Water-proof heat-preserving metal roof system

A technology of metal roofing and pipe boots, which is applied in the direction of roofing, roof cladding, and roofs using flat/curved panels, etc. It can solve the problems of reduced roof insulation effect, damage to roof insulation layer, water leakage, etc., and achieves convenient operation and airtightness Good performance, beautiful installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

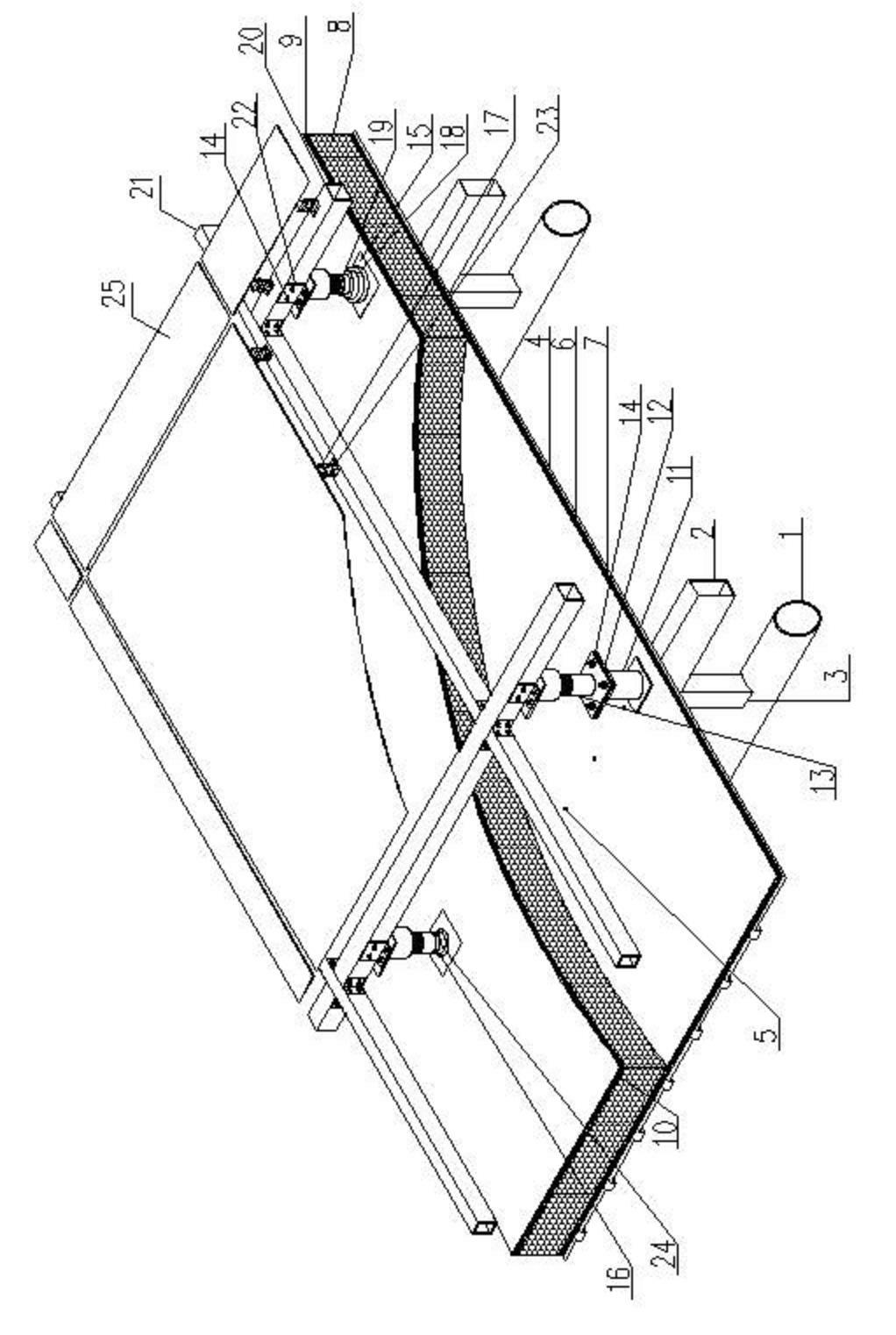

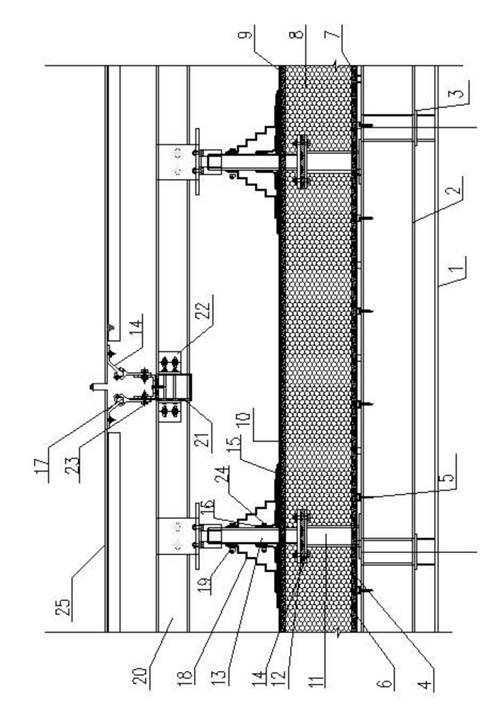

[0036] A waterproof and heat-retaining metal roof system, which consists of: decorative panels 25, vertically and horizontally intersecting main keels 20 and secondary keels 21, pipe boots, purlins 2, and lower steel structure 1. The decorative panels 25 are fixed on the connectors, The other end of the connector is fixed on the keel, the main keel 20 is fixed on the purlin 2 through the adjustment support, and the steel plate is laminated on the purlin, according to the order from top to bottom The sequence: the waterproof layer 10, the protective layer 9, the insulation layer 8, and the gas barrier layer 7 are arranged on the steel plate layer, and the purlin support 3 supports the purlin 2 on the lower steel structure 1. The upper deck decorative panel 25 of the roof adopts an aluminum-plastic panel or an aluminum veneer or a honeycomb aluminum panel or a titanium-zinc panel or a copper panel.

Embodiment 2

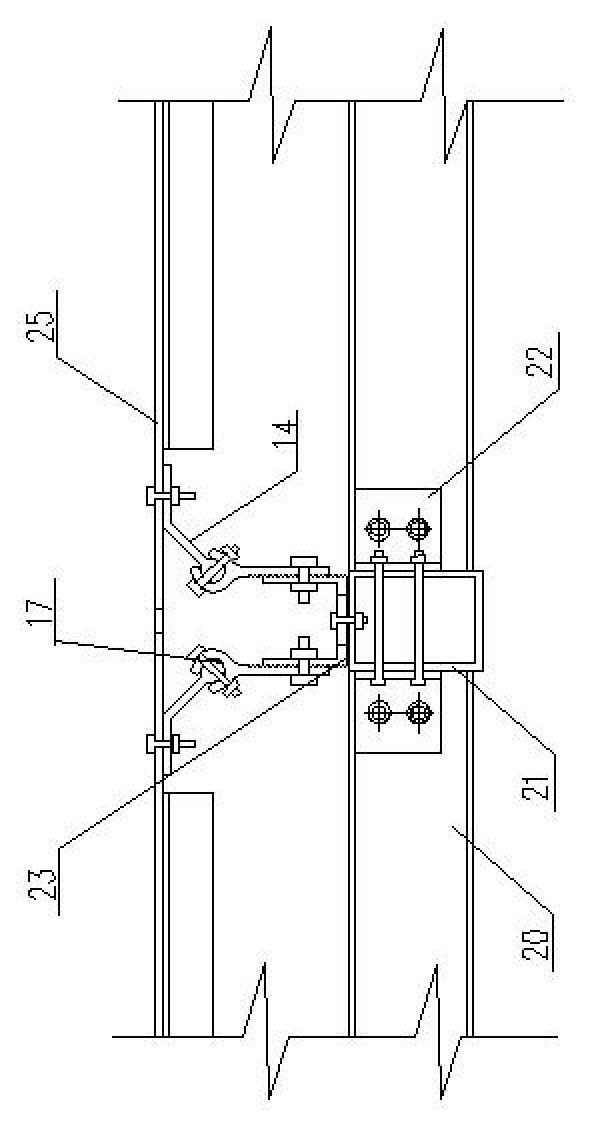

[0038] In the waterproof and thermal insulation metal roof system described in Embodiment 1, the connecting piece 24 is formed by pinning the upper fixing piece and the fork of the lower connecting plate, and the connecting piece 24 is fixed on the secondary keel 21 or On the main keel 20. The connecting plate at the bottom of the connector and the angle code 23 are all provided with slotted holes, and are connected with grooved bolts 17, which can effectively adjust the height difference. In this way, the angle-adjustable and height-adjustable connection relationship between the keel and the decorative plate 25 is formed by the connecting piece connecting the decorative plate and the main keel 20 or the secondary keel 21 .

Embodiment 3

[0040] In the waterproof and thermal insulation metal roof system described in Embodiment 1, the adjustment support includes a base 11 installed on the purlin, and the base 11 and the upper adjustment member 13 are connected by bolts through the heat insulation pad 12, and the The above-mentioned tube boot 16 is set on the outside of the above-mentioned upper adjustment part, and the lower part is clamped from the outer upper end by a clamping ring and adhered to the above-mentioned waterproof layer 10, and a finished glue is added between the tube boot and the waterproof layer. Pad 15 plays the protective role of vapor barrier. The outer side of the pipe shoe 16 is covered with a pointed pipe shoe 18 and is clamped from the upper end of the outside by a clamping ring 19. The lower part is bonded to the waterproof layer 10 with the finished rubber pad 15 added. The upper part is The adjusting part is bolted to the main keel 20 through the angle codes 22 and 14. The 11 weeks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com