 with 30% NaOH solution, about 200L of 30% NaOH is required. After the dissolution is complete, control the solution temperature at 30-35°C, and add acetic anhydride dropwise until the solution reacts with ninhydrin without color change, and the reaction is complete.

[0024] Acetyl-L-phenylalanine racemization

[0025] Use 30% hydrochloric acid to adjust the pH to 4-5 with about 0.8m3 acetylated-L-phenylalanine acylation solution with a concentration of about 0.04kg / L obtained in the previous step, add acetic anhydride dropwise at 60°C for racemization, Detection of racemate After the reaction, add 30% hydrochloric acid to adjust the pH to 1-2, cool and crystallize, filter out the crystals and dry them to obtain 30 kg of acetyl-DL-phenylalanine.

[0026] Resolution and separation of D-phenylalanine

[0027] Weigh 200kg of acetyl-DL-phenylalanine...

Embodiment 2

[0029] Acylation of L-phenylalanine

[0030] Weigh 330kgL-phenylalanine and dissolve it in 800L pure water, adjust the pH to 10-11 with 30% NaOH solution, about 200L of 30% NaOH is required. After the dissolution is complete, control the solution temperature at 35-40°C, and add acetic anhydride dropwise until the solution reacts with ninhydrin without color change, and the reaction is complete.

[0031] Acetyl-L-phenylalanine racemization

[0032] Use 30% hydrochloric acid to adjust the pH to 5-6 with about 0.8m3 acetylated-L-phenylalanine concentration of 0.04kg / L obtained in the previous step, add acetic anhydride dropwise at 70°C for racemization, and detect racemic solution After the reaction, add 30% hydrochloric acid to adjust the pH to 1-2, cool and crystallize, filter out the crystals and dry them to obtain 30 kg of acetyl-DL-phenylalanine.

[0033] Resolution and separation of D-phenylalanine

[0034] Weigh 200kg of acetyl-DL-phenylalanine to prepare a solution w...

Embodiment 3

[0036] Acylation of L-phenylalanine

[0037] Weigh 400kgL-phenylalanine and dissolve it in 800L pure water, and adjust the pH to 12-13 with 30% NaOH solution, and about 200L of 30% NaOH is required. After the dissolution is complete, control the solution temperature at 35-40°C, and add acetic anhydride dropwise until the solution reacts with ninhydrin without color change, and the reaction is complete.

[0038] Acetyl-L-phenylalanine racemization

[0039] Use 30% hydrochloric acid to adjust the pH to 5-6 with about 0.8m3 acetylated-L-phenylalanine concentration of 0.04kg / L obtained in the previous step, add acetic anhydride dropwise at 90°C for racemization, and detect racemic solution After the reaction, add 30% hydrochloric acid to adjust the pH to 3-4, cool and crystallize, filter out the crystals and dry them to obtain 30 kg of acetyl-DL-phenylalanine.

[0040] Resolution and separation of D-phenylalanine

[0041] Weigh 200kg of acetyl-DL-phenylalanine to prepare a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com