Motor parameter detector

A technology of motor parameters and detectors, applied in the direction of motor generator testing, etc., can solve the problems of high price and complex system construction, achieve high degree of automation, overcome small reserves, and improve system stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

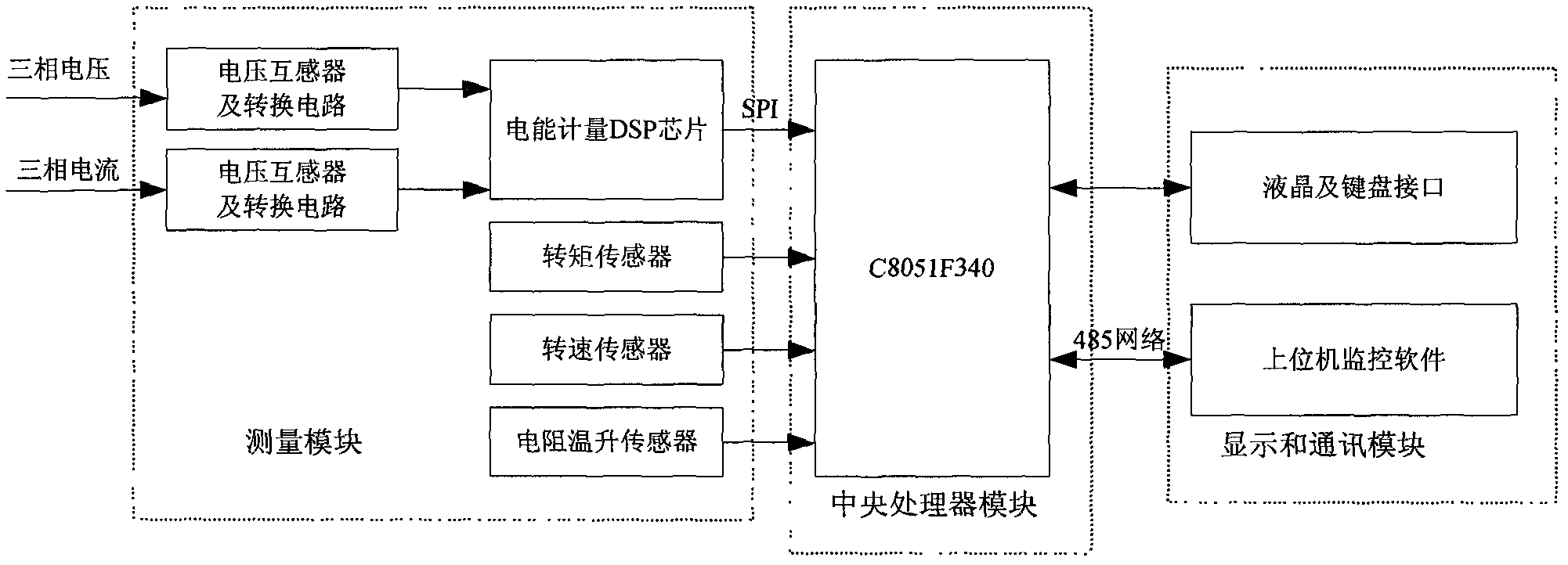

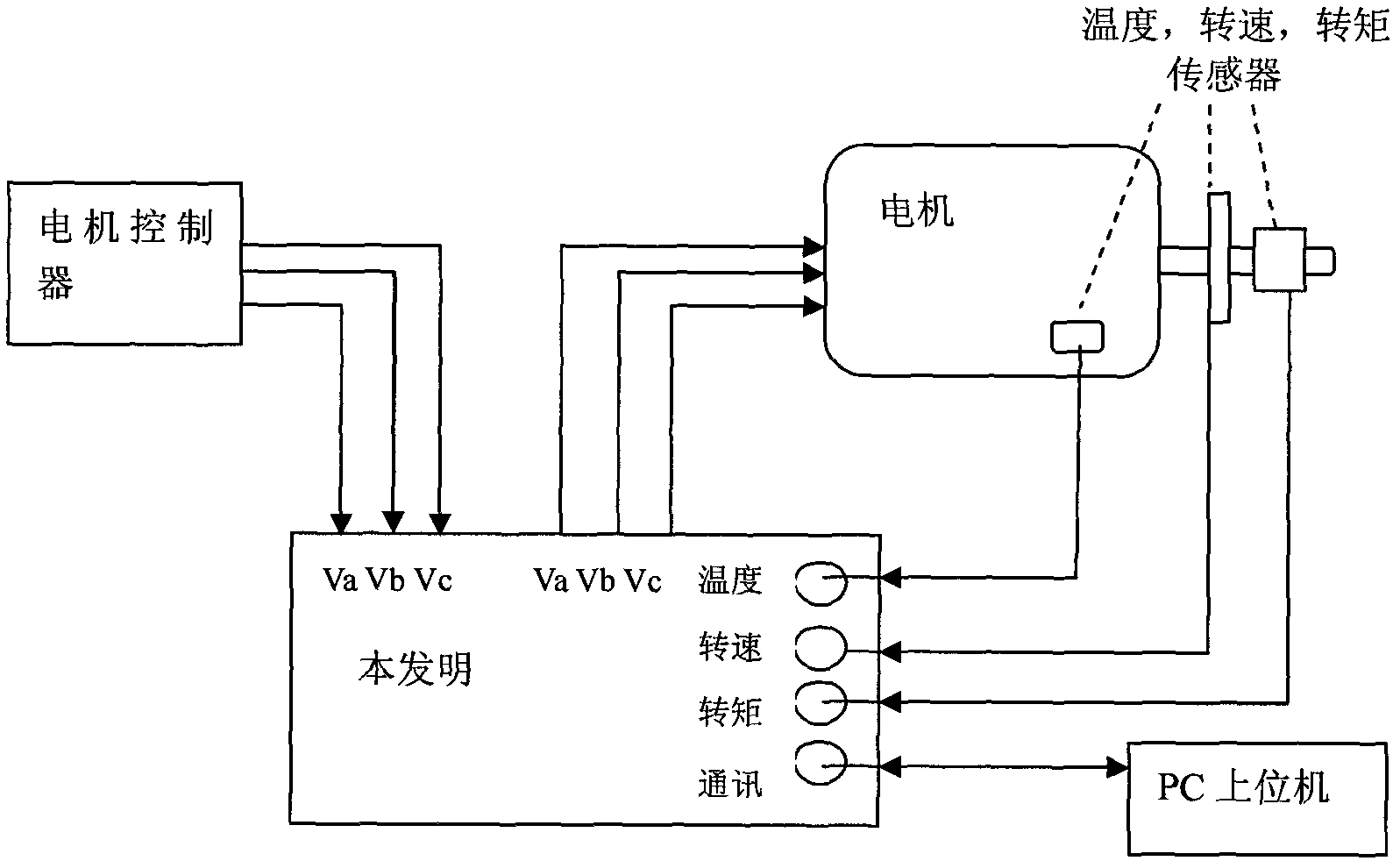

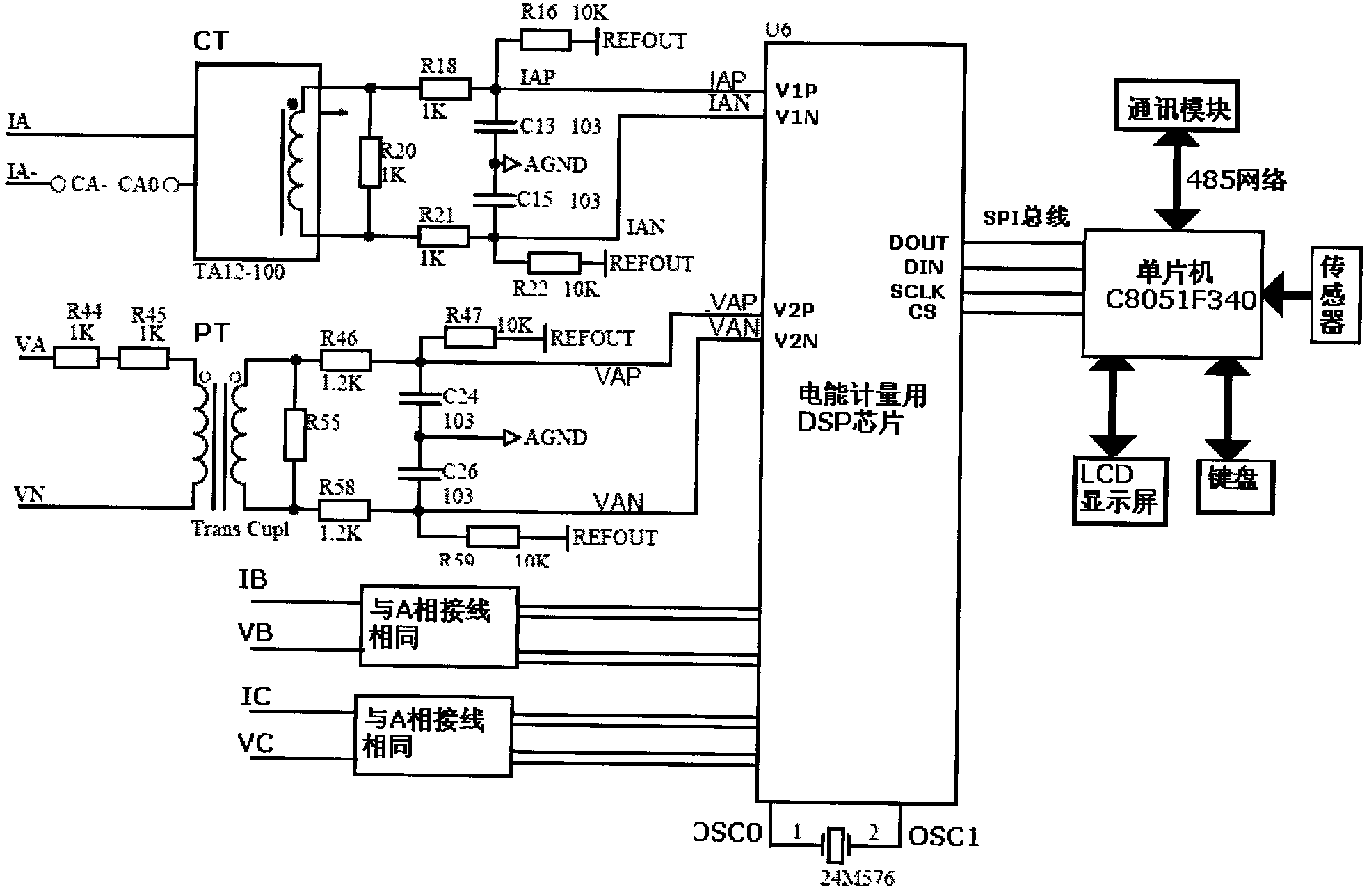

[0020] The motor parameter detector includes a hardware platform composed of a central processing unit MCU module, a measurement module, a display module and a communication module. Specific as figure 1 As shown, the system uses C8051F340 single-chip microcomputer as the central processing unit to form the main control circuit, wherein the central processing unit MCU is connected with the DSP chip for electric energy measurement through the SPI bus, and is connected with the torque sensor, speed sensor, winding temperature rise sensor, liquid crystal screen, keyboard and related interface circuits, and communicate with PC host computer software through 485 network, and further analyze and manage the uploaded data on the computer to realize human-computer interaction; among them, the DSP chip for electric energy measurement is connected with the voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com